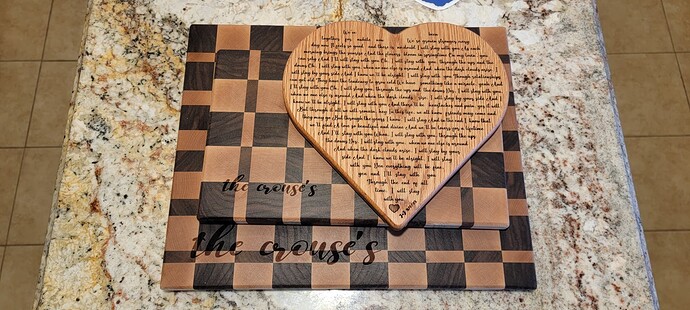

Salvaged / repurposed a couple orders that were cancelled by customers .

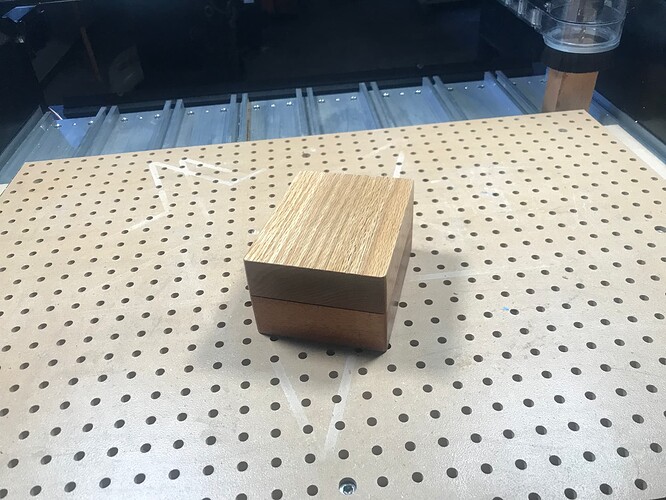

A home for my Stingray out of oak and Sapele scrap using a parametric box Fusion360 file derived from this guy a few years ago. Learn Fusion 360 or Die Trying LESSON 5: Understanding Parametric Design and Modeling - YouTube

I looked up the Rubio Monocoat- it seems this is for flooring primarily. WHat is so special about this finish? I see it is linseed oil based but the drying time is excessive. " The dry time of 2C Oil is 36 hours. It will be water resistant in 7 days." Maybe you can tell me more about which one & how you use it?

Thx

AZ

There are a few had wax oils that came from flooring and have been used in woodworking. Monocoat is a durable and “clear” finish that doesn’t yellow a lot of wood species. It’s very easy to use and a little goes a long way. Also Rubio sells an accelerant that reduces that dry time significantly.

I tend to use Odie’s Oil as it is super easy, totally safe, smells great and produces a fantastic finish.

The coatrack above is finished in Odies.

@mattbenimble hit the nail on the head. Although the Monocoat does come in some tints. I mainly use the Pure. 3 parts pure with one part accelerator.

There are some great you tube videos, but it is super simple. A little goes a long way. I pour mine on and spread with a silicone spreader, let it sit for just a few minutes then hand wipe it with a microfiber. I like doing two coats with maybe half a day dry time in between each one. The second coat I let dry for another half then I take the buffer to it with just another microfiber. Makes is shiney but not to much and gives it a nice durable coat. This is a super simple hat box I made with some highly figured white oak with two coats of Pure monocoat. dry to the touch immediately after buffing and the wonderful smell goes away after 24ish hours. And I’m not lying the stuff smells great. downfall is it is not cheap. Let me know if this helps or if you need anything else.

I like the sound of this Odie’s finish. I’ve used the Good Stuff ( Emmet’s “Good Stuff” Wood Finish | Michigan Maple Block) which works really well for food contact items like cutting boards.

Good materials and finishes are not cheap. For my projects, many of which have tight crevases, oils tend to be a better choice than a spray. Thanks for the recommendation.

Odies Oil has been around for a long time. Many turners use it for turning projects.

