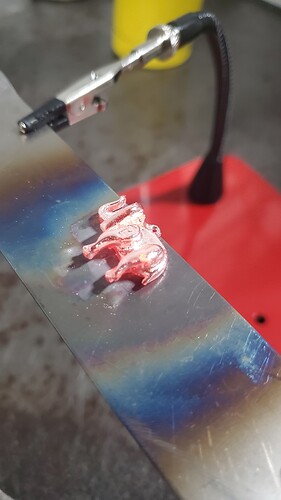

No chips today but did get one step closer to finishing the pure silver Elephant that was machined on the Nomad 3. Didn’t have the right soldering tools but proved the concept and might see where to can lead.

yes please that would be awesome thank you!

This was posted under the graphic posts. Is this what you are asking for?

I really like this. Thank you! This gives me something new to learn, too. Framing isn’t something I’ve worked on, yet.

Thanks again!

You may note, I reduced the cut to 0.125 from the 0.25 you had. I think it adds more detail as well as reducing run time.

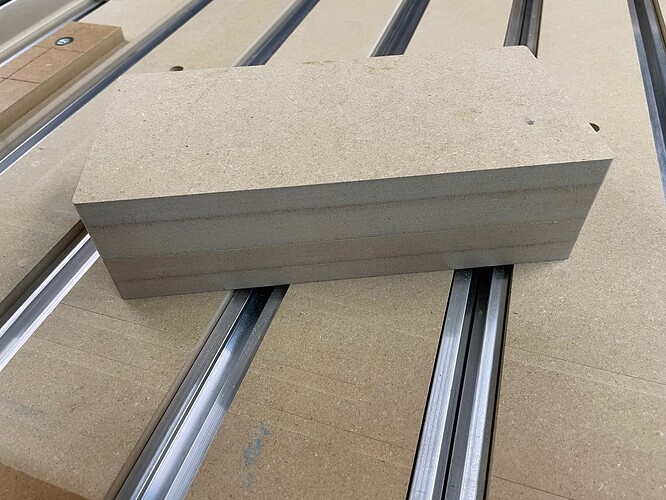

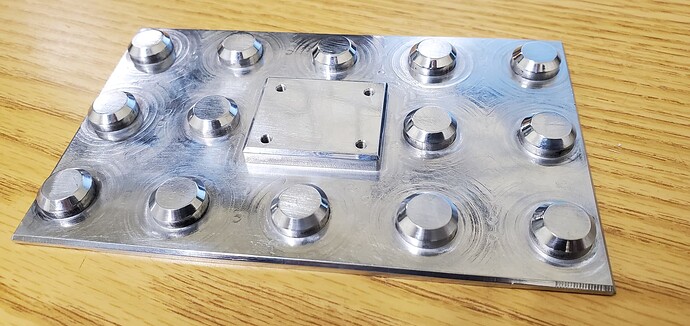

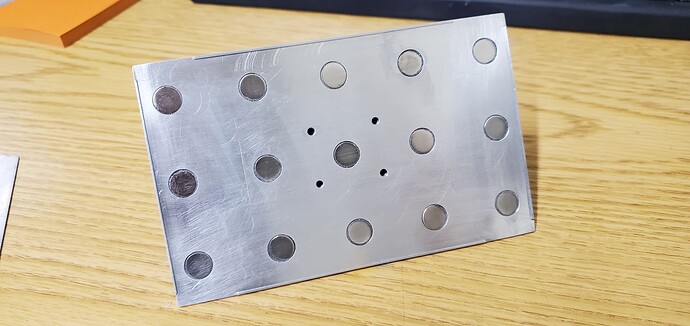

Disc Jig with Cam Locks works!

I had to sand the Cams a bit to get them to lock better but the concept works.

Next I will make a larger one for Coasters.

The jig is nice so I may cut a bunch of blanks for future use.

