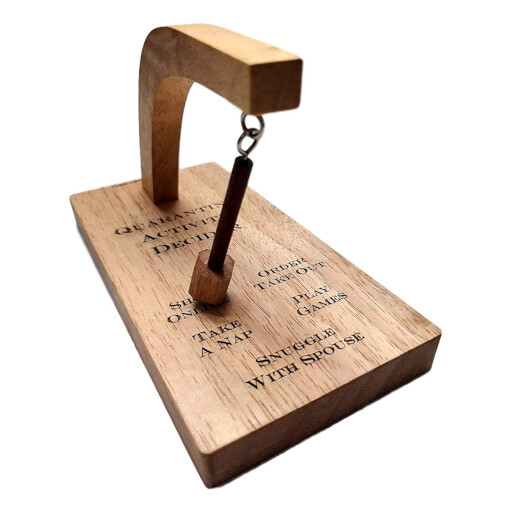

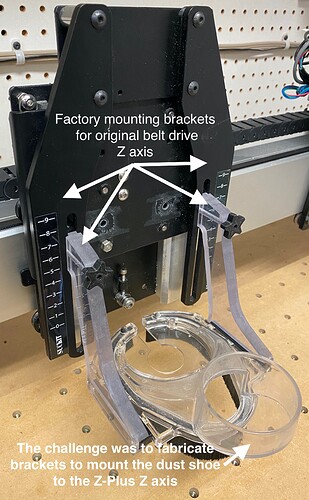

My entry isn’t nearly as glamorous I’m afraid… Here it is:

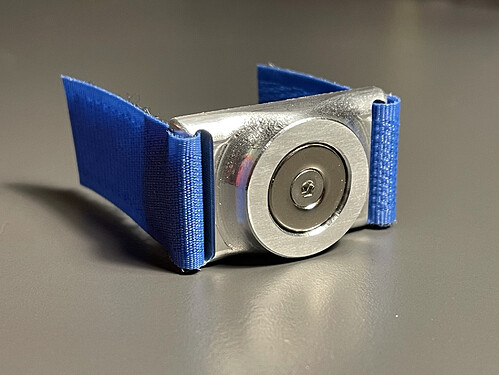

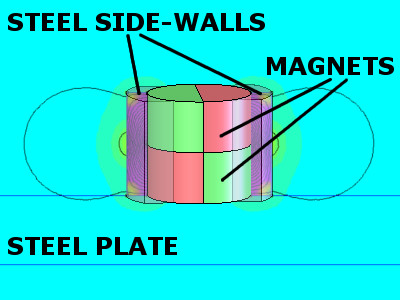

It’s a magnetic hoist:

I got it to hold 8.7kg of water:

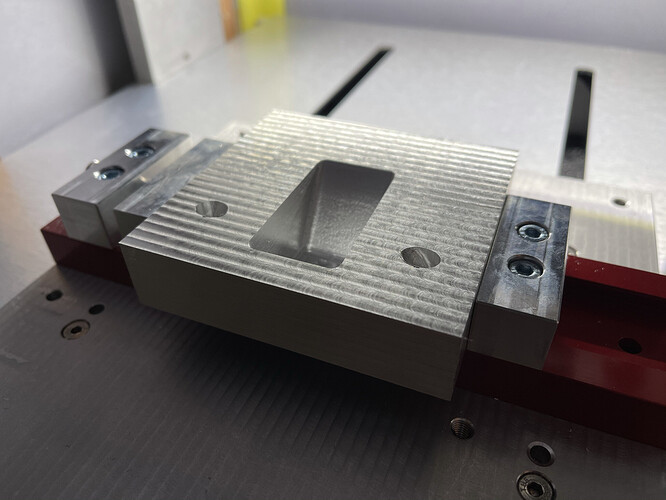

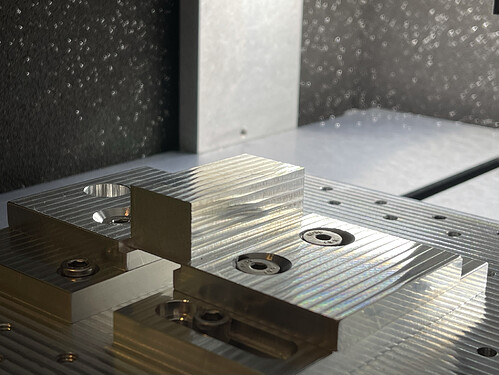

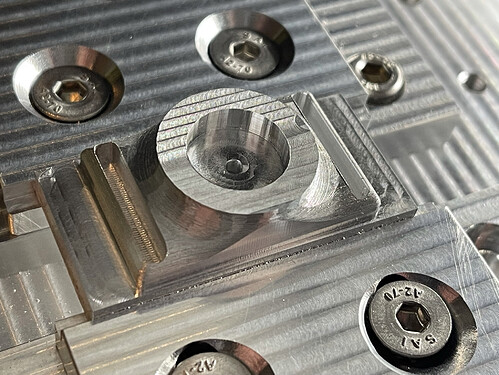

It’s made of two machined parts, one that holds the magnets, and one “cap”:

