Perr

December 18, 2023, 12:54am

1

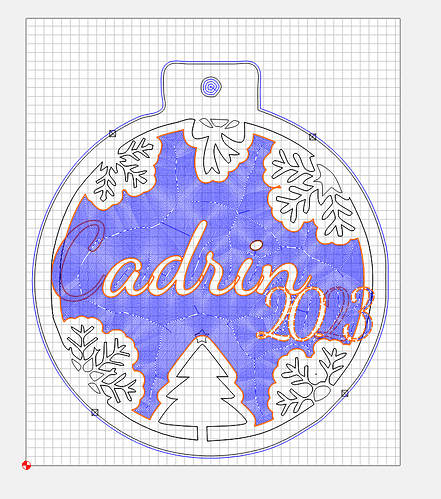

Hi I am new to CNC and been playing with the prgram a couple of days now and was wondering if anyone could help me out?

Im am trying to pocket out a space but it keeps grabbing some of the letters and numbers??? I am partially at were I want to be but cant figure this out. See below image.

Thank you

WillAdams

December 18, 2023, 1:01am

2

You will want things not to overlap.

For the text see:

https://carbide3d.com/blog/merging-script-fonts-in-carbide-create/

and you’ll need to use Trim Vectors for the rest, and it will probably be necessary to have two separate copies of the script text.

If you have difficulties with this, post the file.

Part of this is Figure-Ground reversal — see:

This came in from support difficulty in getting a purchased image:

[image]

to cut as desired.

We will review the specifics here.

1 Like

Perr

December 18, 2023, 10:42am

3

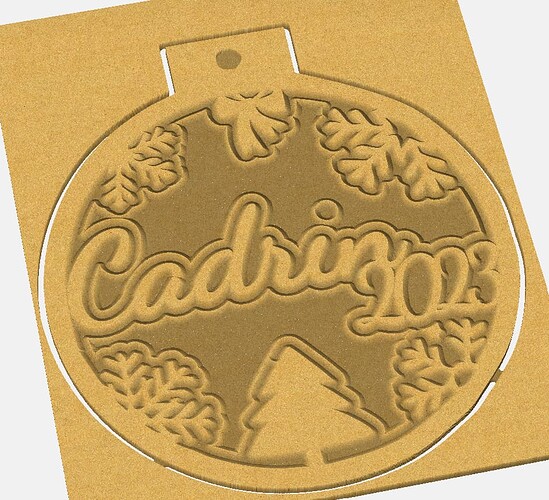

Thank you @willadams , this worked great!!! I was even able to add other detail as well with advance vcarve.

WillAdams

December 18, 2023, 11:56am

4

Glad it was helpful!

Are you cutting a slot just as narrows as the tool around things?

Where possible avoid slotting and add geometry and cut as a pocket

While cutting up vacuum extension wands for this is expedient, it’s a bit problematic given that Shop Vac recently filed for bankruptcy, was bought at the last minute, and production hasn’t caught up.

I need a receptacle for the Sweepy 2.0 dust fitting — one option would be to purchase one from Woodcraft, but Carbide 3D sells blocks of HDPE:

which looks to be just barely big enough for things to fit.

Measuring the hose fitting I get a diameter of ~63.5mm — offsetting that twice we arrive at…

and/or

One technique which is often suggested to avoid slotting is to add geometry around a part which one wishes to cut out and cut as a pocket down to tab depth — here’s one technique for that.

In this case, the project is a bevel gauge which will be cut out of 0.0625" (~1.5mm) thick aluminum:

[bevelgauge]

Due to the narrowness of the angles, an 0.03125" endmill has to be used, so after importing and scaling the file (we will be cutting out one which is 3") we select the perimeter and offset it tw…

and consider leaving a roughing clearance and taking a finishing pass.

One which has a cutting flute length equal to or greater than the thickness of the stock — pretty much any tool should work.

Big thing is the toolpaths — if cutting out, rather than just cutting a slot:

[image]

Offset to the outside by endmill diameter plus 10% or so:

[image]

[image]

[image]

Then cut as a pocket:

[image]

down to tab height or the penultimate pass:

[image]

then move the contour down to below the pocket and start cutting at the bottom of the pocket:

[image]

and…

CullenS

December 18, 2023, 2:32pm

5

@WillAdams have you seen the other threads with pocket issues such as this one:

I’ve got another instance of the pocket operation doing things stupid and slot cutting it’s way down. I was trying to avoid slot cutting, but here we are. I thought this was supposed to be resolved? CCreate v746 MacOS.

Small ButcherBlock.c2d (348 KB)

The toolpath in question is the final perimeter cut.

Any guidance on that? Is 10% over the tool diameter a magic number that if exceeded the behavior is different? Advising a pocket that ends up cutting as a slot anyway is just a time consumer.

To be fair, I am not running the latest build of CC. When I get back from Vacation I intend to upgrade both CC and CM to the latest levels.

1 Like

RichM

December 18, 2023, 5:01pm

6

The star at the top of the tree that appears in your design is missing from the simulation.

You may have planned that, but just pointing it out if it slipped through the cracks.

1 Like

system

January 17, 2024, 12:54am

7

This topic was automatically closed after 30 days. New replies are no longer allowed.