The angle of the bit just depends on the detail you need. I use 60deg for most.

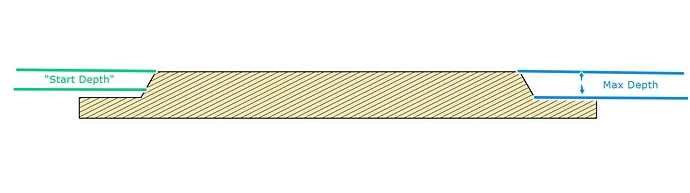

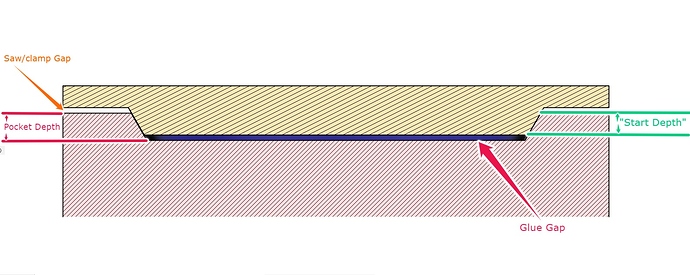

The “Start Depth” is the amount the inlay will insert into the pocket before the design matches up. You want this to be most of your pocket depth.

Glue Gap = Female Pocket Depth - Male Start Depth

Saw Gap = Male Max Depth - Male Start Depth

I don’t see a reason to go more than 5mm or 0.2" on a pocket depth.

Glue gap isn’t as much for glue as it is for clamp force (works better when you REALLY clamp it).

Saw gap only needs to be bigger if you’re actually sawing the excess inlay scrap off (I use the machine to face it off). You do want that gap to be at least the same as the glue gap for clamping (again, smash the inlay in there).

There’s nothing crazy to it. When you use the same bit, the angles match up. The key is “tricking” it to match up part way down the male inlay. Create’s “Start Depth” takes care of that for you, but you can just set Z-zero below the surface to achieve the same thing.