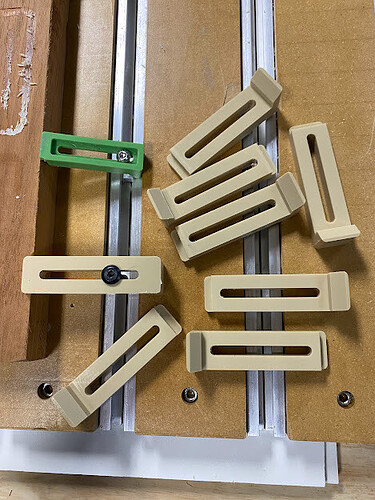

I made some hold down brackets for thicker wood out of some recycled bathroom partition plastic panels.

The material is really easy to cut. The green brackets that came with my Shapeoko Pro XXL are not long enough for thicker wood.

Nuka Cola coasters for when you have had a hard day in the wasteland and need a refreshing drink. Made out of multi colored HDPE. I had to get a 1.2mm end mill to get the script scaled right on these!

That looks like my setup haha https://scontent-atl3-2.xx.fbcdn.net/v/t39.30808-6/277746545_1383369602110659_2310756067809313978_n.jpg?_nc_cat=109&ccb=1-5&_nc_sid=5cd70e&_nc_ohc=_7CDJfdobmUAX9OIfSm&_nc_ht=scontent-atl3-2.xx&oh=00_AT_29KHo_1hnFSs4i_hzX0S8PNfAYhUciQ7HN2CDnCbB7Q&oe=6249F6F5

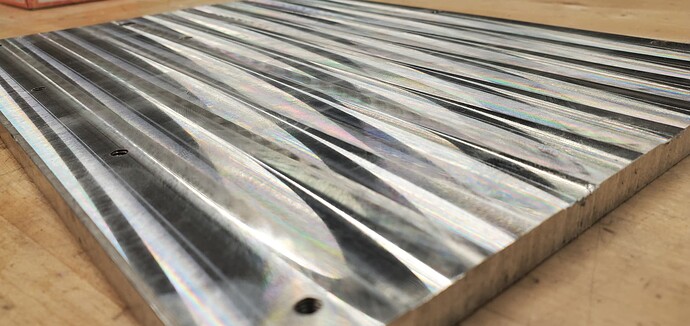

On my HDM I tried the Bush Machine Tools 1", facemill with a 1/2" shank. 0.010" DOC (0.002" of that being a finishing pass), 50 IPM, 0.875" stepover. Came out pretty.

V carved pink flamingos in cedar with cork bottoms. I tried using the stingray on the cork, but in the end a down cut 1/8" bit was what it took. I used stencil material on the top so I could spray the pink and then peel the plastic to leave only the flamingo in pink.

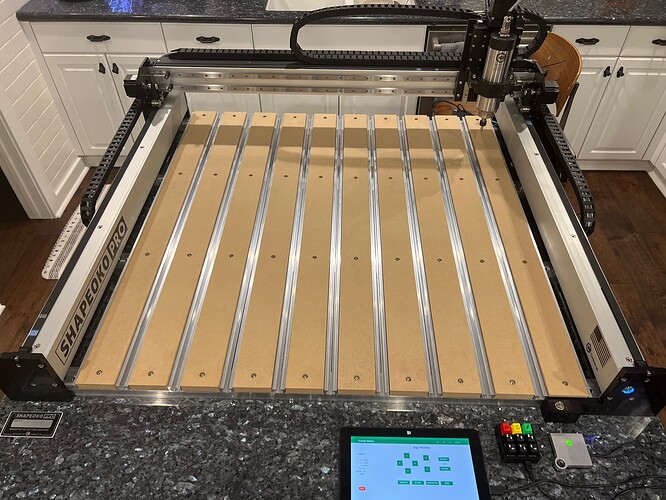

I haven’t been able to cut anything on my Shapeoko today… because I just got it assembled!

Pretty excited to get started!

It’s not assembled until you affix the nameplate.

![]()

Looks like you’re in your kitchen. Will it cut sandwiches? Anyone tried that?

Potato Chips?

All 3 inserts installed? Or just one?

All 3. It seemed to like it better as I went faster.

Just brilliant.

But what next?

What are you using to make your casting molds?