as requested on support…

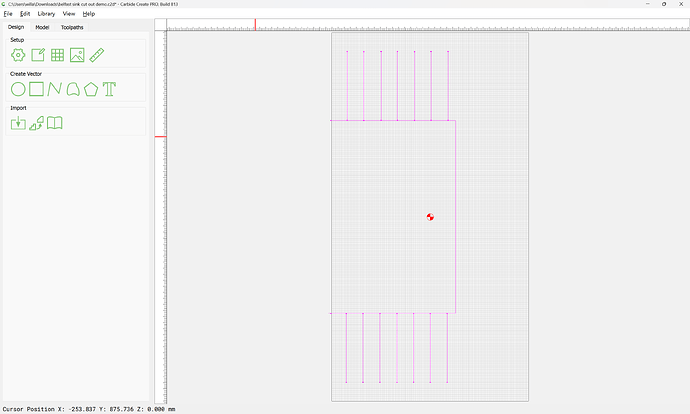

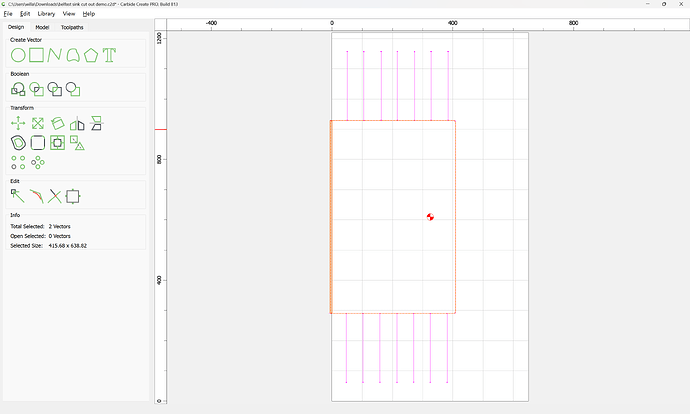

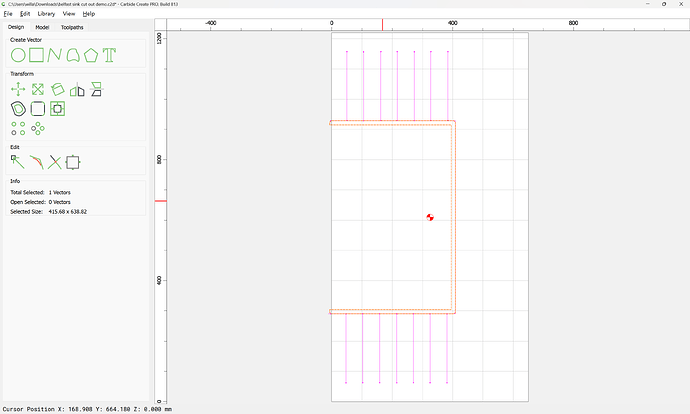

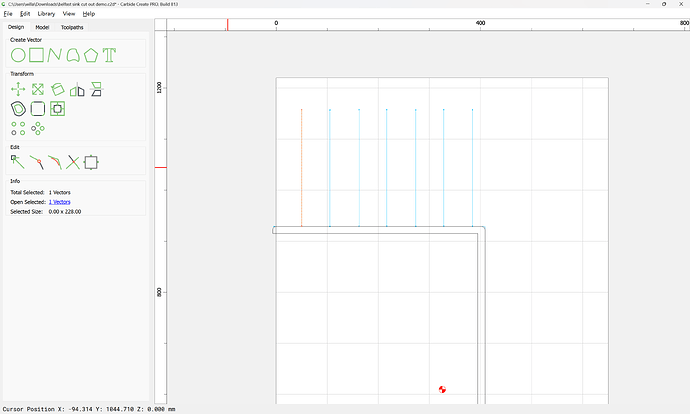

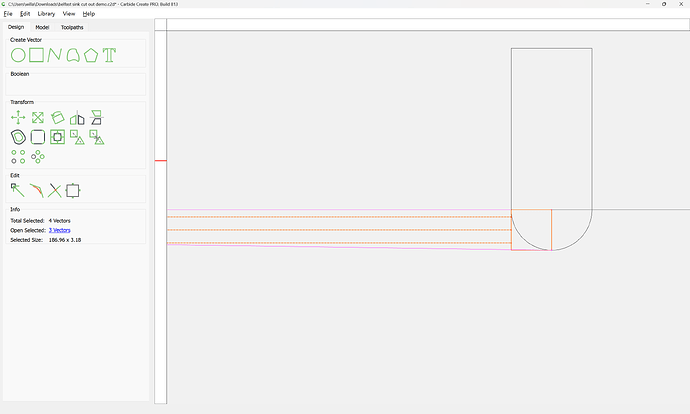

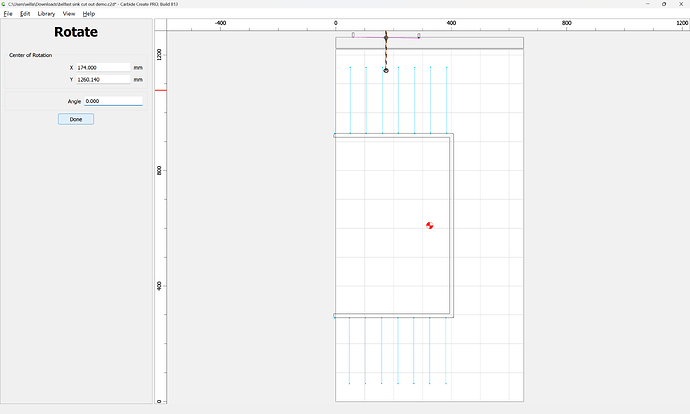

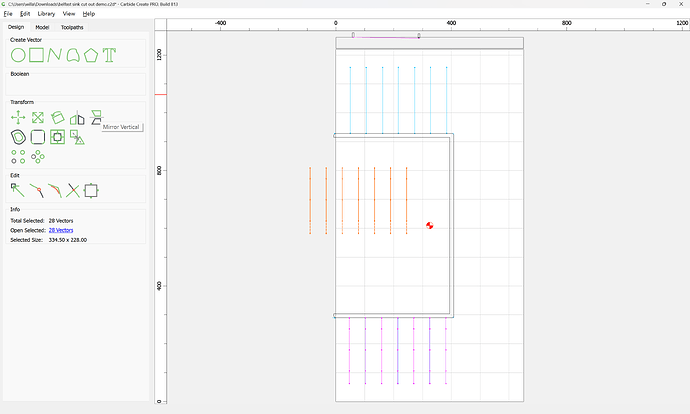

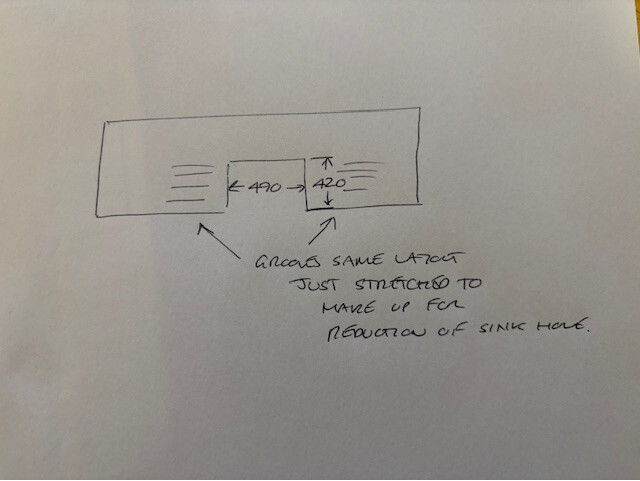

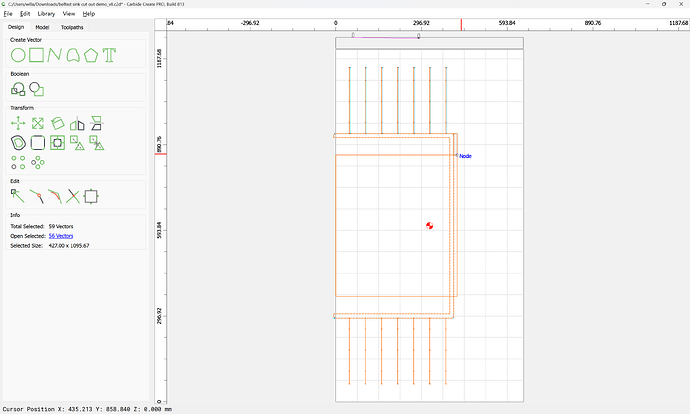

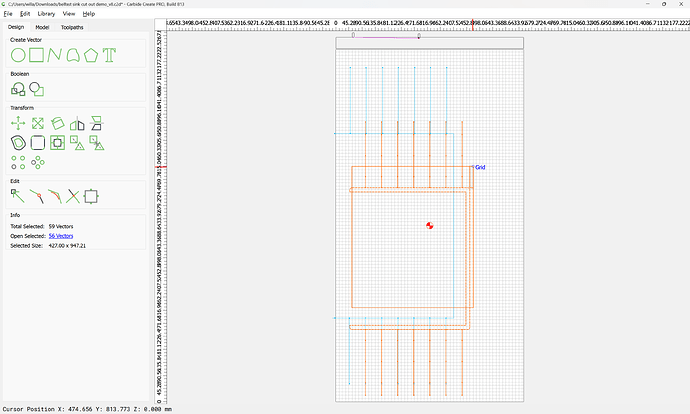

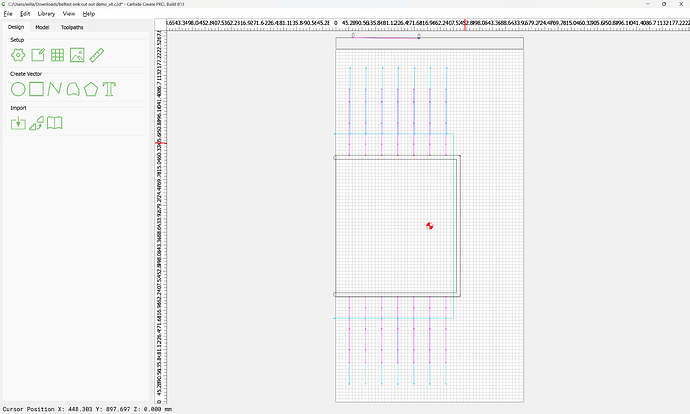

Given a rough sketch:

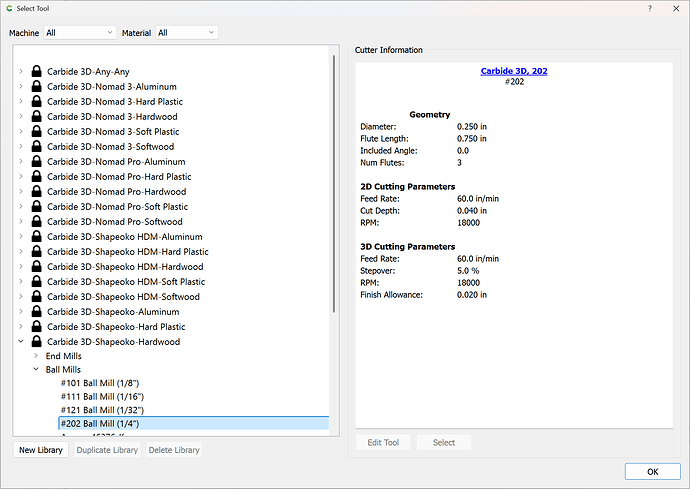

The goal is to make grooves using a 1/4" ball-nose (vertical lines), and a cutout for a farmer-style sink (the rectangle missing the left side)

