Drop a few hints from time to time, especially around other family members. I think I’m on course for that new tackle box I’ve been wanting…

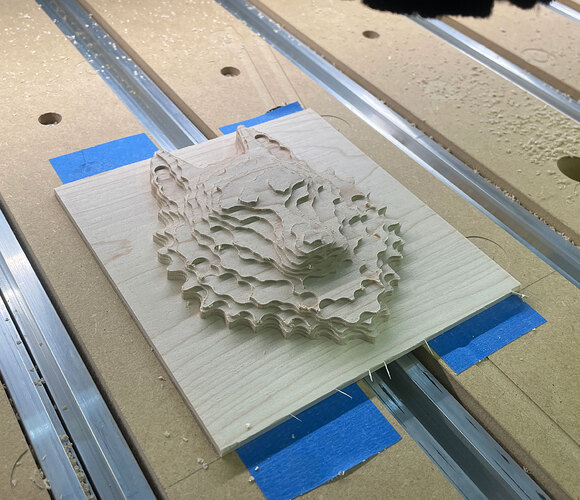

Just playing around and getting familiar with 3D carving.

5" x 5" x 3/4" hard maple.

1/4" bit for roughing

1/16" ball nose for detail

about 2 hours to carve.

That is superb,detail is outstanding and I think the oil/varnish is great.Well done

The image is created using https://spiralbetty.com which allows you to create this and export as svg.

Using an advance VCarve in carbide and a 45° bit it kinda just auto does it. You do have to play around with the depth to get it right. I think this one was a v carve with a max depth of 1.25mm

You all have me home sick. I am out of town doing work and now missing my shop and my machine. I have been working on my computer to design a few things here and there while I’m away, but nothing compares to being there with the machine and running parts off of it. I go back home in about 2 to 3 weeks.

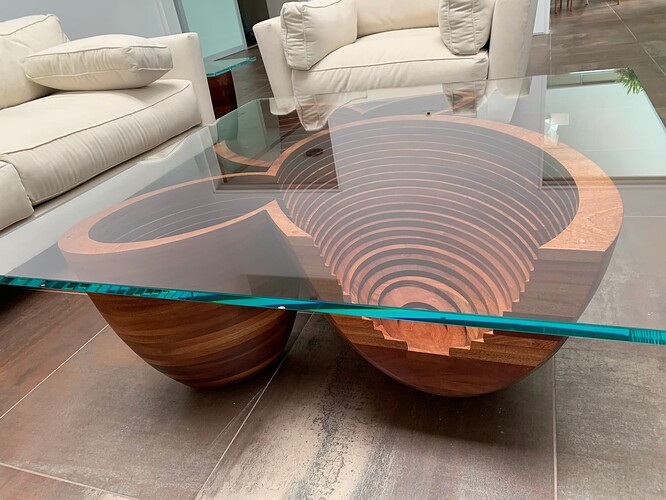

OK…This isn’t what I made today - but it’s what I’ve been making over the past 3 months. Delivered them to the client today.

3 Pedestal tables - 1 Coffee Table and 2 Side Tables.

EDIT: Thank you to those in the forum who helped me with all the techniques to make this work. It used STL Imports and Tiling from the Pro Release.

Gary

Wow. I can see why that took 3 months. A lot of moving parts to put together. Looks great. I bet that glass was quite expensive to get made. Very nice form and function.

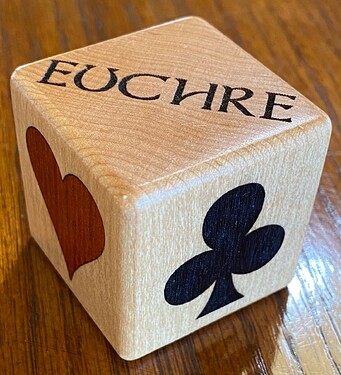

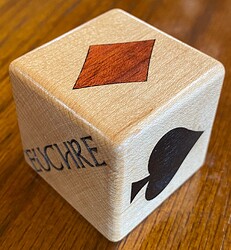

Euchre Trump Suit Cube

Euchre is a fast-paced 4-person card game where the trump suit varies with each hand, so it’s sometimes hard to keep track. During a hand, somebody ( my wife ![]() ) will always ask, “Wait…what’s trump”? This cube lets you mark the current trump suit by putting the trump suit on top.

) will always ask, “Wait…what’s trump”? This cube lets you mark the current trump suit by putting the trump suit on top.

The cube is hard maple and measures 1.5". The pockets and inlays were cut with a JTech laser on my SO3. The Club and Spade are black-dyed veneer. The Heart and Diamond are Bloodwood veneer. Finished with a few coats of wipe-on Poly.

That looks great. How big is the cube?

He said it was 1.5" hard maple.

I have some maple legs from an old router table I inherited from my dad. The table was sagging so I tossed it, but I’ve been using the legs for various projects. They are some kind of rock hard maple with small growth rings, as you can see in the first picture. 41 growth rings across the 1.75 inch diagonal!!

Tough as nails. Really great for custom lathe tool handles, and now the euchre cubes. Now that the family has seen them, I need to make about six more ![]() . The legs are 1.5"x1.5", so that’s what the cubes are.

. The legs are 1.5"x1.5", so that’s what the cubes are.

That old wood is the real deal wood. Nowadays the wood is grown so fast to hurry and get it out the door for product that it doesnt have the hardship growth that that old wood had. I have seen a person get some 100 old pine beams that came out of a building in an old building from a business that caught fire. He worked the wood and said it was the hardest pine he has ever worked with. When he dated the wood from the growth rings that were there on the beams, the tree started growing in the late 1700s. He said the timbers were taken for the beams around 1900. Then they stayed in the business for almost 100 years before he got them.

This is why I like finding true old land timber barns that are falling apart and cost me nothing to salvage but my time and effort. Then I take that timber back to my shop and use it for various projects.

You almost made the hand hold that Steve Vai has on his guitars.

On May 5th went to see Joe Satriani and Steve Vai play in Houston. Great show. Here is pic of Steve Vai playing his Hydra Guitar.

My grandson wants me to make a guitar on my Shapeoko. He is working on the design and the parts. I have made a few guitars in the past.

Nice looking maple body.

It’s actually a copy of a Kiesel Tim Miller. Here are some of my SO3 creations.

That’s beautiful. Tell me it’s not gonna be a busy finish. Let that wood do the bragging.

If it was for me, then it would be natural, but the customer asked for blue. However, I’m going to push it with a PRS Northern Lights finish, so it will be some blue, purple and reds that hopefully change as the light hits.

That looks fantastic, great job. What bit did you use to get those clean edges?

I only used the CNC to do the inlays. Sometimes conventional tools are best (and quickest) for certain operations. The cube was cut on the table saw and the edges were done with a 1/8" roundover bit in a handheld palm router (followed by some touch-up with 220 grit sandpaper)

Id like to see how this works!