Can the shapokop pro (not the 5 pro) realistically handle aluminium without air assist.

It depends on what you are trying to accomplish. What are your plans?

Yes. (given suitable tooling, feeds and speeds, and toolpaths)

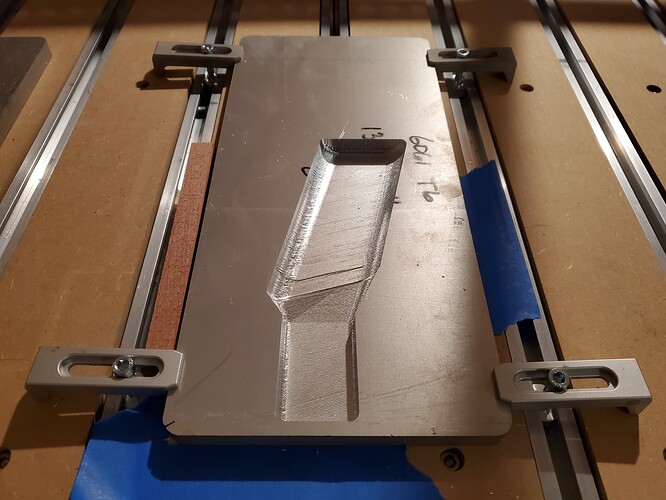

My first project on my SO3 w/ belt-drive Z-axis and 6mm wide belts was in aluminum:

and folks have done quite well w/ that earlier model:

and with default feeds and speeds and tooling my SO Pro had no problems cutting through a 13.5mm alu. plate:

What sort of work do you wish to do? Cutting what alloy? Using what CAD/CAM?

For a bit more on this see:

yes, I have not set up air assist yet and mill aluminum and brass frequently (did some aluminum last night). I use O-flute bits almost exclusively when cutting the metals.

for making small parts like gears and such say max 10mm thick. i don’t have a spindle i’m using a compact router. Do i need a spindle? I see in the comments some others have milled aluminium parts and some look pretty thick so that’s reassuring. I just worry because i had an issue with hard acrylic where the bit got tore out and my colet and bit ruined. Thankfully the machine was ok. I think the issue was the fault of a loose gantry. IDK I’ve been afraid to push my machine after that, I guess.

Nice are you going deep or just engraving. I see allot of people engraving without issue, but i want to cut out parts.

As the bowyers say:

If you ain’t breaking 'em, you ain’t making 'em

Except for a couple of folks who are very experienced machinists and have a natural head for the forces and numbers involved, users who are using their machines break tools:

The worst crashes I’ve had have broken tools, a collet, chewed up dust shoes, and (once) knocked my machine out of square (and we won’t even try to count how many clamps or how much hardware has been sacrificed because of a misjudgement of clearance) — whatever happens, so long as you aren’t hurt (and you shouldn’t be if wearing proper PPE), it’s just a small bump on the road to CNC success.

This is the entire point behind our “Mistakes are on Us” Warranty:

And what is the cutting diameter of your O-flute bits?

I use 1/4" Carbide Spiral Upcut, (Spetools, cheap in a 5 pack but they work well for me)

and these 1/8" on a 1/4" shank. (also spetools)

I’ve broken a couple but every time its been my fault.

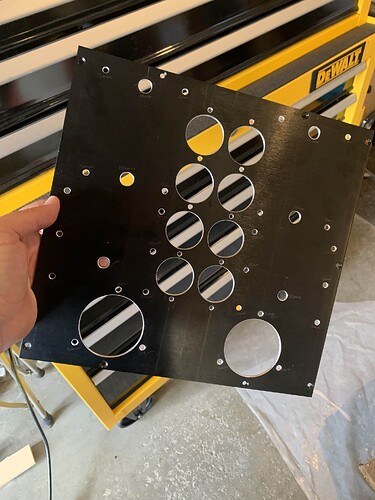

This pic is on the laser, but I cut this last night out of 3mm aluminum sheet.

Otherwise I cut plates and extrusions for people fairly often.

and then brass for leather stamps. which also gets a v bit added into the mix.

I do use a spindle, the noise of the router got to me for long cuts. and the whole workflow and letting gcode set the rpm for me is just much nicer.

That’s so beautiful. Thanks for sharing. This gives me much confidence.

What is it that your cutting @WillAdams ?

A machine upgrade which I want to have compleat before showing off in its entirety.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.