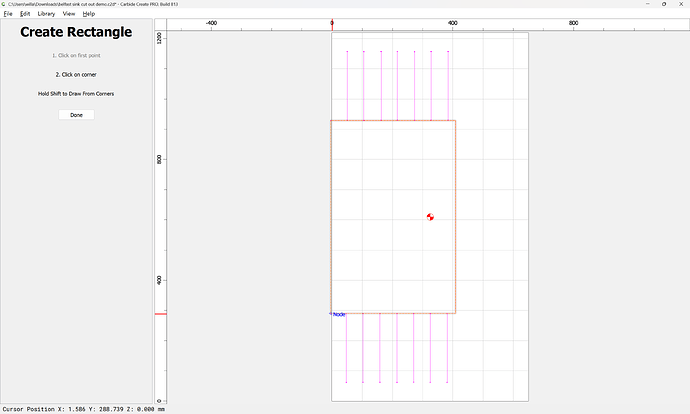

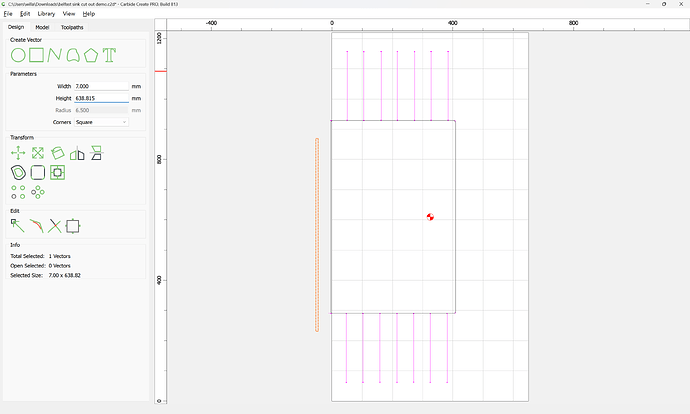

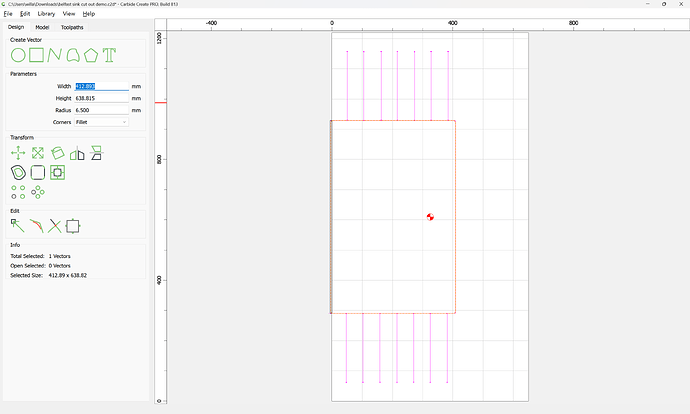

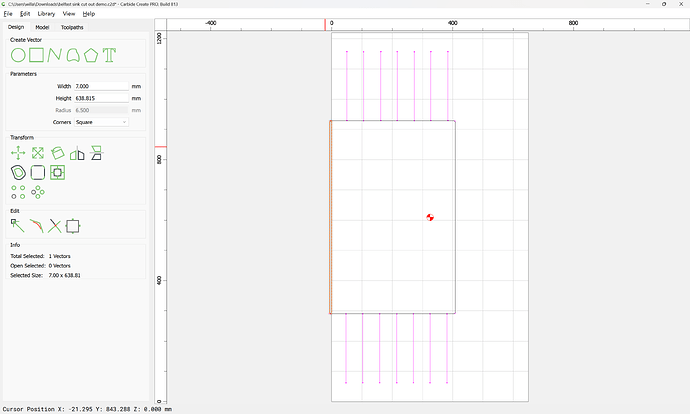

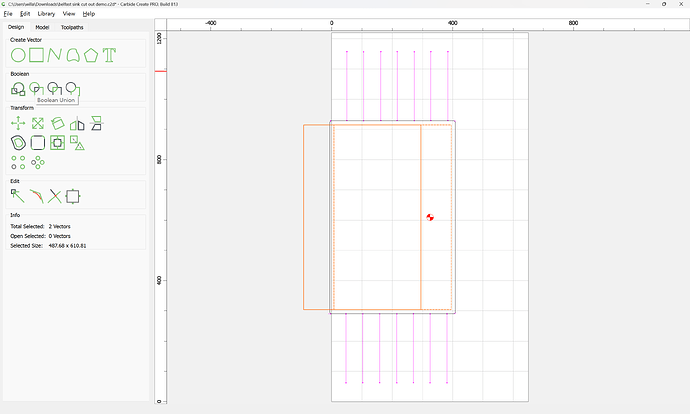

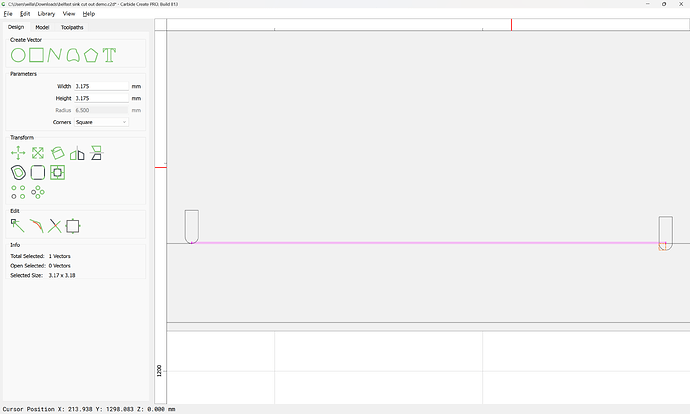

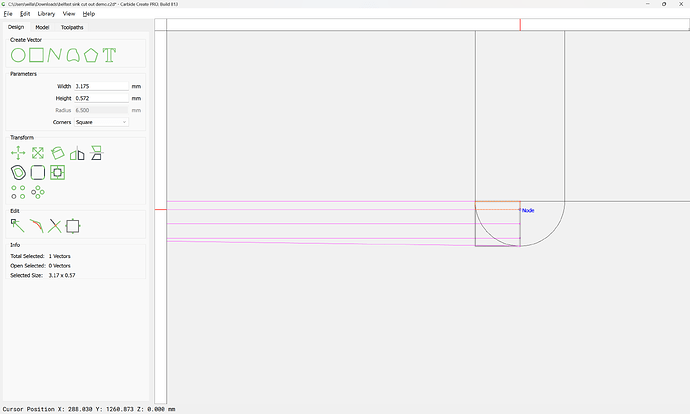

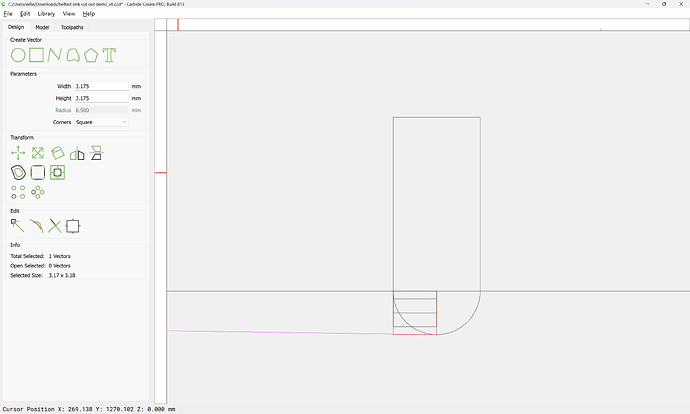

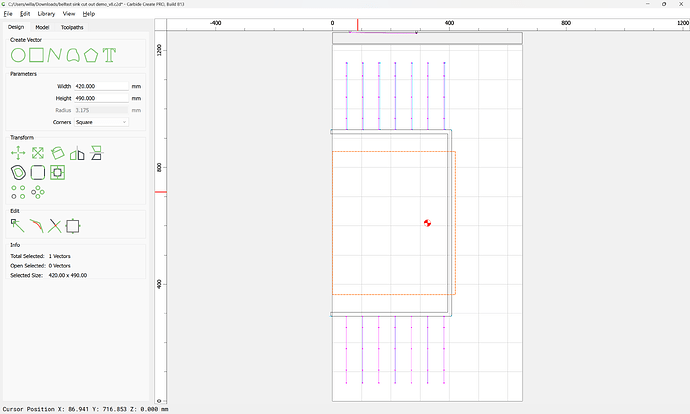

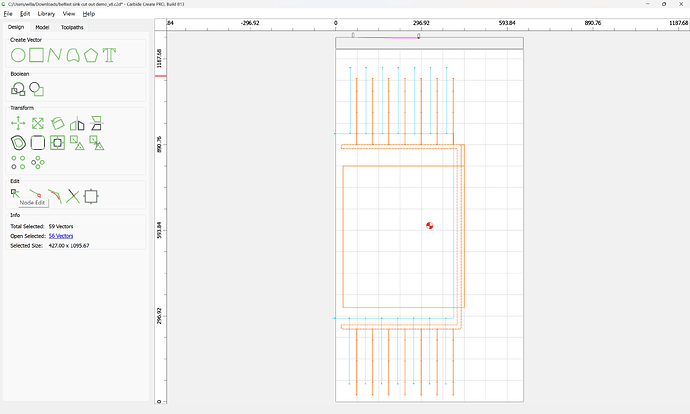

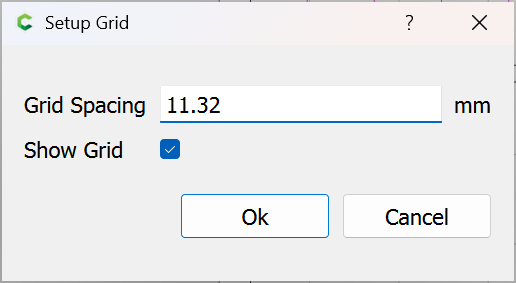

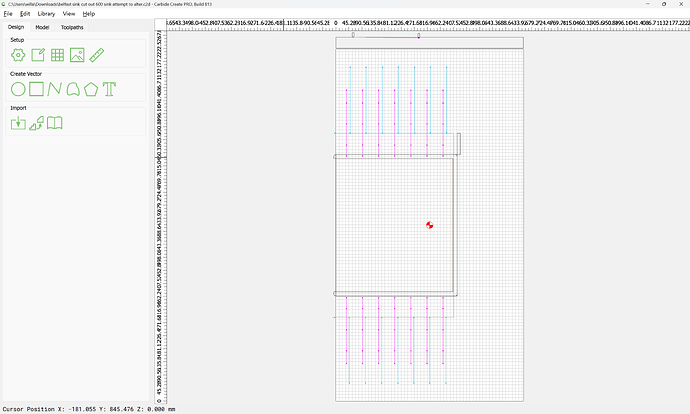

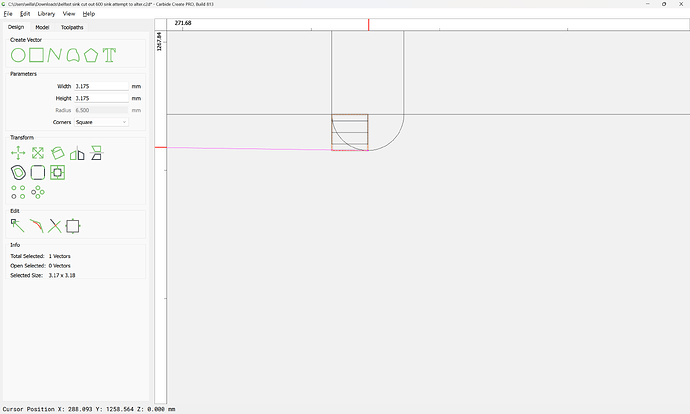

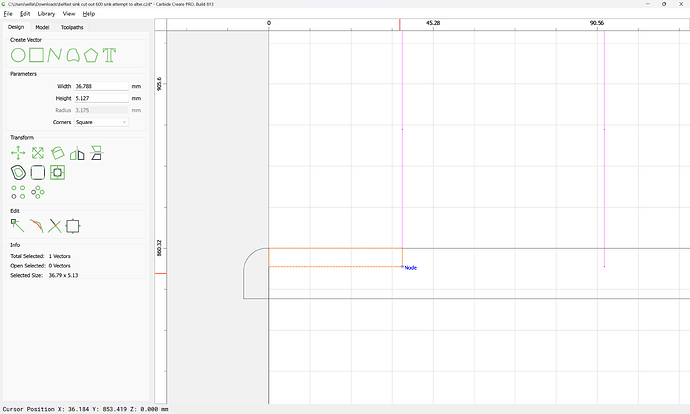

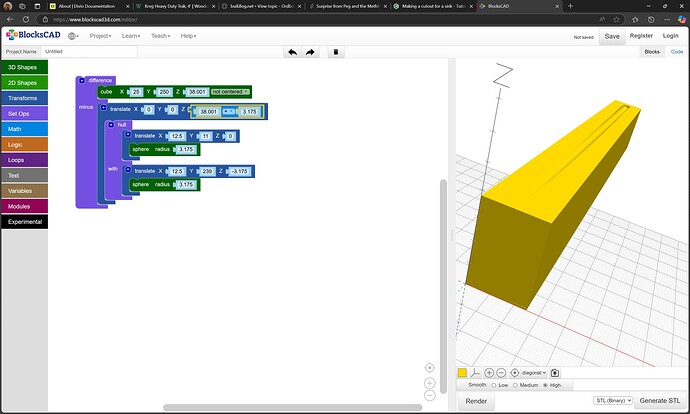

Since the cutout is easiest, we do that first — begin by drawing a rectangle:

and adjusting it to have a radius greater than the 1/2" diameter tool envisioned for making this cut:

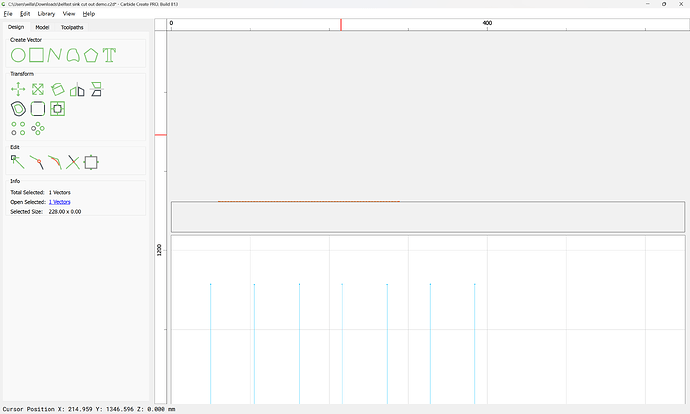

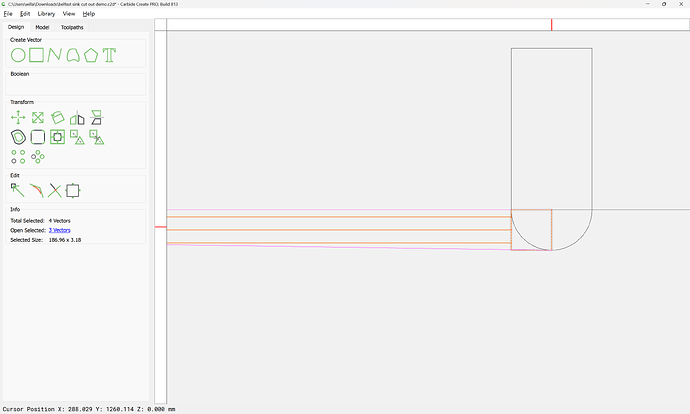

It is also necessary to ensure that it projects by a bit more than tool radius beyond the stock origin to the left:

