I am at the end of the rope. I can cut things fine in 2D using carbide create. I needed to do 3D so I am using Fusion360. I have worked with Carbide support and have yet to resolve this problem I select a 2D pocket in fusion select bottom height as stock top tell -1in deep. and run it and my pocket ends up at minimum 1.75 inches deep. Check the G code last z registration is .998in So g Code is correct. I watch carbide motion as it cuts and it loses track after the first pass. first pass is .08 deep and CM matches next pass CM says its at .116 but it is not its cutting deeper. ITs not mechanical I have an XXL latest controller and firmware. Machine is not a month old. If I do the same 2D pockets on Carbide create its fine. at least 30 emails back and forth and at least 10 phone calls with carbide support. I have had my files checked by Autodesk and they say they are setup correctly and it should only be going down 1 inch. The answer of well use Carbide create is not the right answer. I am seriously thinking I chose the wrong machine. IF I cant do 3D this machine is useless. Anyone got any ideas I will provide the files if you want them

I’m running an XXL and Fusion 360, been using that pair since I got it, on both original belt Z and HDZ. I can confirm that the combo works so it should be possible to get to the bottom of it.

I’ve had this sort of problem when I confused myself over where my Z zero was on the machine and in Fusion 360 more than once.

Zip and attach the fusion file for us to take a look at?

Are you retracting too high and losing steps? Pretty common if you have a G28 in your program.

You can pick up the files here https://1drv.ms/f/s!Aq45vfPzPdC1jTdHYo70sCLD6jTr

its retract height is .2

Do you have G28 set?

That’s most likely the issue.

Edit: Just looked at a file of yours. Remove the line G28 G91 Z0

yes But i have tried it both with and without no difference

FYI, initial thread here

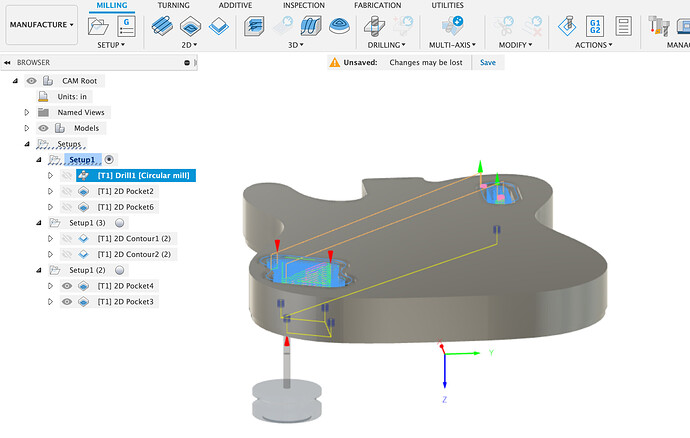

the 2 2D pockets in setup 1

Julien my apologies I have posted on so many boards trying to resolve this. I dont remember. I’ll try and not double post in the future

Doesn’t taking that line out stop it from retracting when it homes?

No, it moves Z to the G28 location you set.

OK,

The pickup pockets on the front of the body and the neck cutout?

(I presume you deliberately set the neck cutout to be deeper than the model when you overrode the depth in 2DPocket6 ?)

Can you describe your series of actions to start the machine up, zero for the workpiece and start the job please?

Also,

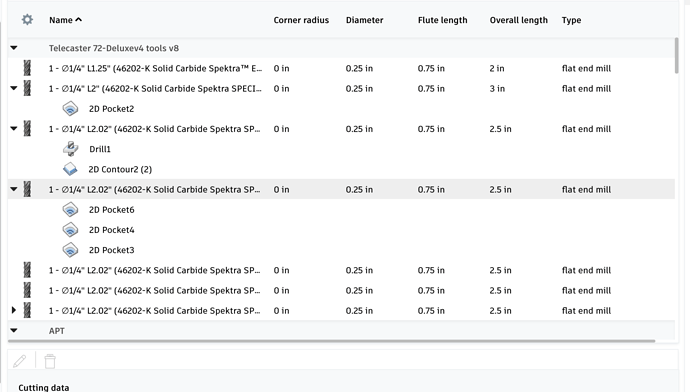

You have two different length tools specified for the operations in Setup 1 but they all have tool number 1 for the post processor so you won’t get any tool change prompt and even if you have the bitsetter it won’t re-zero.

Without looking at the file myself, this looks like the answer. Especially since you are having an unexpected depth difference of .75" which is the difference between the first and second tool “1”

What post processor are you using that inserts TLO commands? Z-zero would remain the same for the job.

That’s true, I don’t do TLO with my Shapeoko. I was in my work mindset. We have a machine with an ATC. TLO does not apply in this situation.

Liam,

I set my zero at the mid point and at the edge. I set the Z height to .01 from the stock. Hit Zero all then run the job. My workflow is the same pretty much for everything. I also tried a test piece Same SVG square inside a square. The inside squares is .125 deep I set Zero ran. The CC version worked fine, didn’t change zero, loaded another stock piece and ran the Fusion 360 version and it went deeper than it should have.SO I am eliminating mechanical issues. It has to be something in the Fusion gCode or offsets in Fusion. So frustrating since this isn’t rocket science. ITs not like I am a novice at graphics software I used to do Graphics for a living and I write and design software as my day job now.

I generate the g code in Fusion and select the Shapeoko post process