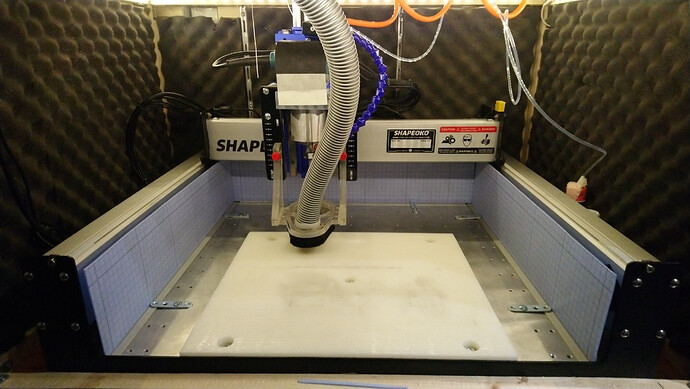

I’m back again with some issues making bowls. It seems I may have jumped the gun. Long story short, I have a woman that would like 100 them, maybe more (Photo 1). So I need to figure out some way to make them somewhat efficiently. Carbide Create allowed me to cut one out in around 30 minutes, no issues. But if I keep going, the chips and saw dust become too overwhelming, the v-wheels “clog up” (Photos 2 and 3) and then the machine starts to lose steps and messes up the part (Photo 4). As you can see in the photos, I don’t exactly have any dust collection (Photo 5). What I’m using is really just the best solution I could come up with on the fly, simply because it “vents” the vast majority of the chips out to the front and keeps them from being thrown upwards and onto the rails. I’ve tried using the Sweepy, but it starts to get really hot on the “inside” - where it’s cutting - and if I’ve learned anything about woodworking or machining, that’s not the best sign, correct? Does anyone have any suggestions? Bellows? Rail Covers?

I’m running a XXL, HDZ with the compact, trim router.

The tooling is:

3/4" Diameter

1/4" Radius

5/8" Height

1/4" Shank.

The material is just regular kiln dried pine, 9" x 5.5" x 1.375".

Depth of Cut: 0.2"

Stepover: 0.375" (sometimes 0.25")

Feed Rate: 60.0"

Spindle Speed: “18000” (6 on the router, if that even is 18000)

Plunge Rate: 15.0"

This is the bowl, right off the machine. Only 99 more.

I was so happy I found a way to keep the chips off the rails I forgot about the v-wheels.

Is there a way to prevent this?

I thought I had it. Haha

As simple as it comes. Worked for a bit. Oh well.