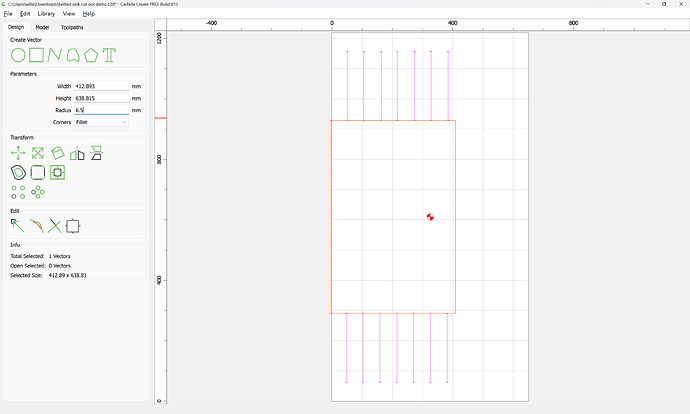

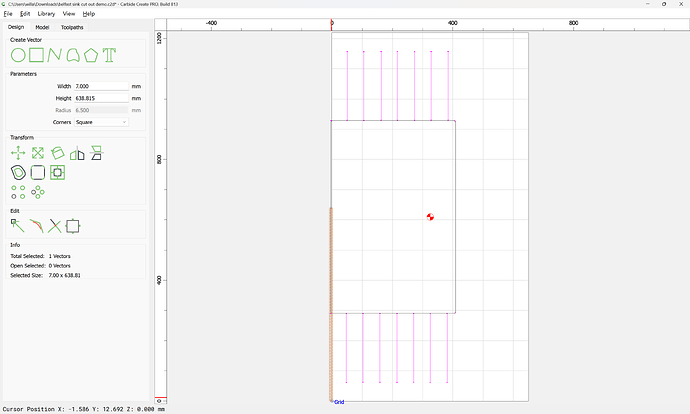

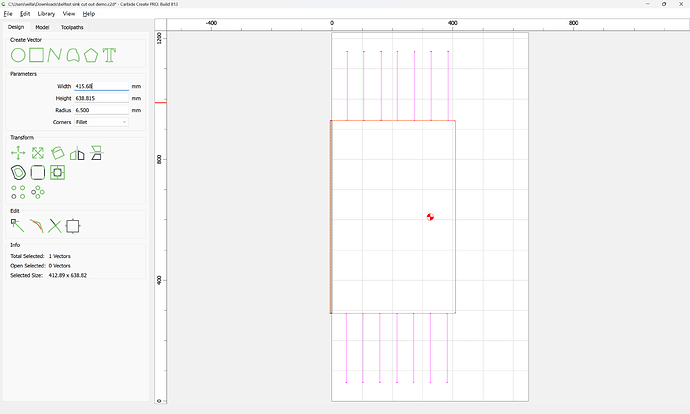

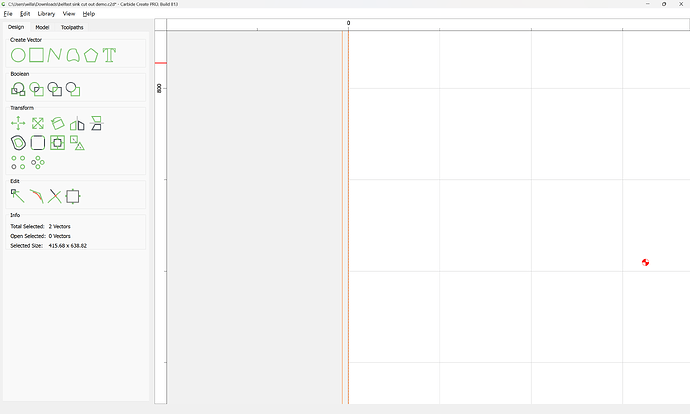

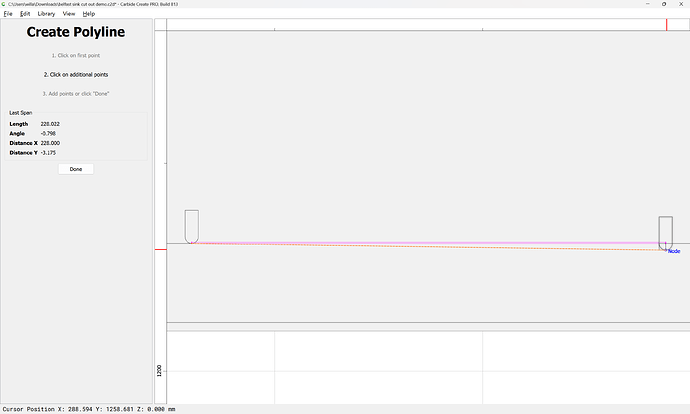

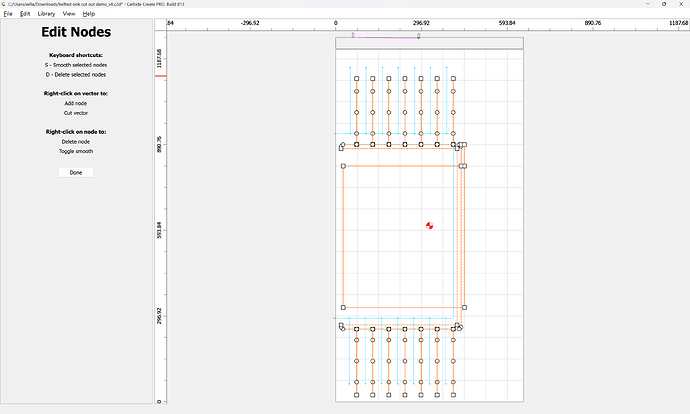

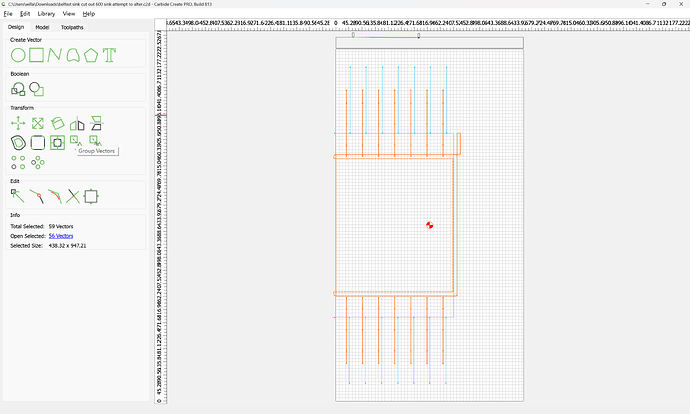

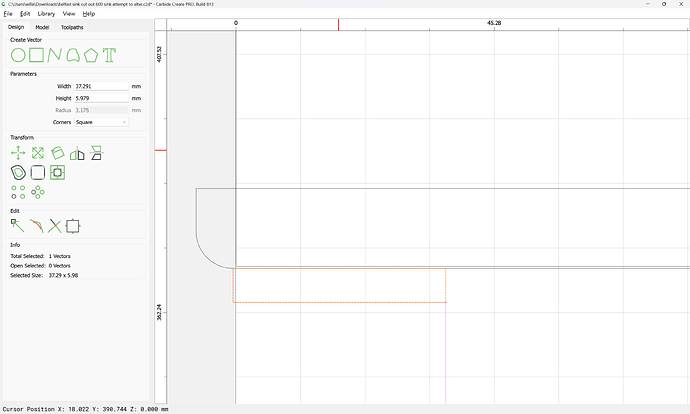

Note the width dimension for the selection, 415.68:

and change the original rectangle to that width:

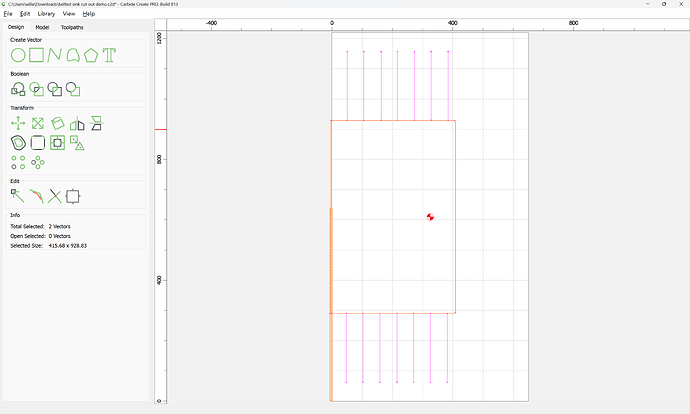

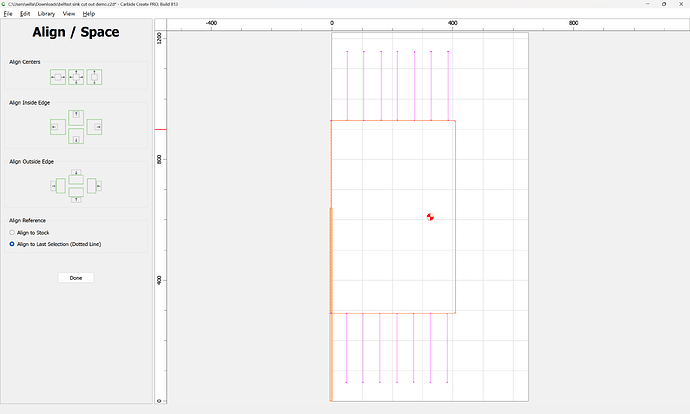

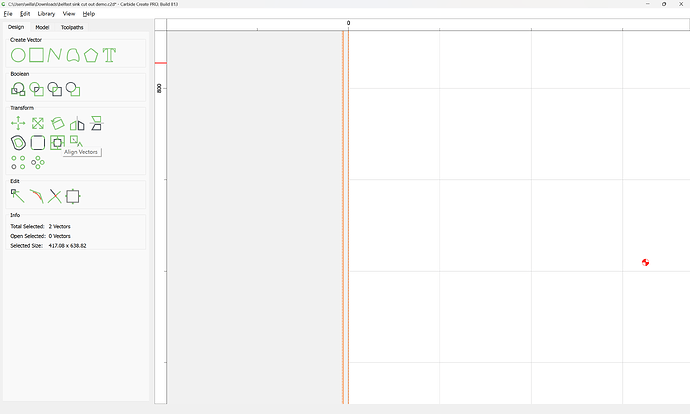

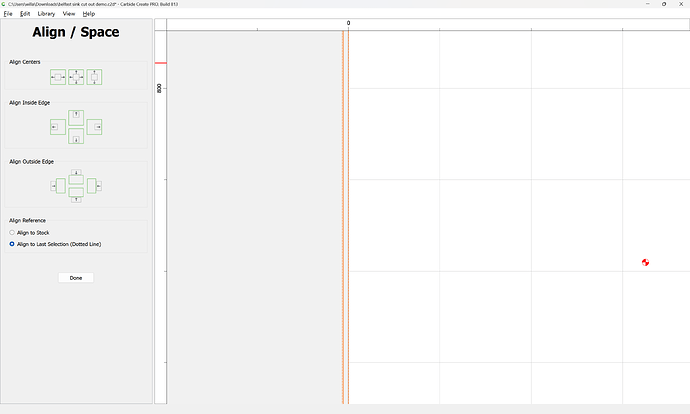

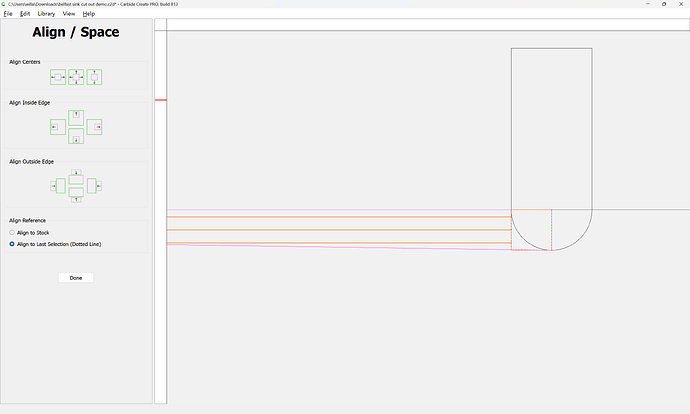

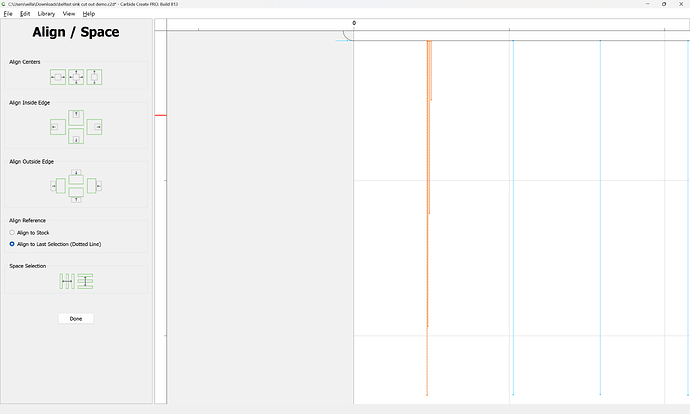

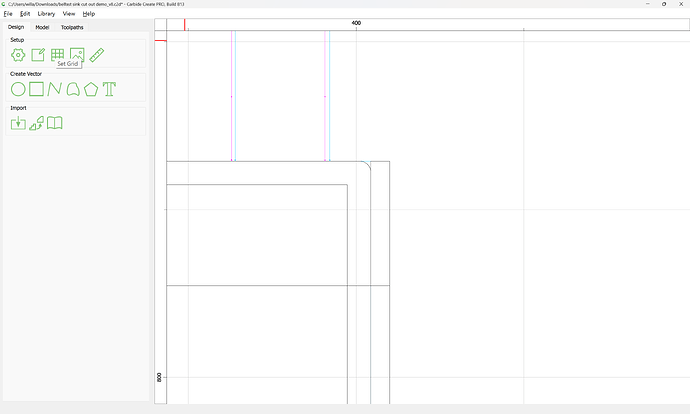

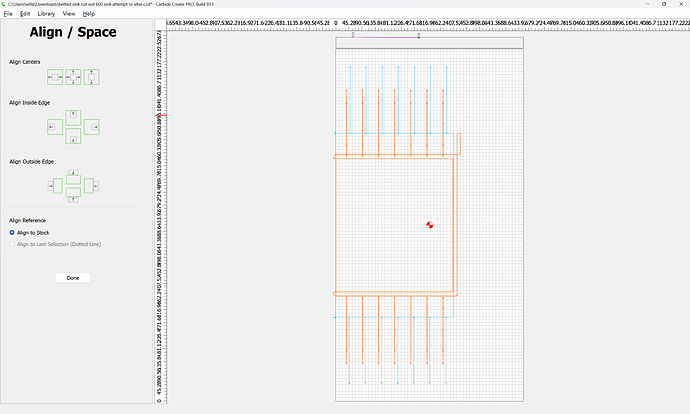

and then align it against the narrow one used to set the radius:

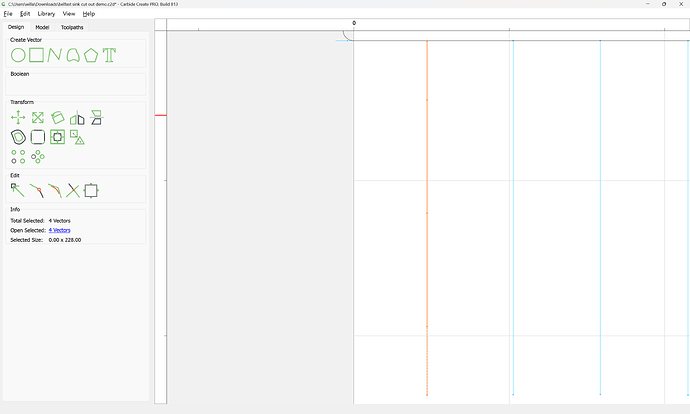

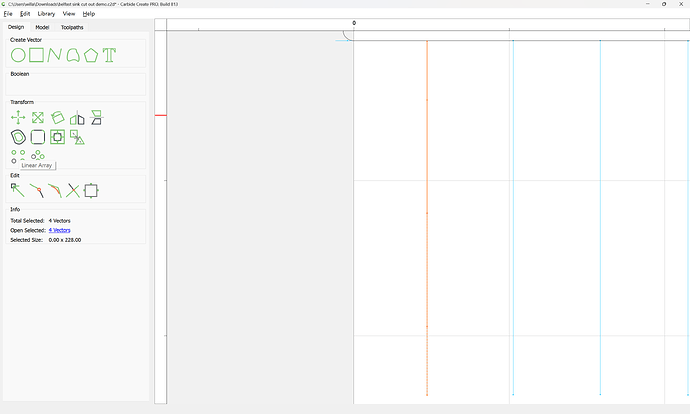

which may now be deleted:

