I have been trying really hard to research speeds and feeds but am just getting frustrated at not finding much help. I have already ruined a couple starter projects and broken a 1/8 bit and I am thinking that the auto plunge rate is to much. Where can I find a good list of speed, feed, and plunge rates for multiple bits used on soft and hardwood? I have clicked on endless links and can only find maybe a 102" or 202" list or nothing helpful at all.

What CAM tool are you using?

Current versions of Carbide Create have quite conservative feeds and speeds for many endmills in both hard and soft woods.

See Intro to CNC - Part 5: Feeds & Speeds - YouTube for concepts on this and see the series #MaterialMonday: #MaterialMonday on YouTube for specifics.

You should test feeds and speeds in a piece of scrap using the technique at: https://precisebits.com/tutorials/calibrating_feeds_n_speeds.htm

Another consideration is Climb vs. Conventional Milling and tooling engagement — where possible avoid slotting and add geometry and cut as a pocket (Making vacuum hose adapters and/or Adding geometry to cut as a pocket with a finishing pass ) and consider leaving a roughing clearance and taking a finishing pass.

Extensive discussion at: Origin/consistency of chipload recommendations and Feeds & speeds - Shapeoko CNC A to Z with a spreadsheet for this at: Speeds, Feeds, Power, and Force (SFPF) Calculator - #29 by gmack

Were you using the default feeds and speeds in Carbide Create or your own when you broke the bits?

Julien has an ebook linked on the forum that adresses f&s as well as many other subjects. There are several f&s links as well. Have you searched for any of those on the forum? Unfortunately there is no one answer for any of your questions.

I use the cc defaults and although slow they work for what I have done so far.

Thanks I will check those out. I am just using Carbide Create right now. I haven’t changed anything since I am unsure except for a couple things I have seen some youtubers do, but no changes with my 1/8 settings. Like I said though, it broke very quickly so I think the plunge rate was high maybe. It defaulted at like 18 plunge rate, 60 feed rate, 18000 rpm, .020 depth per pass on common board.

Yes I just used the default. I followed a couple on Julians links, but I could only find 1/4" bit feeds or the link didn’t work.

Any chance your Z-zero was off and you plunged too deep? Those settings are really conservative.

I don’t think so. I mean I zeroed the exact same as every other time. It is only that bit that I have had trouble with.

You said it broke fast. Is the cut deeper than half a millimeter?

What but are you using? Are you using an 1/8" collet or an adapter?

I’m with Neil on this one, those settings should work, assuming the actual depth of cut was indeed 0.5mm / 0.020" ,which is very conservative in wood, so something else is going on and cutting deeper than expected is a likely root cause, that or excessive runout (hence Neil’s question of collets/adapters).

If you would like proven recipes, from my experience the feeds and speeds in CC database are quite trustworthy as a starting point.

If you want a general rule to figure out decent feeds and speeds for any situation, there is none but the closest approximation I could come up with is what’s described in the ebook’s feeds and speeds section:

- look-up a target chipload in the table for the endmill/material combination you want. For a 1/8" in softwood, the table says 0.001" to 0.0025" chipload for example.

- pick a set RPM, higher is better, say you want to stick with 18000RPM

- determine the feedrate that will grant the desired chipload at that RPM value. Ignoring chip thinning effect, and assuming your 1/8" endmill has two flutes, in this example feedrate would need to be between 0.001 x 2 x 18000 and 0.0025 x 2 x 18000, so between 36ipm and 90ipm. Your value of 60ipm is right in there.

- finally, pick a depth per pass using the rule of thumb of 10 to 50% of the endmill diameter in that example, so between 0.025" and 0.125". Your value of 0.020" is even more conservative, so quite safe and nowhere near a tool-breaking-value is everything else is ok.

- plunge rate, I like to keep it to 30 to 40% of feedrate in wood. Your 18ipm is quite fine.

I’ve had my share of confusion (about feeds and speeds) and initially breaking tools, but so far those guidelines have worked well for me.

I just broke a 1/8th endmill on some purple heart with the plunge rate at 25 and feed at 35 going .10 deep. I knew I was pushing the limits but I was in a rush, ended up backfiring on me. Hope this helps with rates to we wary of. 35 is a decent feed rate in my opinion, but not going into a hard of wood as purple heart

I would be interested to know if it broke during a plunge or lateral move, and what was the RPM, and how fresh/sharp the cutter was?

That does actually help a lot thanks.

Yes I am using a 1/2 collet.

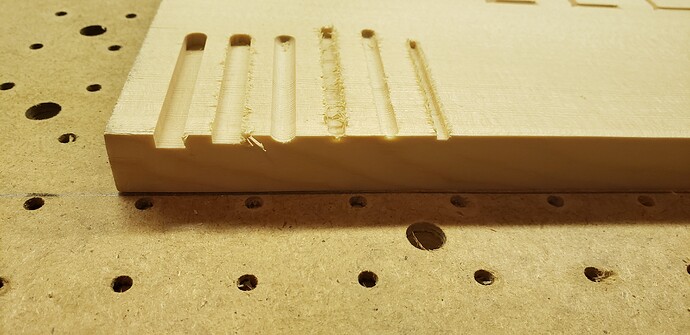

I just got the cutter last week. It’s brand new. Looking close it broke during a plunge that I don’t think it should have done. On two separate cuts, of the same thing, it decided to plunge about the time it should have been done with the project. I will attach pictures. The bit still seemed pretty tight in the router so I don’t think it was sliding deeper, but idk. The stained image is where the bit actually broke. The first one I was able to stop it, but it went far deeper than when it broke. Neither one should have gone down though…

Looks like you’re trying to cut too wide an area w/ too narrow an endmill — try advanced V carving?

It does look like a slipping endmill though. In your upcoming tests, you may want to put a black or white mark on the endmill shaft where it exists the collet, that way after a cut you will at least be able to tell visually if it did slip. We have had a few cases where people where tightening super hard and still had slippage for a variety of reasons (dirty collets, faulty collets, dirty taper where the collet sits, …)

Which Z axis do you have?

Right that is still a big possibility. I will mark it and see if it slides.

I think that it is the z plus with the shapeoko 3 xxl.