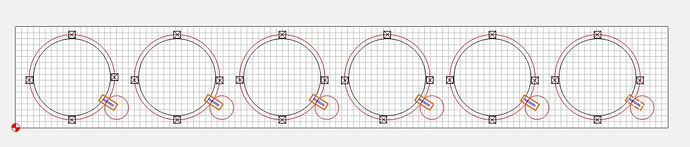

How about a Double Duty Disc Jig with Cam Locks?

Two different size Disc pockets, one inside the other. Say for Small Trivets and the other for Coasters.

Actually I made the first one too big but was able to save the material thinking outside the box.

In this case thinking inside the pocket. ![]()

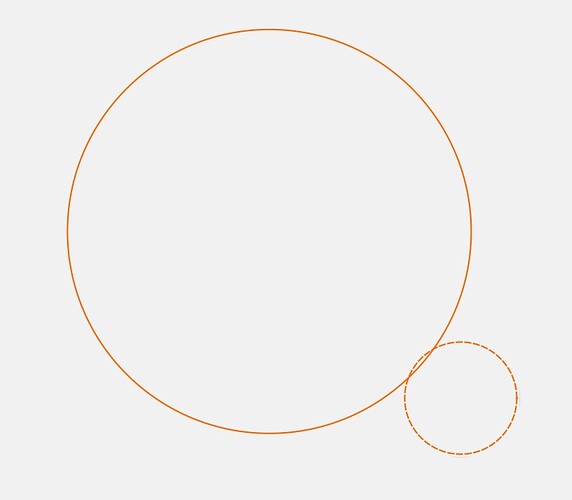

Who needs Boolean?

Apparently, in some cases the need for Boolean is irrelevant.

I created the following in CC.

Selected both circles and created a pocket toolpath and the smaller pocket in the previous picture was done correctly as it would if it were done the other way, as in the larger pocket. Hmm, go figure?

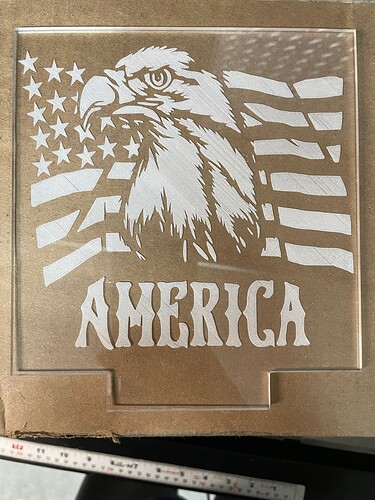

Well finally got my machine two weeks ago and all set and up and running. Very intimidating I will say. Not new to CNC but this beast is intimidating and very hesitant at first as just don’t want crash or screw things up. But good learning curve. Few simple projects to start. Pretty excited and happy

Great patratioc themes. Just go for it. The machine wont bite, well not much.

After I got yelled at for not using the right soldering materials on the first try. Had to go for number 2.

It has character, maybe a little bit o soul. Fine 999

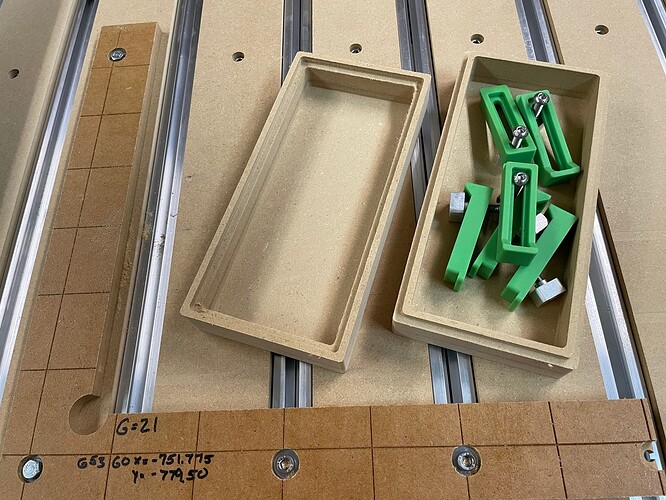

Modification to my 3.6 inch Disc Jig for coasters and what-not.

I added a pop-out slot to aid in disc removal from the Jig.

