CNC, like most things, is a sequence of steps — the thing is, you’re turning the execution of some of them over to a robot, one which, aside from homing, doesn’t have any sensors — think of your G-code file as a set of instructions for a blind person to walk through your house w/o a cane — you don’t want them to get hurt, nor to break anything.

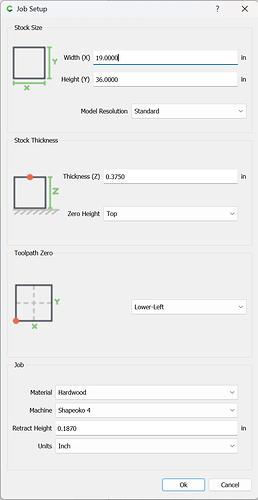

So, when you set up a job in Carbide Create:

you are specifying the origin for cutting.

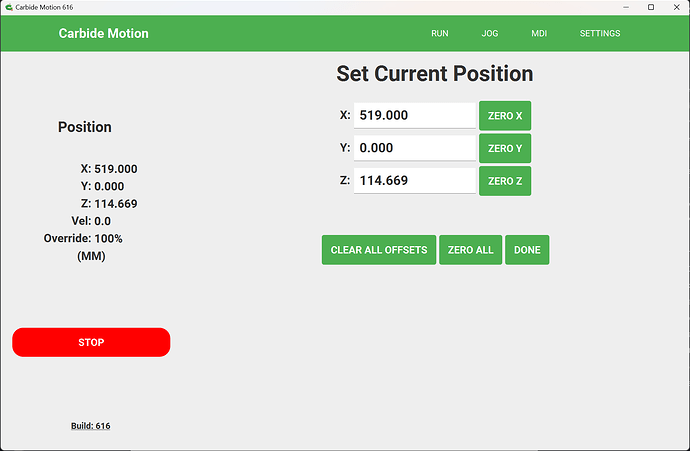

Then, when you set the zero relative to the stock:

that has to match how it is set in the file — if it doesn’t something annoying (the machine will only cut air) or (potentially) disastrous (the machine will try to cut through the material, baseplate, T-track, or clamp).

I tried to record the entire sequence in a couple of posts, see:

and

The big thing is, think in sequence, and consider what the settings from a previous step will require you to do in the future.

The great thing about CNC is that given a properly prepared file, a machine setup which matches the file, and nothing going wrong in the cutting, a part will be made correctly.

The awful thing about CNC is that a part will only be made correctly if the file is prepared properly, the machine set up to match the file, and nothing goes wrong in the cutting.