Some progress tonight.

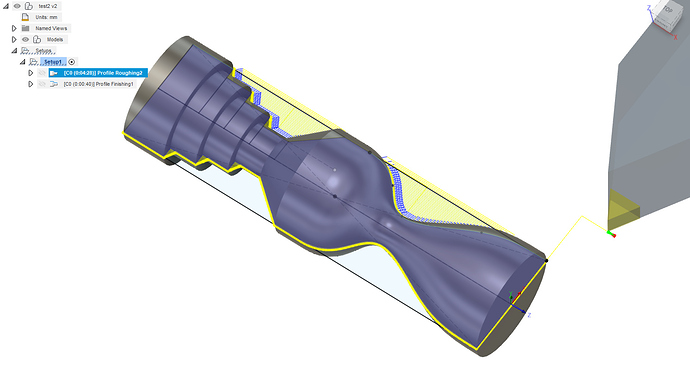

- I modeled a random test piece in Fusion360, and modeled one of my cutters (60degree…thingy, gosh I need to learn yet another lingo)

- Using my hacked FANUC post, I generated the turning toolpath, which revealed:

- that GRBL does not speak turning langage (of course it doesn’t…) so I had to comment out a number of lines like O1001, G98, G50, G28 U0, G99, G96, G97…who needs those anyway (just joking, I did go and learn what they do, and confirmed I should removed them for my very specfiic setup)

- I had already substituted X for Y and Z for X to get back to CNC coordinates, but I scratched my head for a minute when I noticed that the Y values where twice as much as they should have been. A minute of googling later I learned that even though the zero reference for X is the lathe axis, the X value is a diameter, not a distance from X0 (radius)…D’oh. So I hacked the post further to divide all X values (well, Y values, if you followed) by 2.

- at this point, someone at FANUC is yelling at me for BUTCHERING their post processor

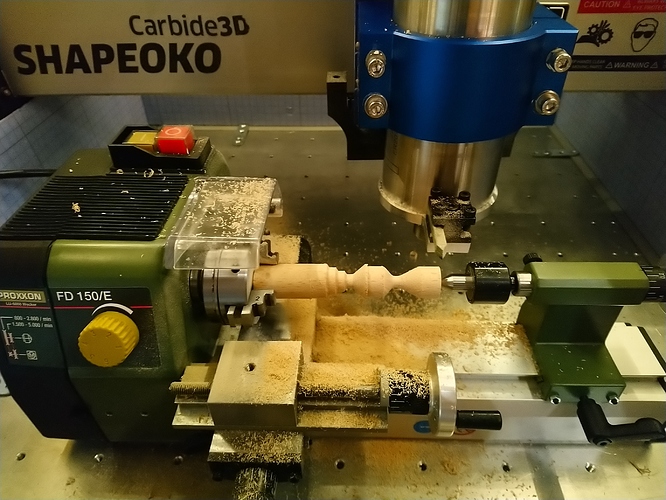

But…it worked !

(sorry no video, I had my hand on the emergency stop and all my attention on the cut)

(and yes the resulting piece does not look 100% the same as the model, that’s because I started from my partially turned blank from the first test)

This is fun!