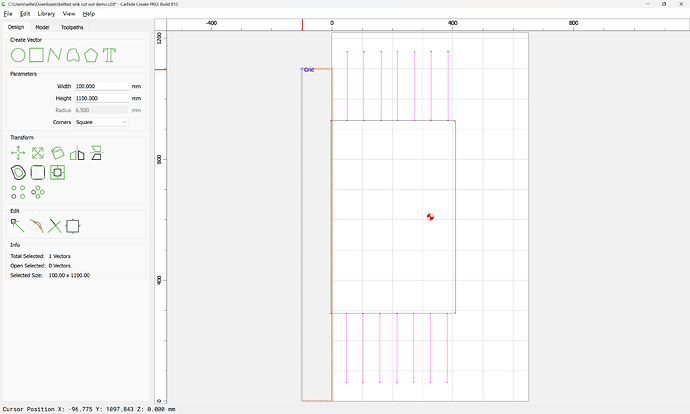

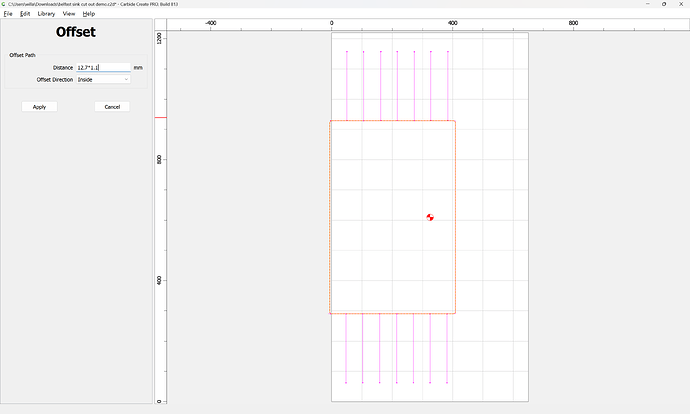

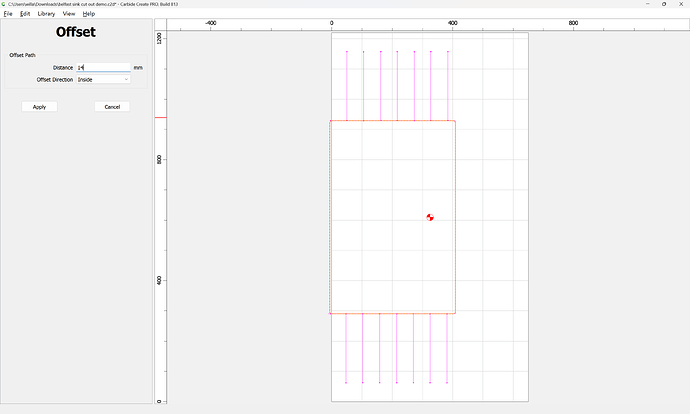

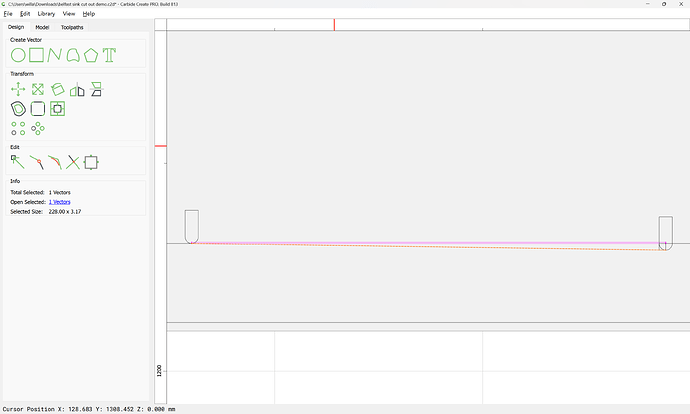

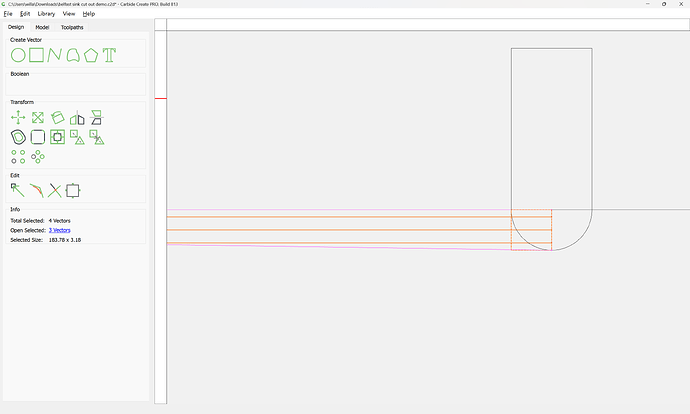

Inset the rectangle by tool diameter plus 10% or so:

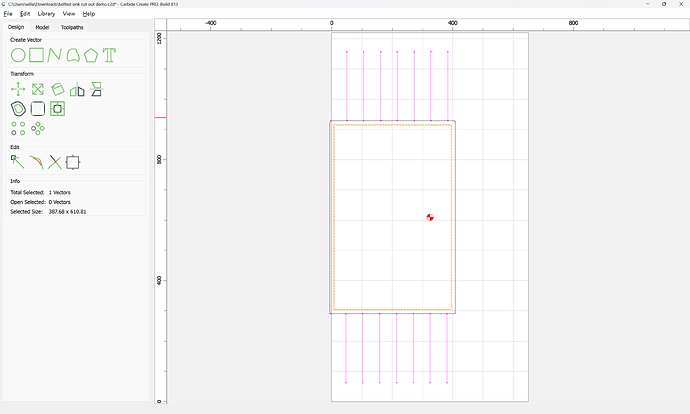

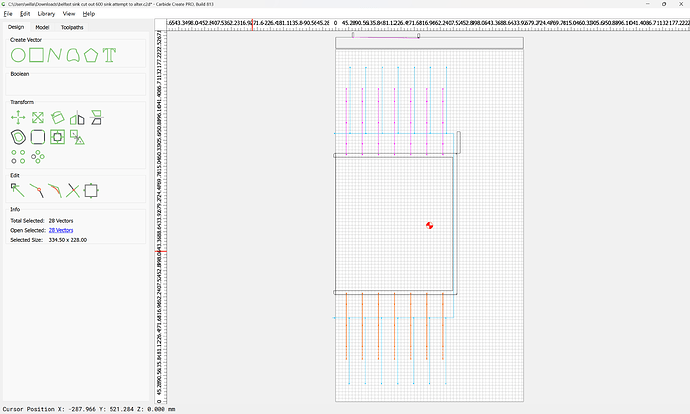

Duplicate the resultant geometry and move it to the left:

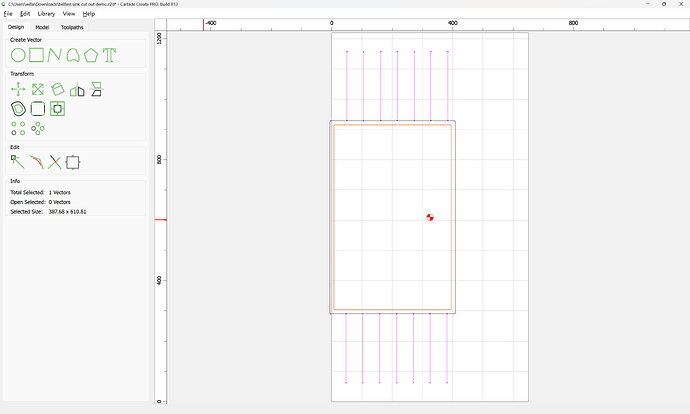

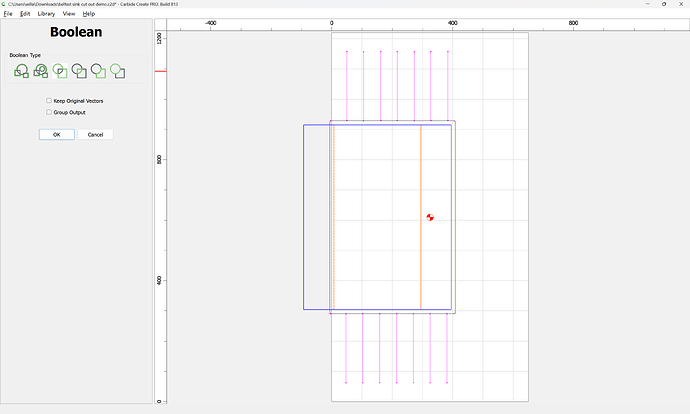

and then union it with the inset in the original position:

