Sharing this for others that may be interested:

In this video I cover several low cost performance upgrades to get more from your carbide3d nomad 883 cnc!

Enjoy!

Sharing this for others that may be interested:

In this video I cover several low cost performance upgrades to get more from your carbide3d nomad 883 cnc!

Enjoy!

Some great thoughts in there!

Excellent video with some very interesting and simple mods - Thanks!

Nomads now claim to have 70W spindles. Maybe somebody like @Julien or @WillAdams can verify that and provide histories for all Carbide 3D updates/upgrades to both Nomads and Shapeokos?

Great tips and insights, thanks!

https://web.archive.org/web/20181113230546/https://carbide3d.com/nomad/

From November 2018, 70w motor is still there…

Going back to early 2018, it looks like it was listed as a 50w motor.

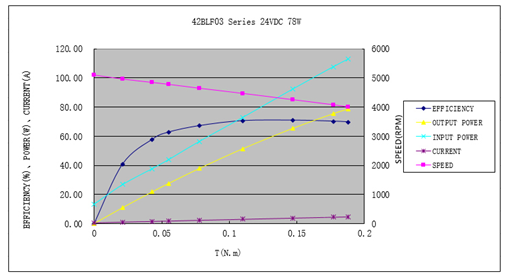

I have no insider info but this recent thread refers to the 42BLF03 model (spec’ed at 78W), YMMV.

Thank you sir! ![]() IMO it would be a real service to folks if Carbide 3D would provide product upgrade info when hardware and software changes are made and upgrade paths/products for them if feasible. (Tracking via hardware and software versions?) Are steel belts now standard on Shapeokos?

IMO it would be a real service to folks if Carbide 3D would provide product upgrade info when hardware and software changes are made and upgrade paths/products for them if feasible. (Tracking via hardware and software versions?) Are steel belts now standard on Shapeokos?

The definitve motor upgrade thread thx to @mikep.

Nomad spindle motor....upgrade?

I suspect the easy way to tell would be to measure the body length - ~63mm = 42BLF02 ~79mm = 42BLF03.

My 883 Pro is 2017 vintage

Where possible we provide upgrades such as our Maintenance Kit and Z-Plus.

Other differences are too minor to really track. It’s not like there have been that many changes/versions:

None of these are Nomad upgrades…

Good point — but none of the Nomad upgrades have been really differentiable. There’s just:

None of them share enough parts for a commercially viable upgrade from one to the other.

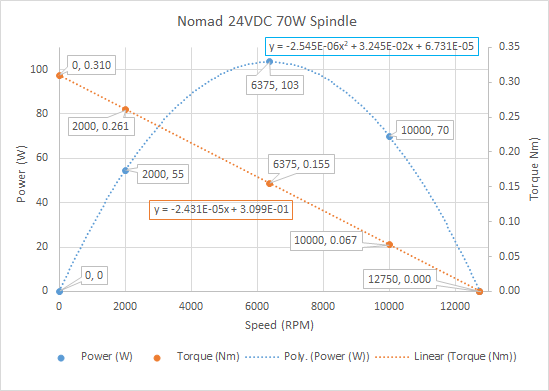

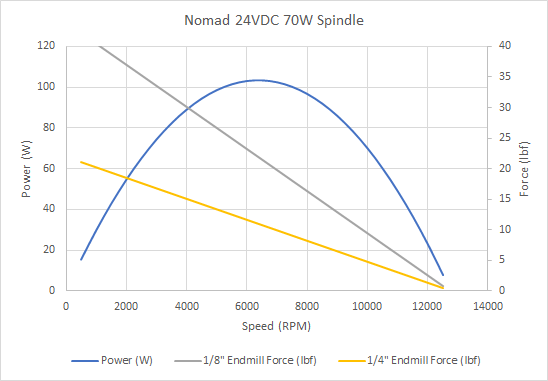

Assuming their chart is correct (which differs from their table), I extrapolated its data to provide power, torque, and force data over a broader speed range after compensating for the 2.5:1 spindle drive pully ratio and a presumed 70/79 = 88.6% spindle/drive inefficiency. IMO, the force chart pretty clearly shows the benefit of increasing speeds (rather than torque).

I’m an idiot who doesn’t know what I’m looking at, could you elaborate? ![]()

Do these charts relate to MRR somehow or something like that?

My stock 2019 machine would appear to already be running a 42BLF03 … or something similar around 70mm or so.

Material removal rate (MMR) = Power (HP) X K-factor (cubic inches / HP). 1 horsepower (HP) = 745.7 Watts (W). (Unlike the US, most of the world uses Watts for mechanical power as well as electrical power.) There’s K-factors for a variety of materials on worksheets in the SFPF Calculator Excel workbook.

Both GWizard and HSMAdvisor speeds and feeds calculators can use torque/speed curves to keep cutting recommendations within spindle power/torque limitations. HSMAdvisor now can also use machine force limits, which generally is at lot more useful for CNC routers. GWizard doesn’t even display cutting force.

If MRR is a multiple of power, don’t the graphs indicate that rather than increase speed, it’s better to keep it around the middle, at 6375 RPM?

That would be the case if the machine could provide the necessary cutting force. If I remember correctly @Vince.Fab keeps his force around 3 lbf on his Nomad.

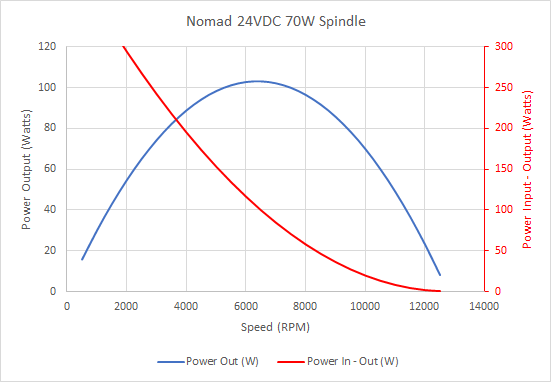

Motor heating, which is proportional to the difference in input and output power, also increases as speed decreases as shown below.

Ah - that is interesting - looks like there was a bit of a motor swap at some point - question is - to what?

That doesn’t sound right. The manufacturer’s chart you showed earlier shows that the efficiency is highest around max torque, which is lowest speed. The higher the speed, the less efficient, the hotter.

Or am I misreading that chart somehow?

Ahhh wait, I see. Your efficiency chart is absolute, theirs is relative. 80% efficient at 100W = 20W of heat, 80% at 50W = 10W of heat.

But if the Nomad could handle the torque, I think what you’d look for is peak efficiency rather than minimal absolute power loss, right? That means optimal power/MRR conversion. You might put put more heat per unit time but you’ll do it for less time so the overall loss will be reduced.