I also found a pop-out tool laying around the shop.

Multipurpose Disc Jig.pdf (332.7 KB)

This jig works great! Created using groups & layers in CC.

Within this CC file I have the Jig cut, Disc cut, Cam cut and the coaster pocket. Turning on and off makes this kinda fun to use.

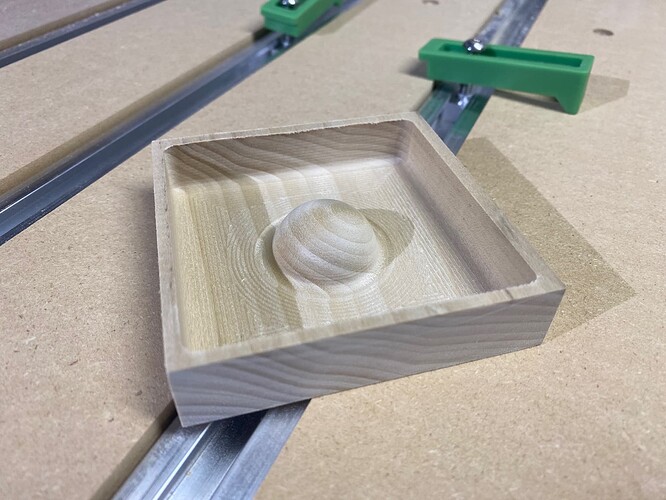

I did a little test on my newly built S4 XXL. These Amana bits are worth the money. Done in Fusion 360.

Also my first post!

Welcome to the Community!

Nice work!

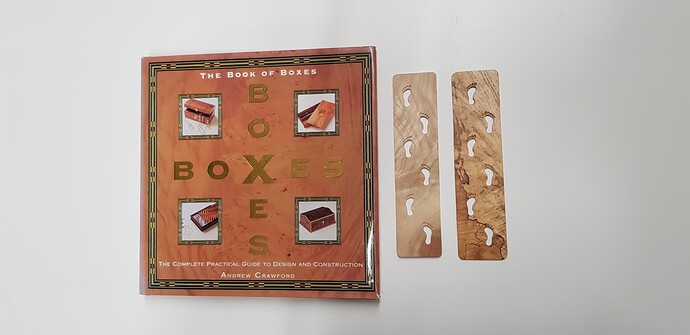

Cut a couple of simple bookmarks out of ash (one spalted) for a pair of globetrotters.

2mm thick, book for scale.

Got lucky as the second one cut was just about to do the profile cut out when the router bushes reached the end of their natural & the router stopped. Poor maintenance on my part, new ones on the way.

My second test cut on this machine. 6061 with the #201 that came with my S4. Started at CC’s recommended feed rate but it was too slow. My calculator said 72ish so I went to 70 and it worked great. I am so damn impressed with this machine. This is only the second week I’ve been doing CNC, fortunately I have been working in Inventor and Fusion for 12 years!

This is gorgeous. I honestly have stopped using almost anything other than Rubios Monocoat. It is just to easy. Although I can see how the tight spaces might make that challenging on this project. Well done

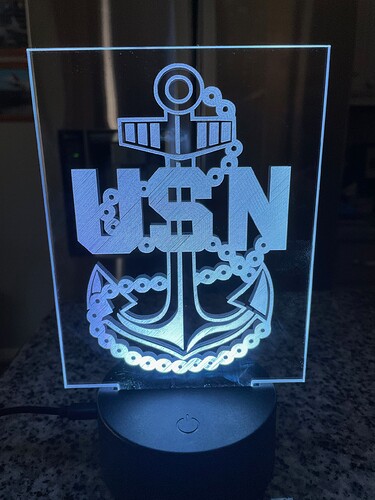

@Goshawk29 Love the Anchor but I might be bias (Current Navy Chief). You projects look great. This is largely the type of stuff I do too. Retirements and going away gifts. Keep it up

test run on a cribbage board. a nice piece of Jatoba

working up to using the desired piece now, a figured piece of torrified (roasted) maple.

The etchings look great! Go Bills!