OK

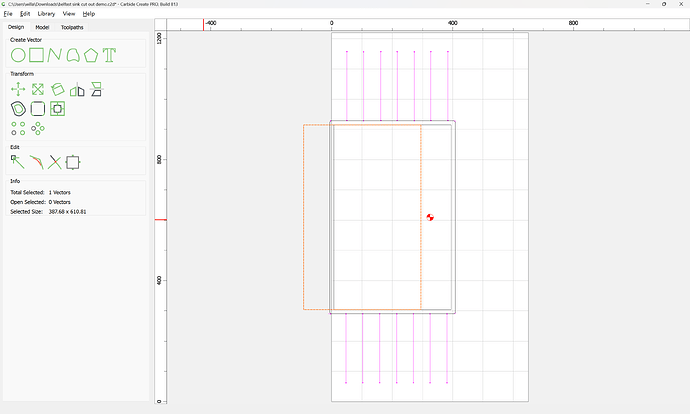

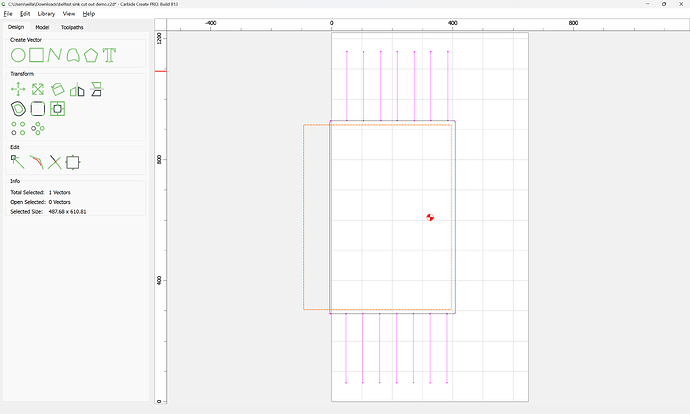

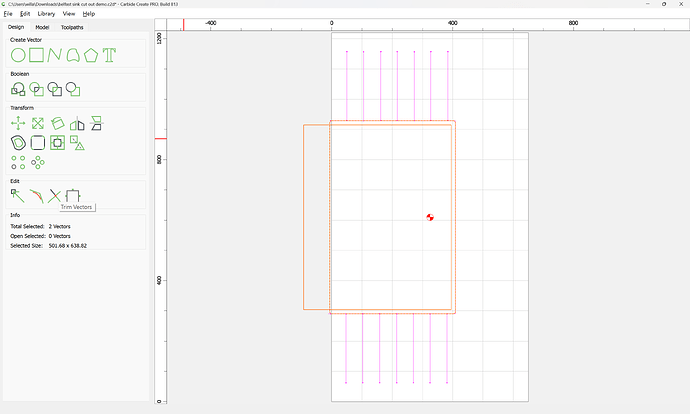

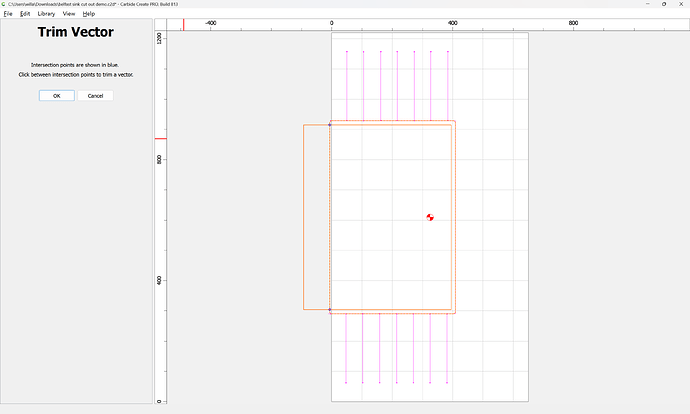

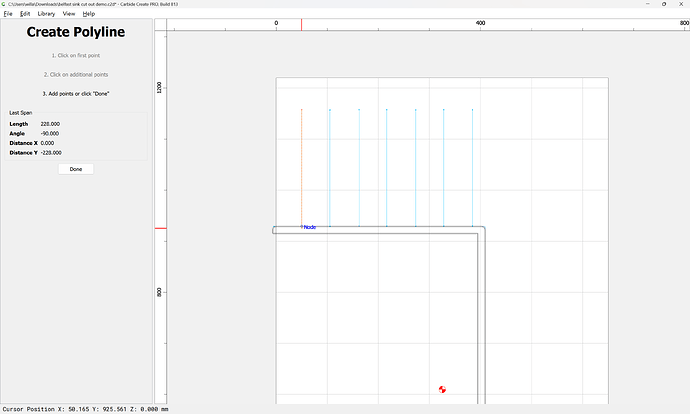

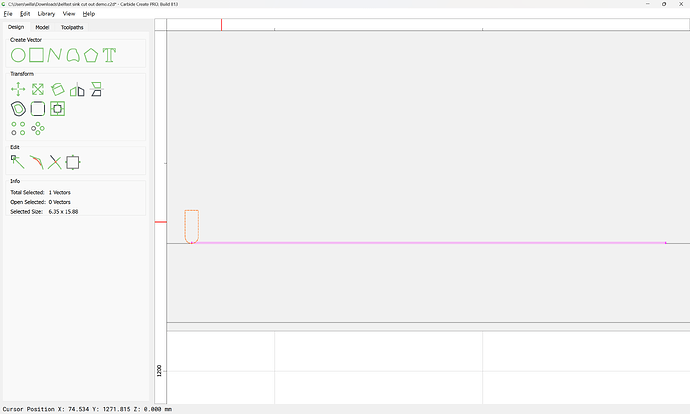

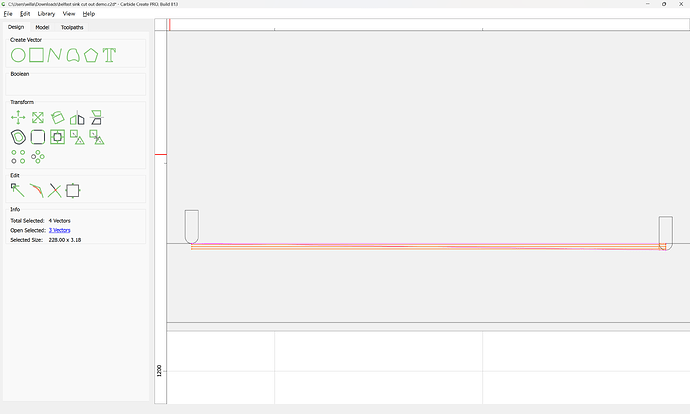

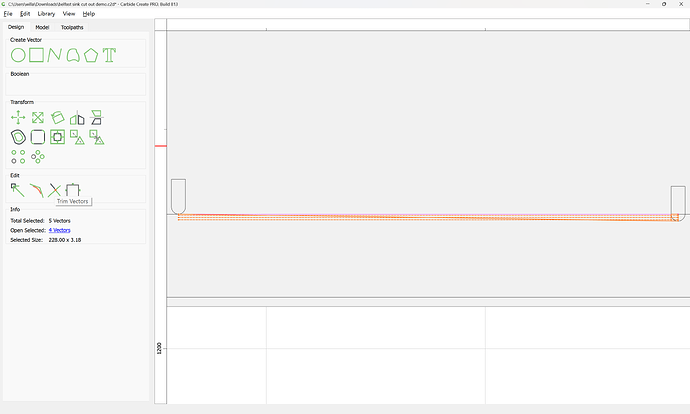

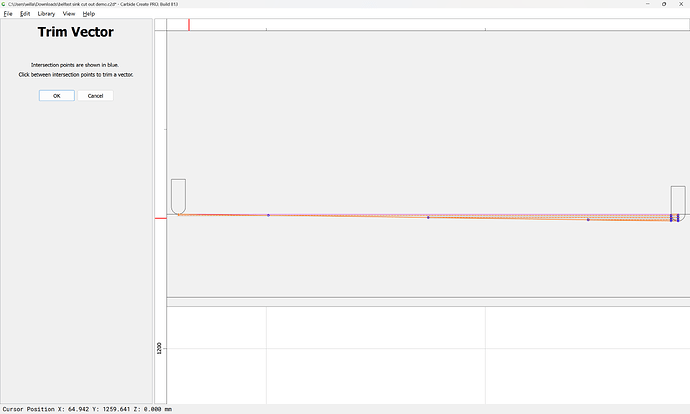

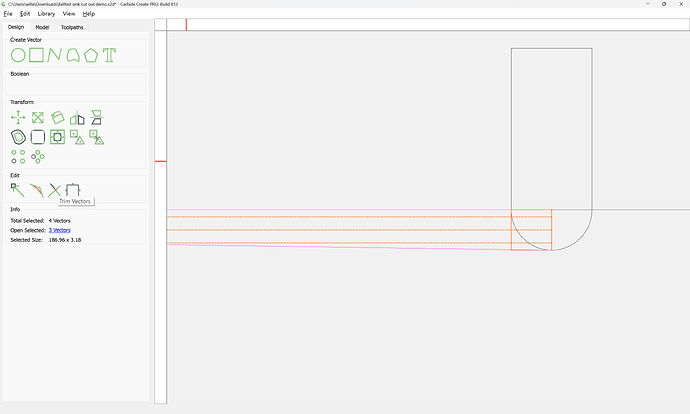

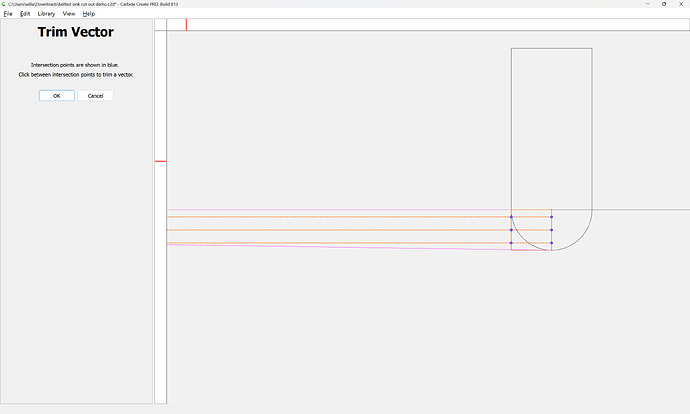

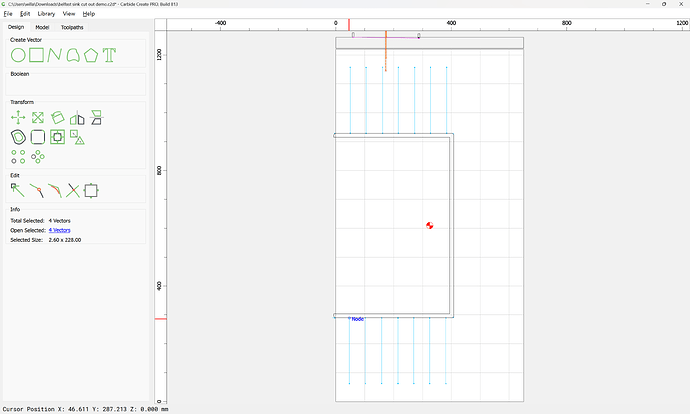

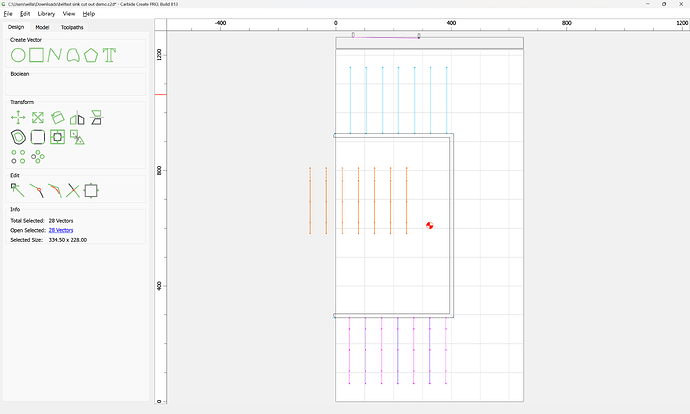

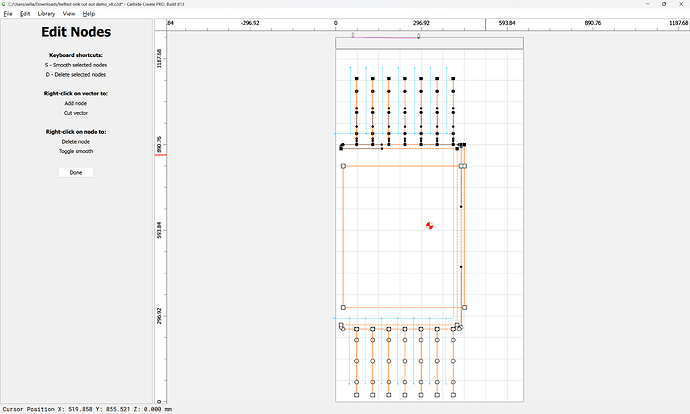

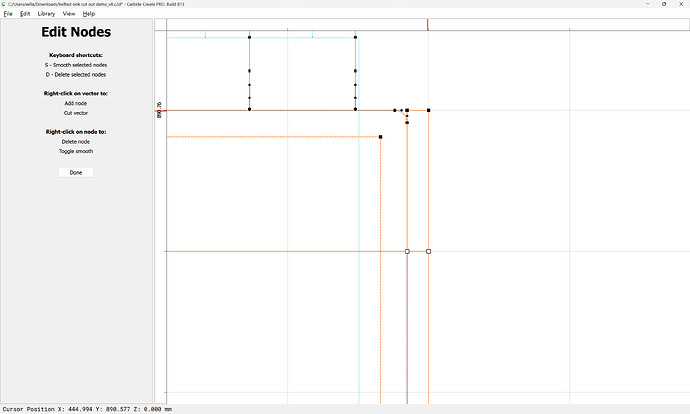

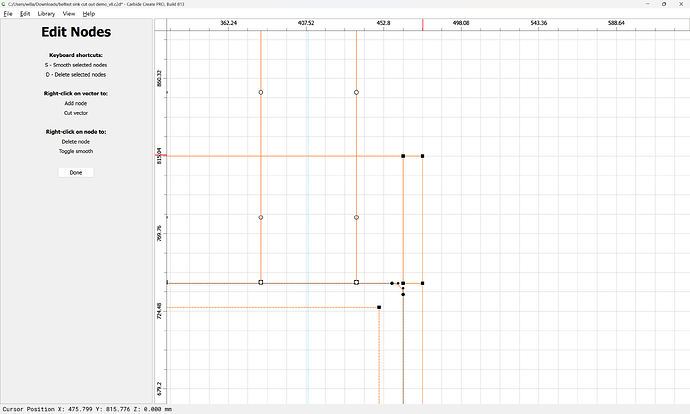

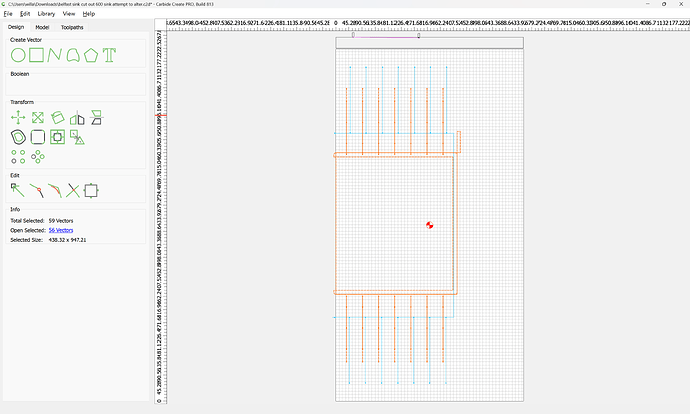

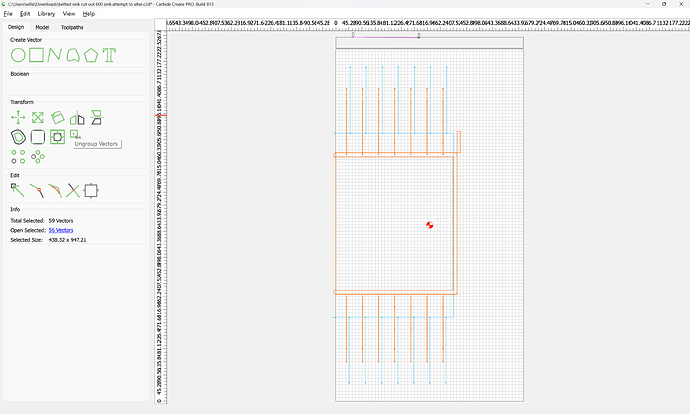

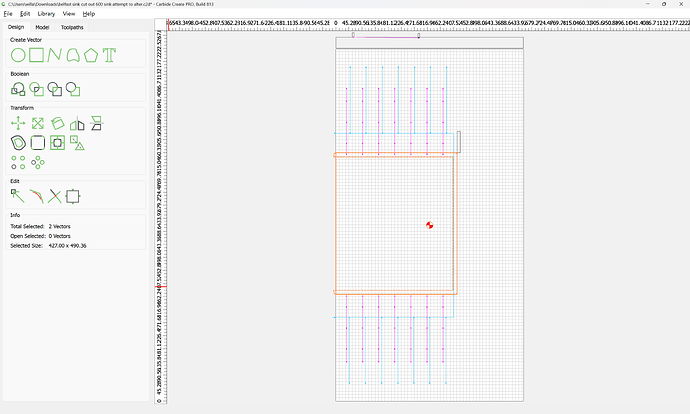

Select both rectangles and use Trim Vectors:

