Here is the completed project.

That looks awesome!

Thank you. It’s posted on CutRocket.com. Not sure if they have it available or not. Haven’t been there in a minute.

Went and looked and it is posted under “Household”.

Got my feet wet with my new Pro XXL today. Found the “Friends Frame” on CutRocket and decided it would be a good practice run since there was a bit change involved.

Itty bitty snail, testing out a ball socket for joining jewelry pieces to create movement. Think the antenna is pushing the wood a little too far at this size though

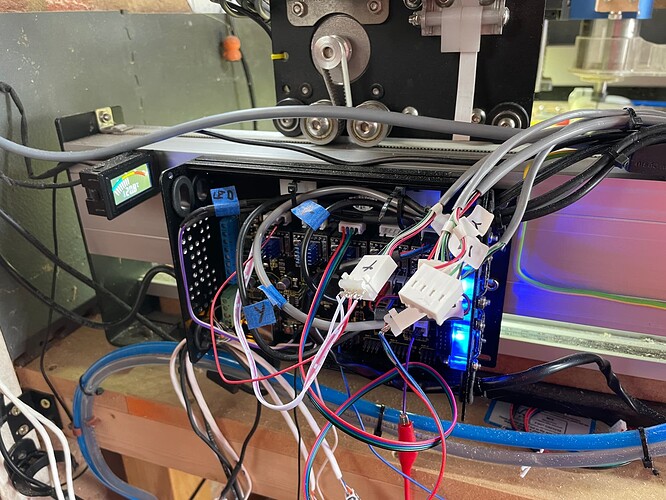

Closing the gap between my 3XL and the newly announced HDM… 4th Axis on my 3XL HDZ

It’s a very deep rabbit hole, but I’ve got it fully up and working. The first hurdle being that the standard electronics only supports XYYZ axes, with no spare capacity or IO pins on the controller. I researched various alternative controllers, but settled on the KeyeStudio MKS 1.2 combined Arduino 2560 and RAMPS 1.6 on a single board, hosting the Grbl Mega 5X branch of code.

Specs:

- KeyeStudio MKS 1.2 Arduino/RAMPS Controller board, 6 channels plus the usual limit sensors, PWM, probe IO etc

- Step-Stick 2209 drivers x 5

- Power supply 24V 15A with fan cooling

- Grbl Mega 5X branch of Grbl uploaded using Arduino IDE

- “from Amazon” 4-jaw spindle with Nema 17 driver and 4:1 belt drive gearing

- Aluminium case for the electronics with miniature cooling fans

- Universal G-Code Sender (UGS) with ABC axis enhancements (hopefully due to make 2.09 release)

- Existing Huanyang VFD with 800W water-cooled spindle

- Fan water reservoir/cooler with modification to engage the fans only at 28c

- Laser cross-hair XY zero ‘pen’ “from Amazon” enabled from a spare IO on the controller

Video of the axis running, making a test piece:

The electronics need to be tidied up… but hey, it’s all working

So worthy of it’s own thread.

Lead us [the blind]!

I was dipping my toes a little into 4th axis territory, but put it off for a little bit. My interest has been piqued once again.

Wow, very small! Nice!

Wow very nice. I can’t help but wonder if there is interest in a custom controller board that fits in the existing enclosure but adds an extra stepper as well as a separate PWM output for laser, and anything else that can fit.

That’s awesome! How much does a setup like that cost?

@ctdodge About $250 all in, plus self-time putting it together and configuring Mega 5X, and contributing to the UGS code development. Will itemise the costs when I get a moment

I really like this idea. Did you do the grid on the whole surface or just cutting area? What was your process?

Are you willing to share the .SVG of the castle?

Of course. Here is the SVG file. I used the Waltograph font which you should be able to find online.

Castle Sign.zip (73.4 KB)

I soooo, want to get to that point. “Baby steps” I have to keep telling myself!

Just the cutting area was the space used for the grid. Didn’t see any use to do the rest.

So agree with that… We NEED to know more ![]()

Approximately 15 years ago I cut down a large (15" diameter trunk) Bramley apple tree that was growing in my garden. It was full of mistletoe that I was fed up with removing, (luckily I still had two other, equally large Bramleys). I had it planked into 2" boards and it has been sat waiting for me to think of a use for it ever since. Then along came the Shapeoko and my newfound hobby.

The moral of my story is that you can spend as long as you like watching you tube videos etc., but it’s not until you actually start cutting that you learn and I learnt lots making this board.

Quite a few new cuts for me: the finger grips, the chamfer for the engraving and the very small, close together leaves and apples. I am still amazed at how accurate and capable the Shapeoko & Vectric are, the stalks on the apples are a maximum of 1/16" wide, they all cut perfectly.

The only thing that I would change is that instead of using Osage for the apples I would have liked a green wood, similar to the the colour of a bramley. I have some greenheart but mine does not live up to its name!

As the experts on the forum will already know, the stress levels build with each additional cut, I was sure that a cut was going to go wrong and I was going to ruin it. I guess the apple gods were watching over me!

**

Somewhere within, I can’t fathom putting a knife to that surface. I understand that feeling of relief when its done, handing it over to be purposed and placed in someone else’s control that didn’t stress over every cut.

It would take a while for me to look at it again. Perhaps that’s just me.

Wonderful! +1