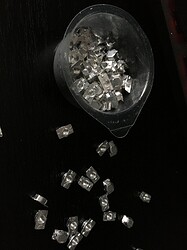

I started this with all kinds of grand ideas. A while ago on YouTube, I saw this video about a 3D-printed magnetic switch and since then had it in the back of my mind to try to mill one. When I saw the contest come up, I thought now was as good as time as any, so I bought a whole pile of magnets:

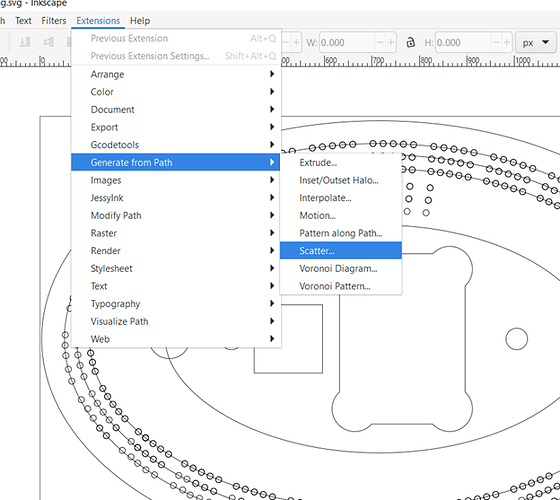

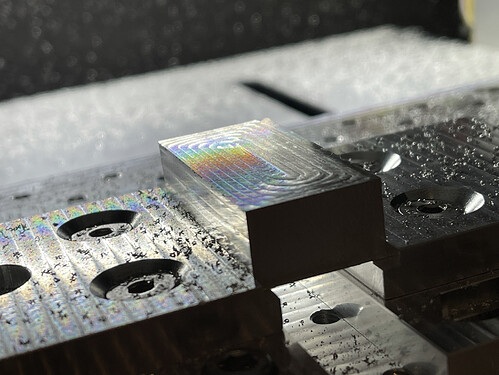

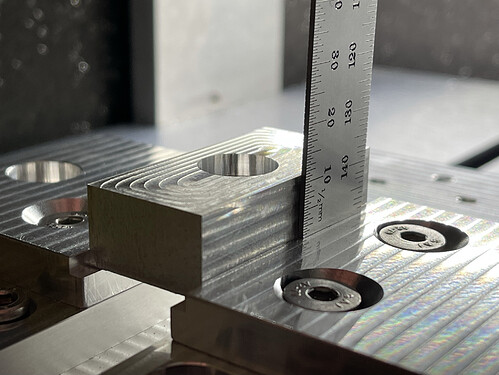

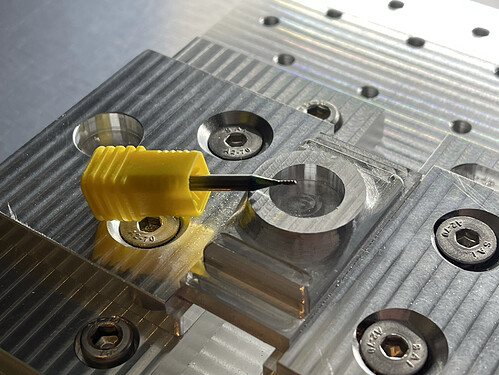

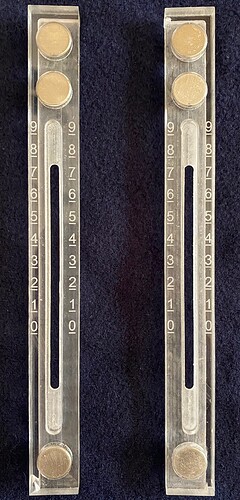

I milled some variable-depth pockets:

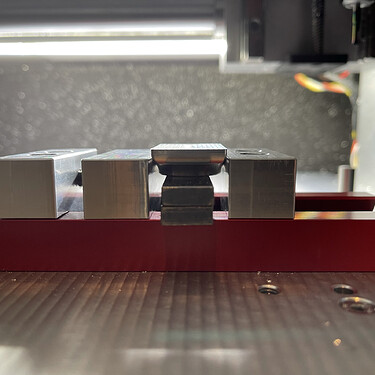

On my shiny new mod-vise

And found that 0.5mm was too shallow (the bottom of the pocket visibly distorted on the bottom) but 1mm was just right.

So I wanted to make a starter project to make sure I could get the magnets to fit, and that the magnetic field was strong enough with the bit of separation induced by the Aluminium. I made the hoist pictured above.