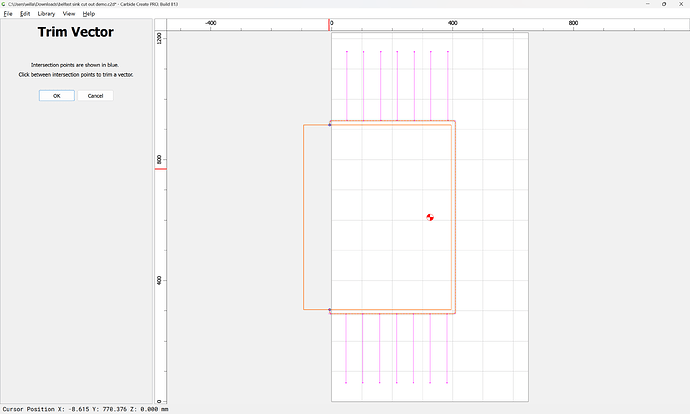

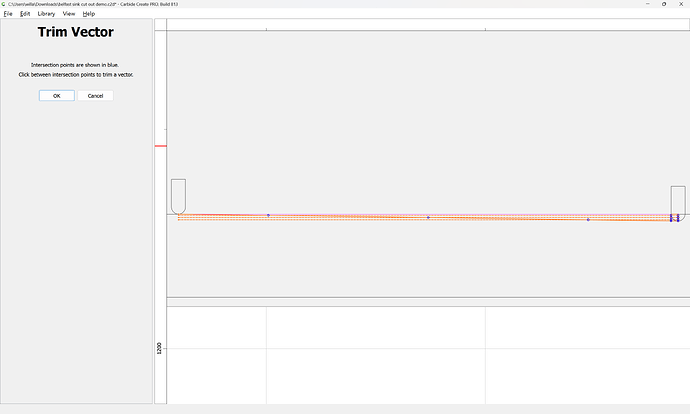

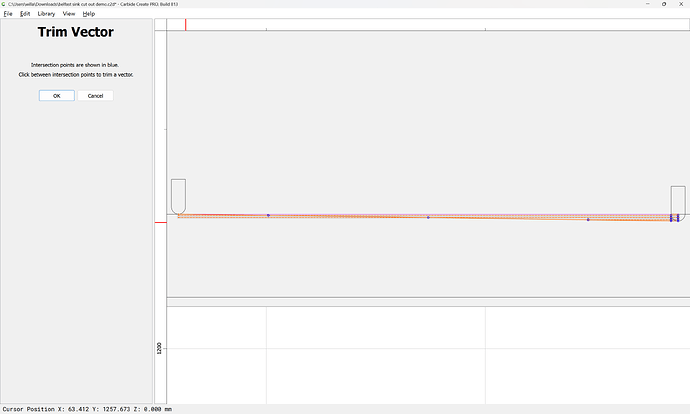

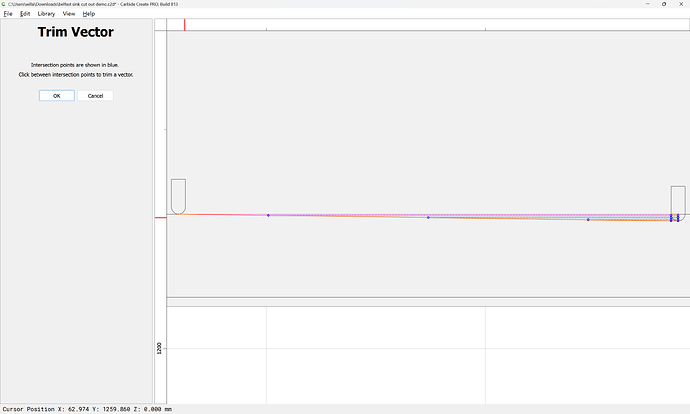

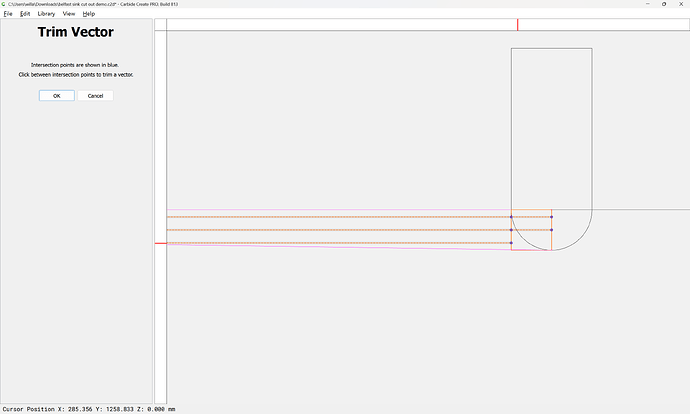

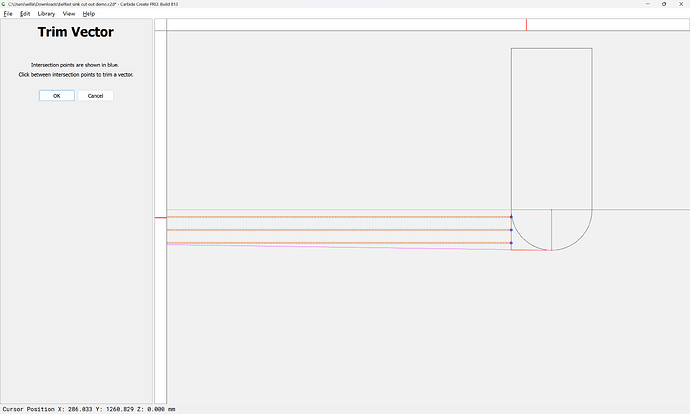

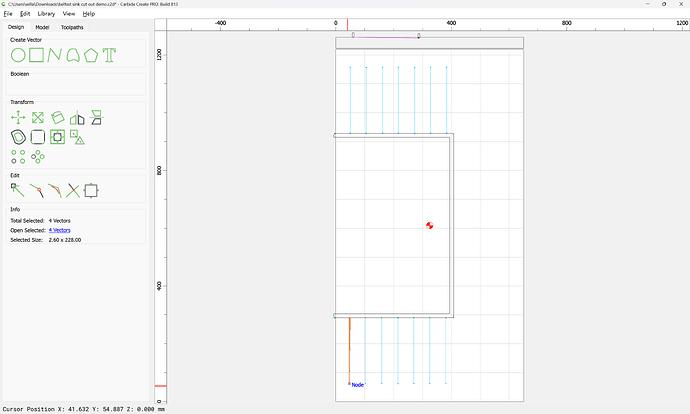

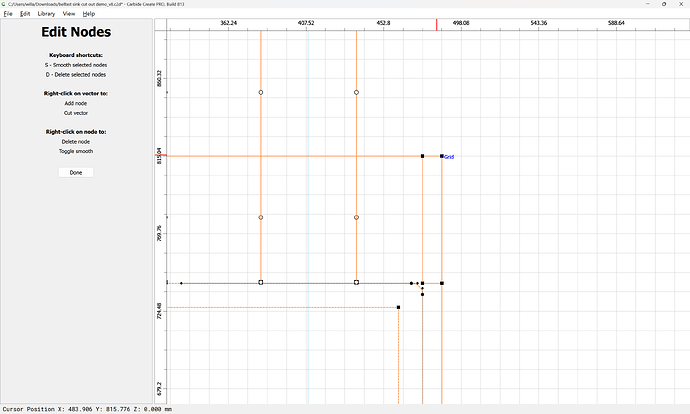

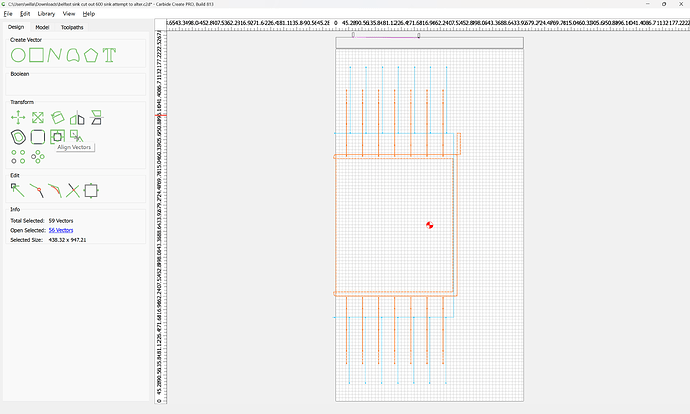

to remove what is not wanted:

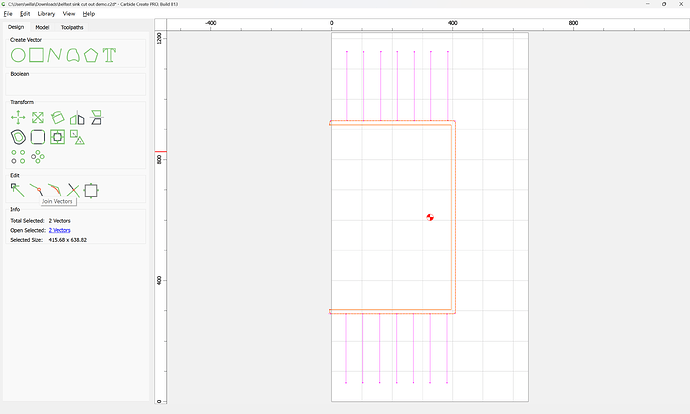

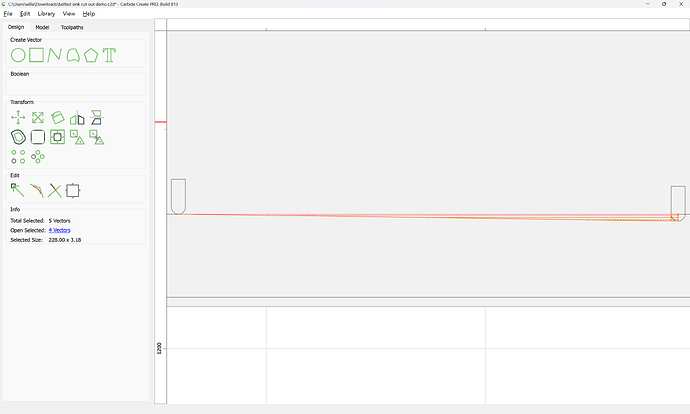

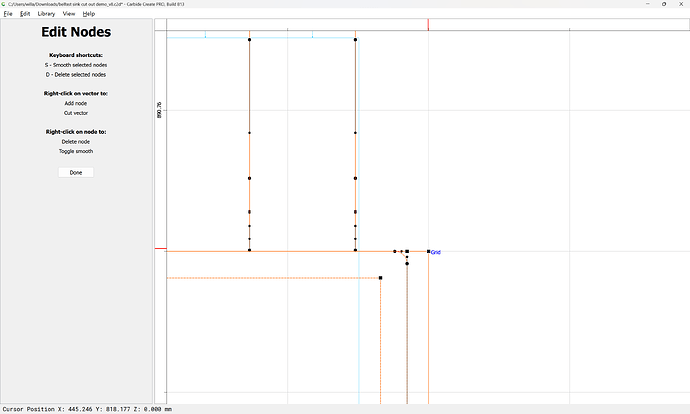

arriving at:

