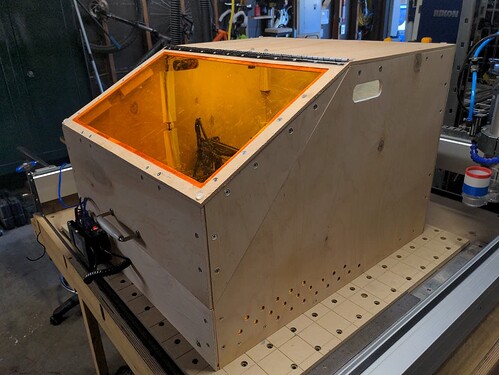

I made an enclosure for my new Atomstack X7 laser.

The wood is a really cheap grade 6mm baltic birch I salvaged from machine packing crates years ago. This was my last full sheet, I had about 50 or more originally that were 4’ x 4’ or larger. All the screws are mismatched because I went through and found whatever I could in the thousands of screws I’ve saved to put it together. For the box itself, my only costs were the piano hinge (which I know I have a two foot section from another project somewhere…) and the laser safe plastic from Jtech.

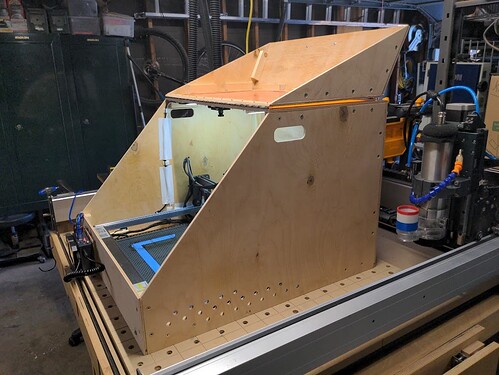

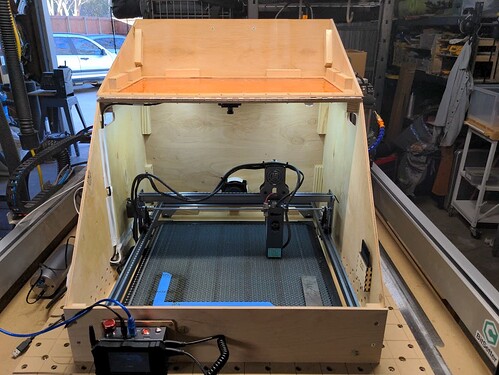

The laser is bolted to the front so it is secure in there. This will help for transportation and with camera positioning for Lightburn (if I can ever get the camera to be recognized by Lightburn in Linux, but that’s for a different forum…). Built in cabinet fan with a quick detach 20’ vent hose. LED lights bars on on the top.

For anyone interested, here is the svg file. It should work for other similar sized lasers. Dimensions were based on allowing full movement of the carriage and getting enough height for the camera to view the bed. The base panel is in a slot in the side/front/rear panels for strength. Everything else I went simple with 1"x1"x4" blocks and screws, you can see in the photos.

12x24 Laser safety panel

Quick disconnect vent

25’ plastic covered dryer vent

Quiet vent fan

LED bar lights

Wide angle camera

3d print file for Cam Case.stl (161.8 KB)

If you decide to use these plans, you should reposition the drill holes on the side panels. Because I had them lined up, when you try to put a screw in from the top and then the side, well… they hit each other ![]() I had to run some in at angle. Also, I chamfered the lid panels on my table saw, set the angle using the lid side piece.

I had to run some in at angle. Also, I chamfered the lid panels on my table saw, set the angle using the lid side piece.

Anyway, this was a quick-and-dirty Shapeoko project, functionality (mostly) over form. It does what I wanted which is contain the smoke and the vent fan pulls it out quite well even though it is a smaller fan.