Originally, I planned to have the cap screw on to the magnet holder using threads milled on the inside/outside edges of the cap/holder but when I’d milled the cap, I discovered that it fit quite nicely on the holder… Before the threads were milled… I’d milled out a pocket with the thread outer diameter instead of the thread inner diameter, so there was no material left to mill into threads…

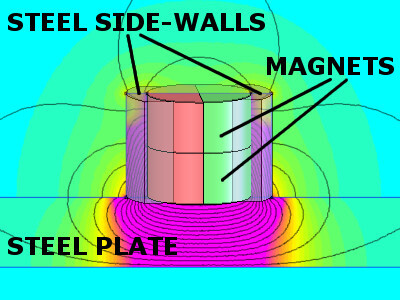

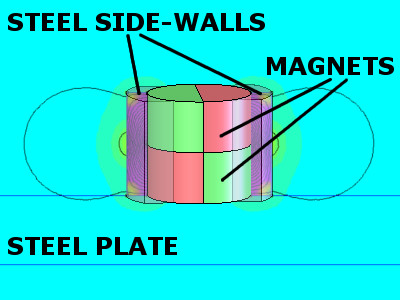

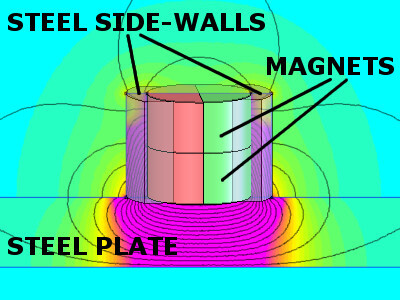

But the rest of the hoist worked, so I started looking into how magnetic switches worked again. Turns out, the fundamental method of operation is turning this:

Into this:

Simple enough, right, just rotate the magnets? I could embed them in a disc like the one I made for the hoist (which was why I made it) and rotate the disks 180 degrees relative to each other.

The problem was that the magnets I bought were all axially aligned, which means the top is north and the bottom is south, rather than being split down the middle top to bottom like in the pictures above.

This meant that I couldn’t just rotate my disc magnets around their axes, I had to flip them like pancakes instead.

Given that I wanted this to be a small disc, that didn’t really work. And given that I couldn’t buy radially-magnetized magnets in time, it wasn’t possible to fix.

I did briefly entertain some ideas of mounting the bar magnets you see in my earlier picture to some little gears that would spin them around their axis but I don’t have the tools to make sufficiently small gears, or the surfaces to run them on.

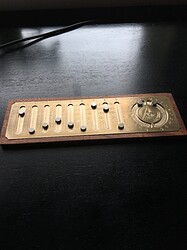

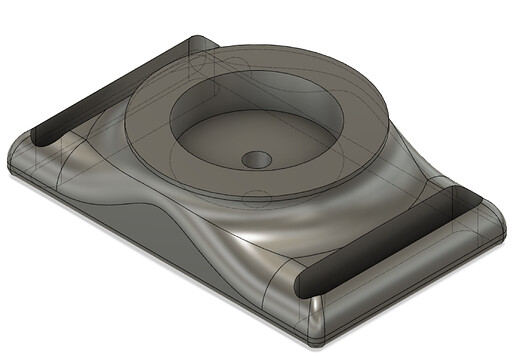

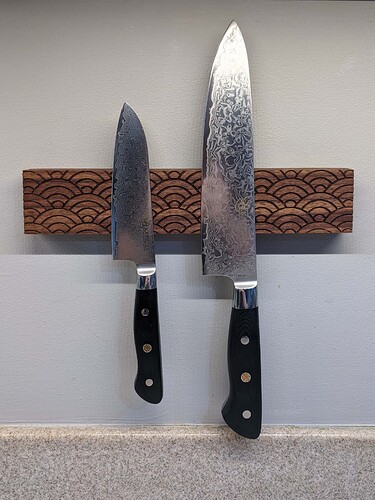

I also thought for a bit about using some of the smaller magnets as replacements for springs. For example these buckles have little springs to keep the golden toggle thingos held in:

And I thought about milling in slots for magnets that would push against each other instead.

Along similar lines, I thought of making a spring-loaded latch that worked with magnets instead of springs.

But in the end, I ran out of time, so couldn’t make any of my other ideas work. Plus, the magnets are a cooler solution than springs but they’re less practical.

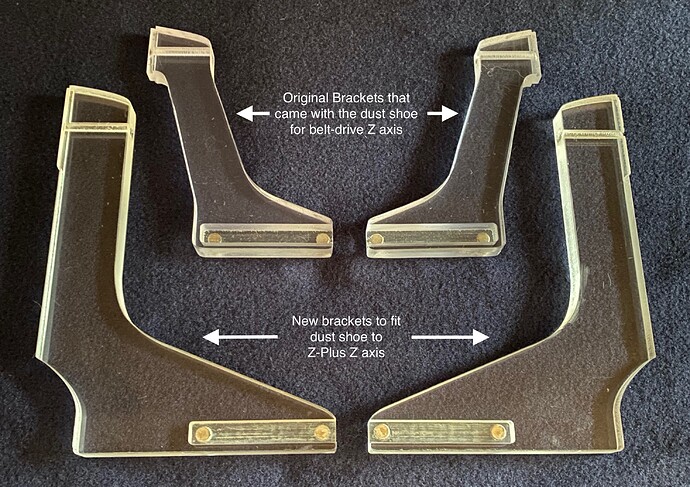

I also considered doing this:

But it didn’t have any need for the Nomad.

I have my hoist and I learned a bunch, so I’m happy.