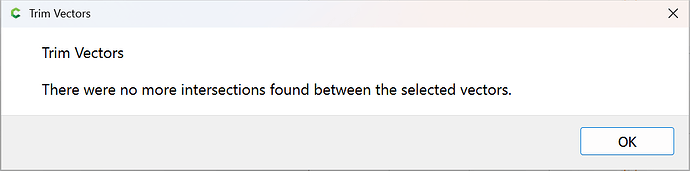

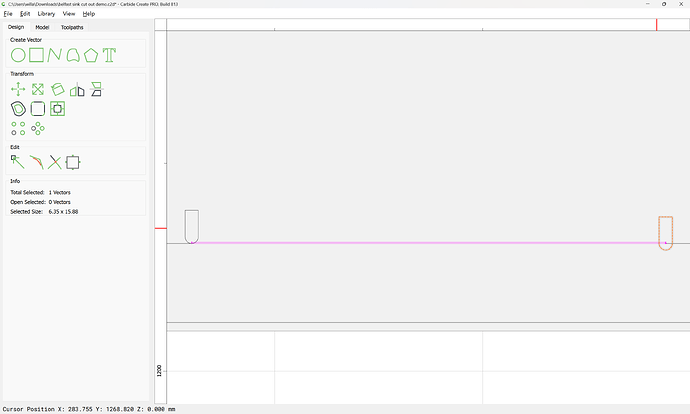

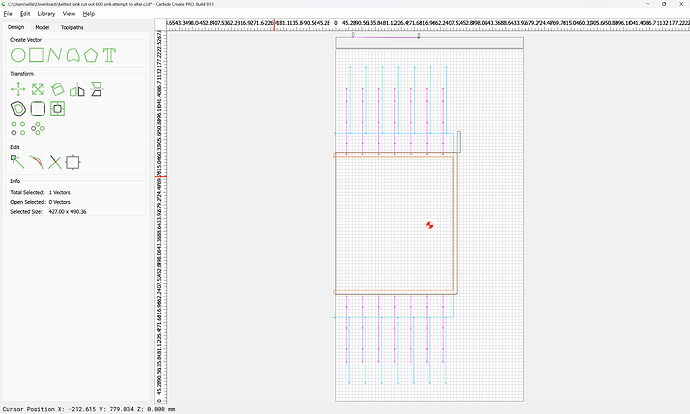

OK

Join Vectors

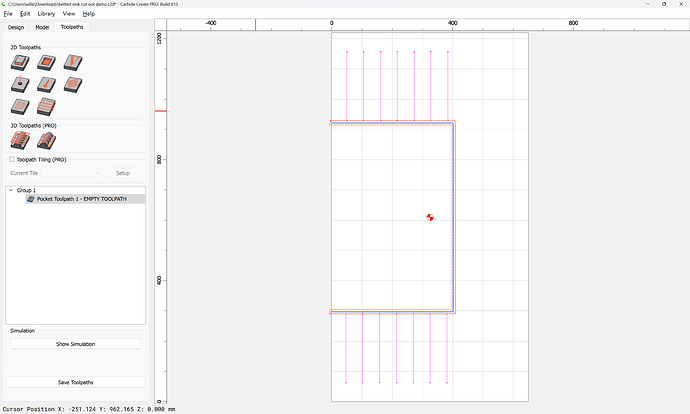

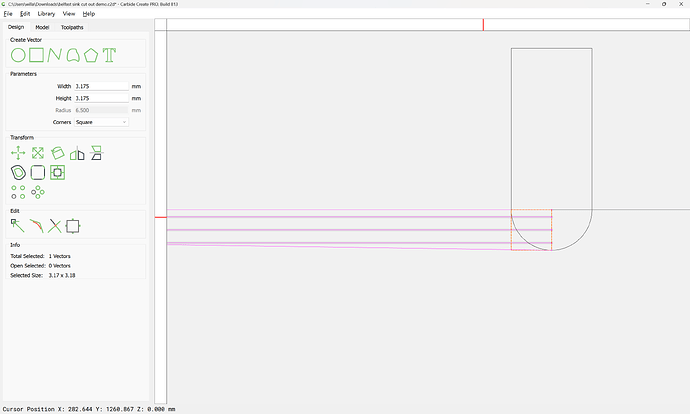

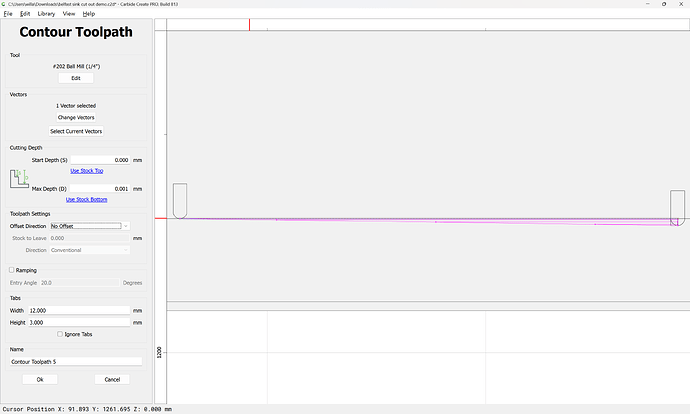

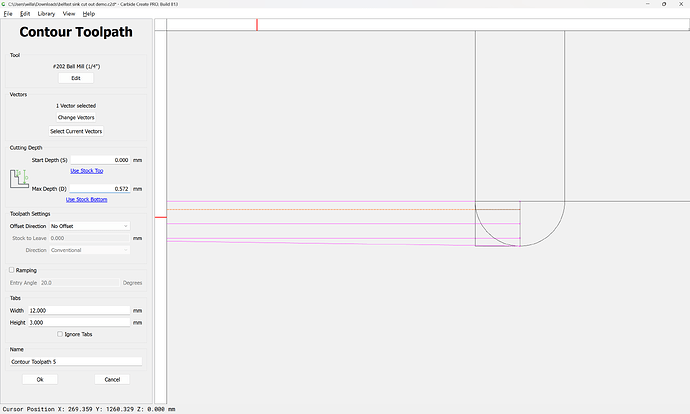

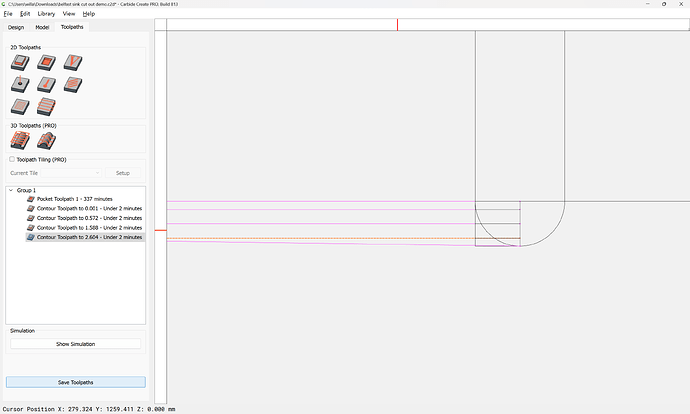

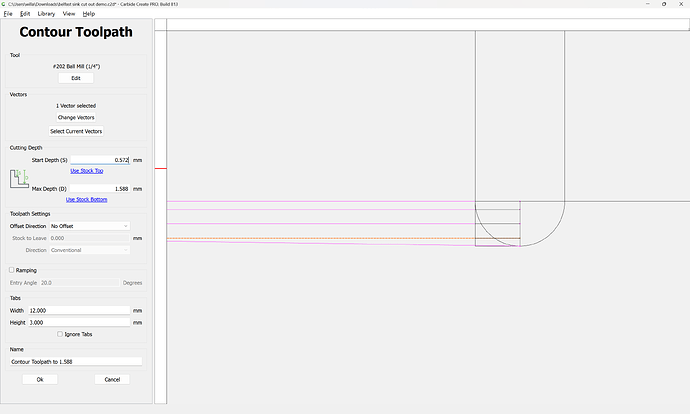

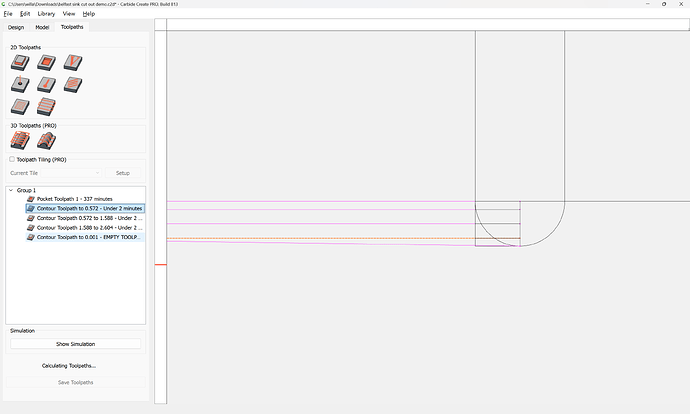

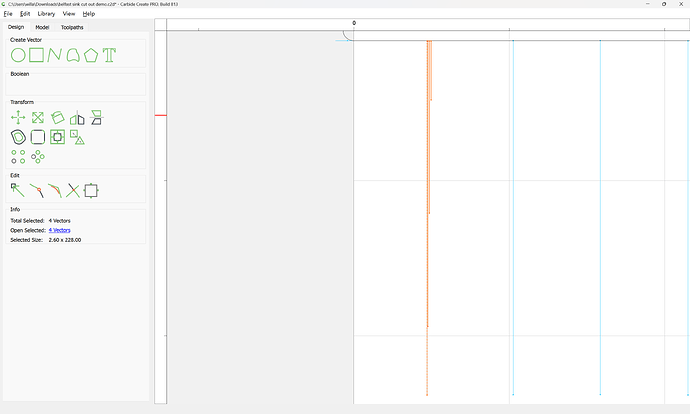

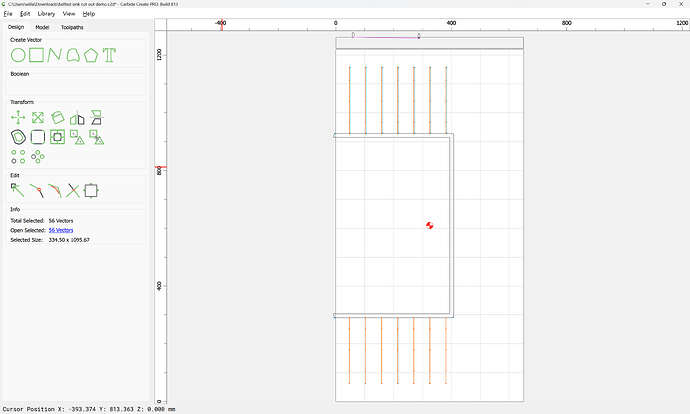

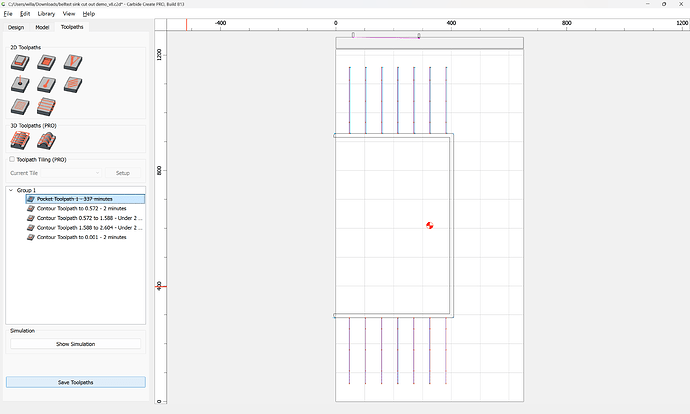

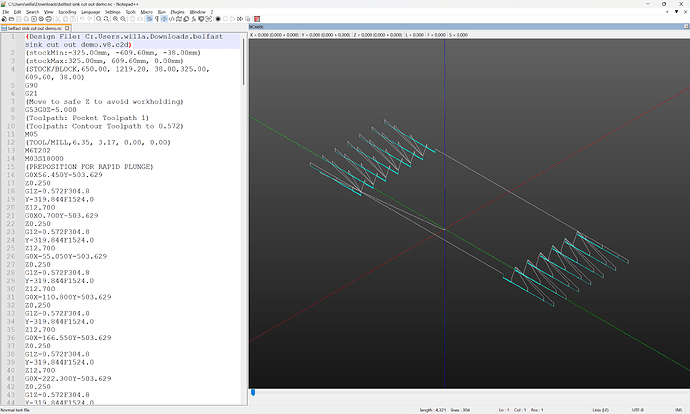

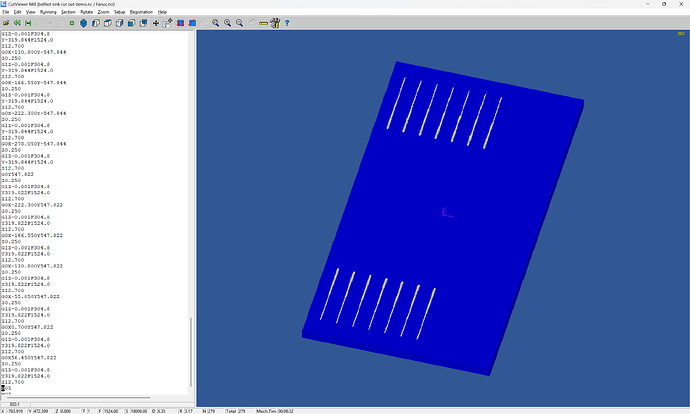

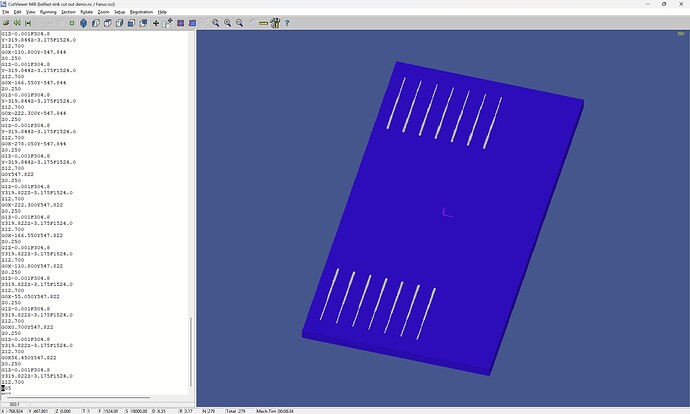

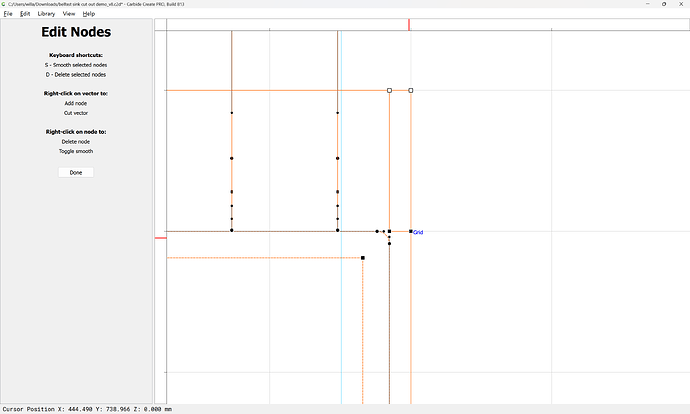

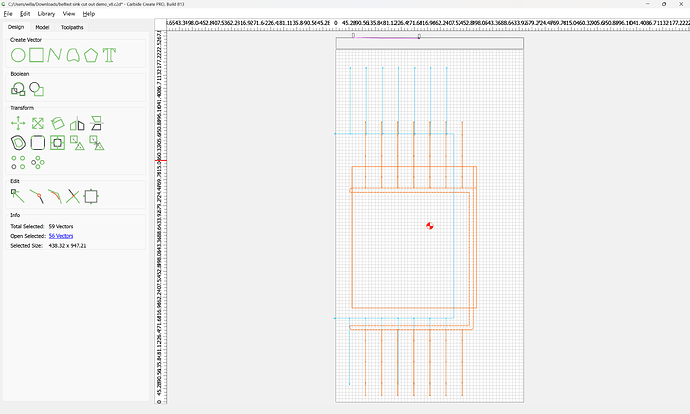

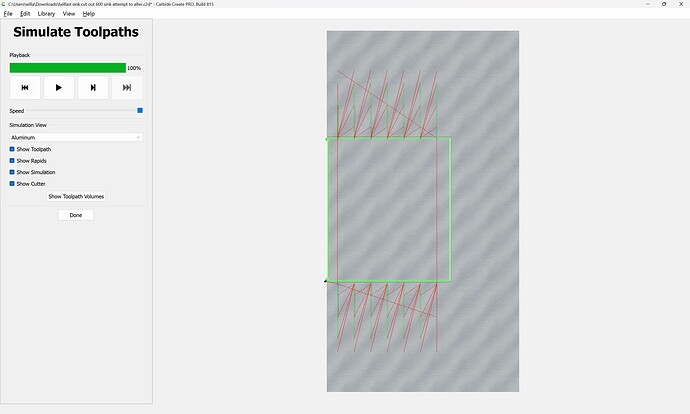

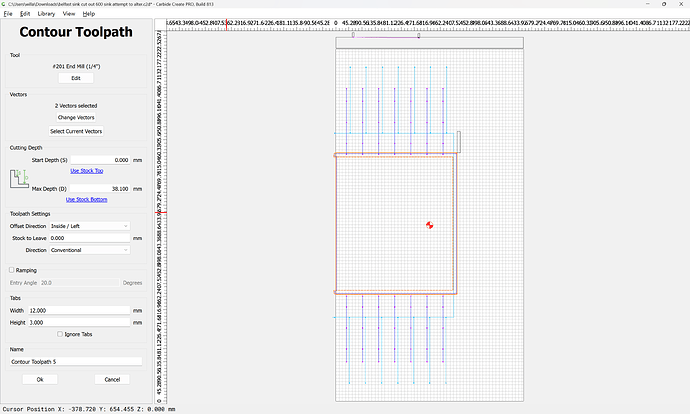

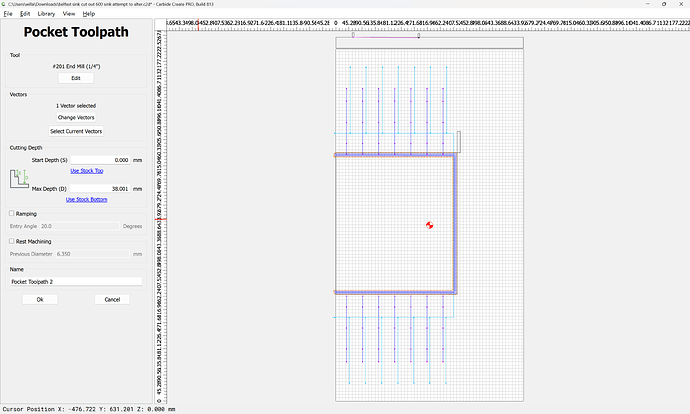

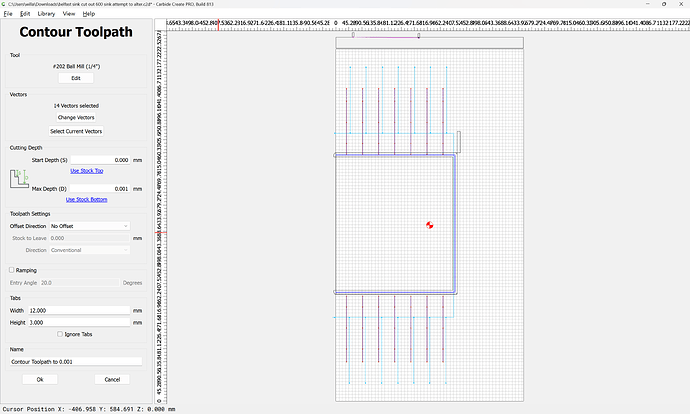

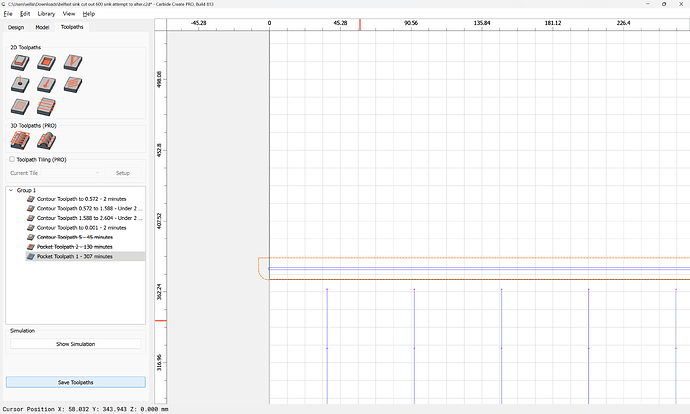

At this point a pocket toolpath w/ a suitable tool may be assigned to make the opening cut:

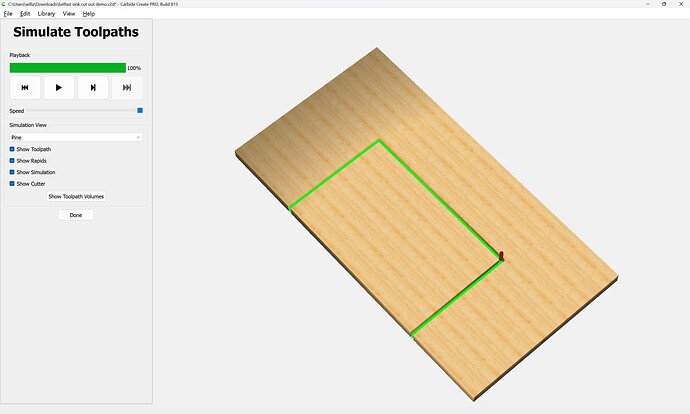

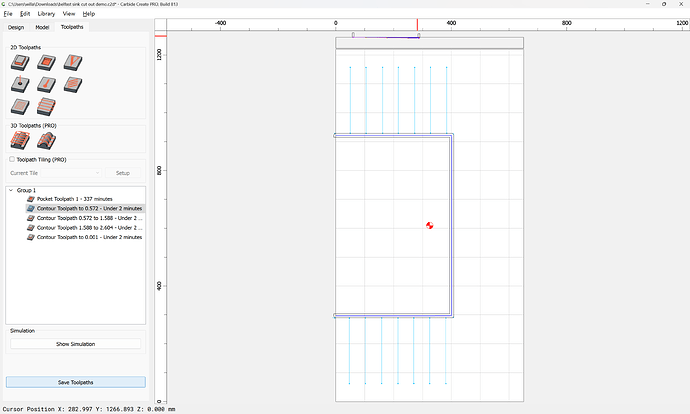

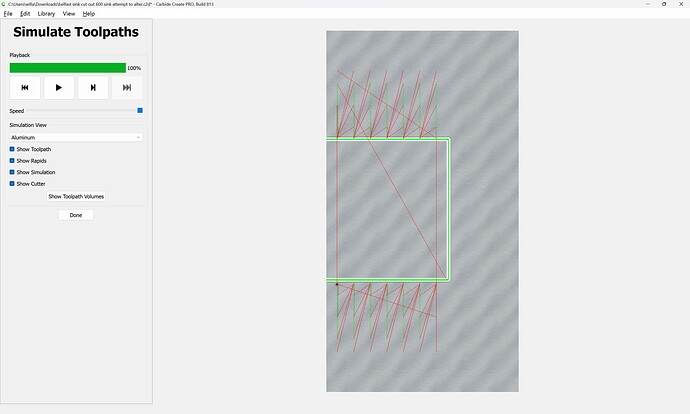

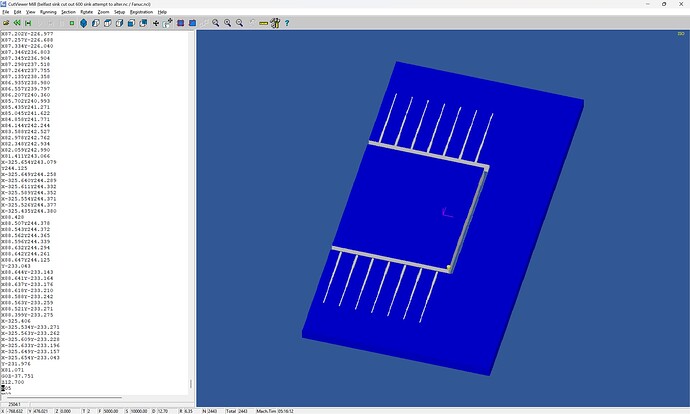

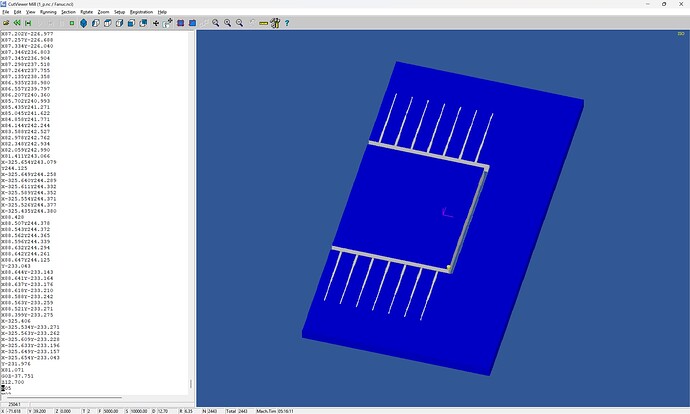

which previews as:

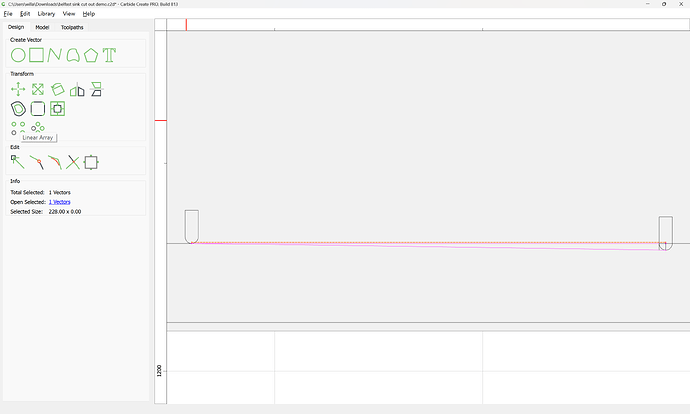

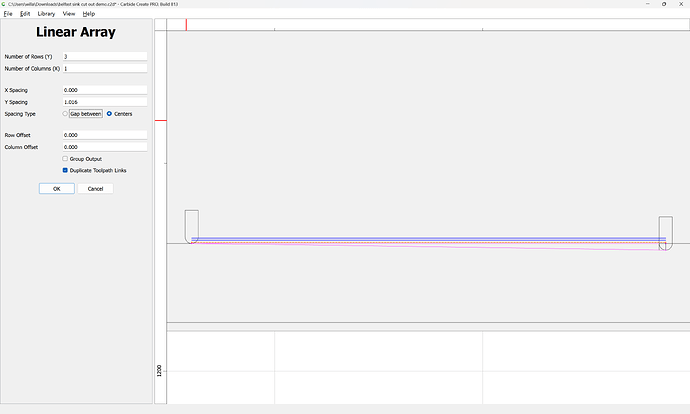

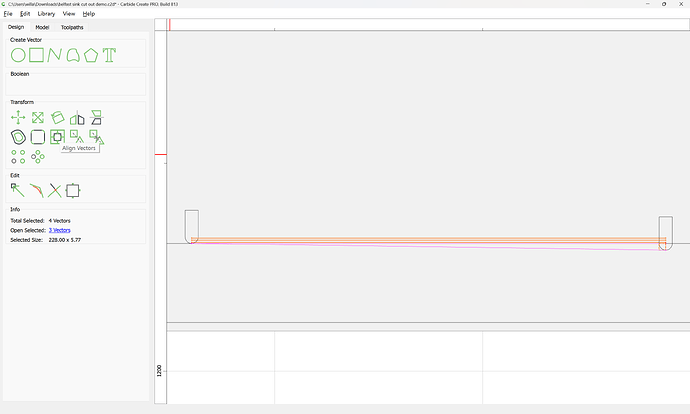

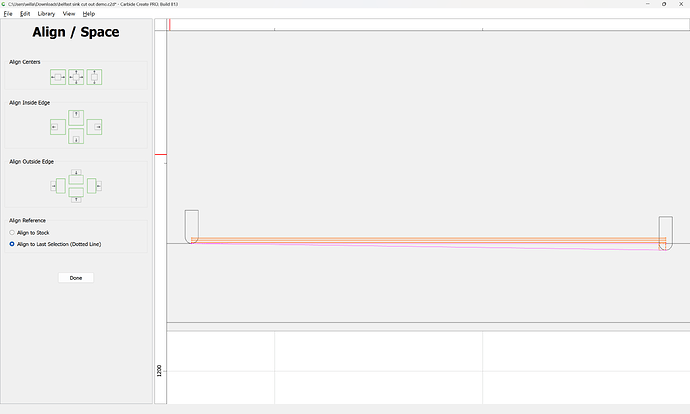

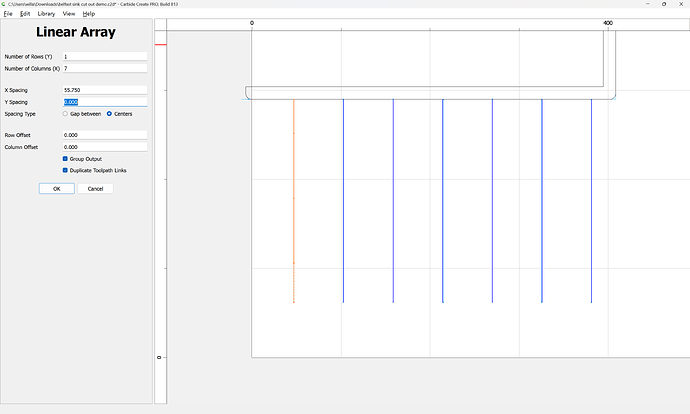

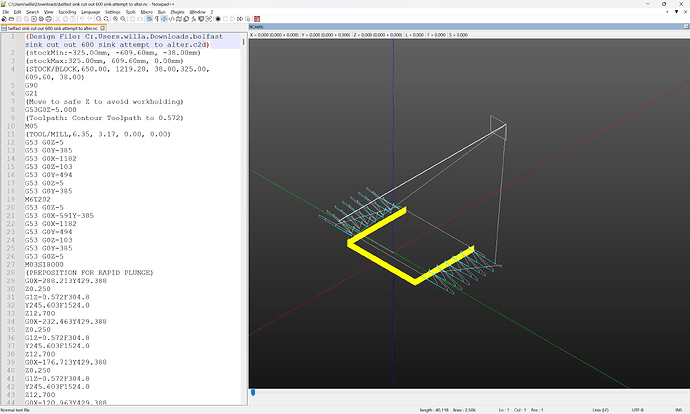

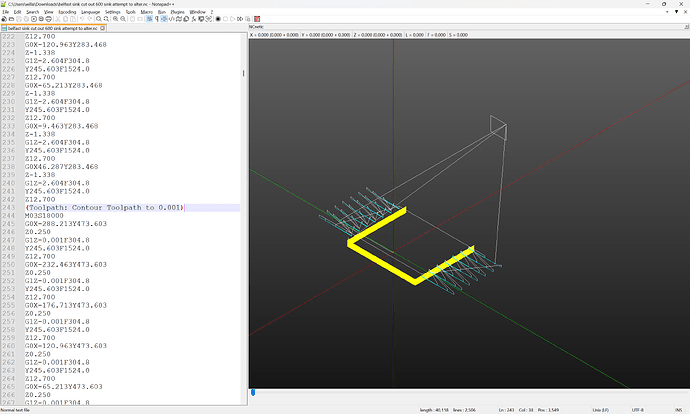

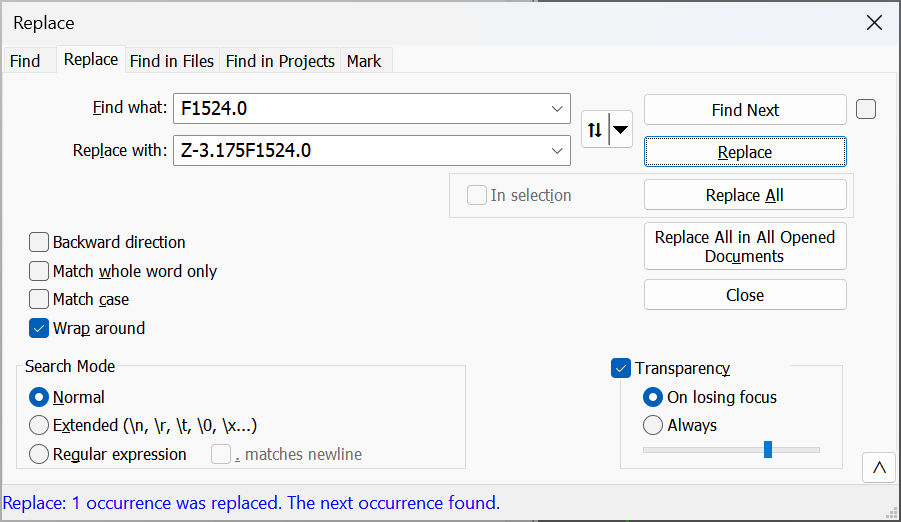

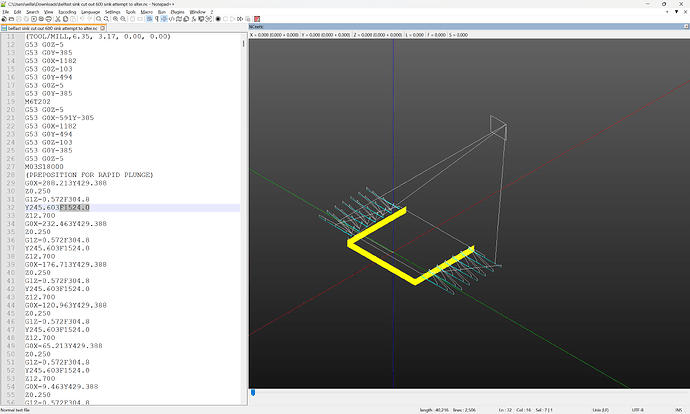

Next, for the grooves, this will be done as a series of short straight lines for the initial cut, then a finishing pass will be made using hand-edited G-code.