Yes, that should work.

I’ll give a go tomorrow after work, hopefully, and see how it fairs out.

I’d really like to be able to use Fusion 360 to create a complete g-code file after the design. I’ve been using Fusion for several years now but haven’t tried CAM. Can anyone point to a complete walkthrough lesson that perhaps even uses Carbide as the post processor? tnx

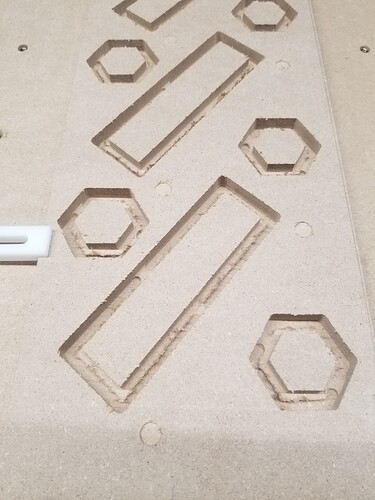

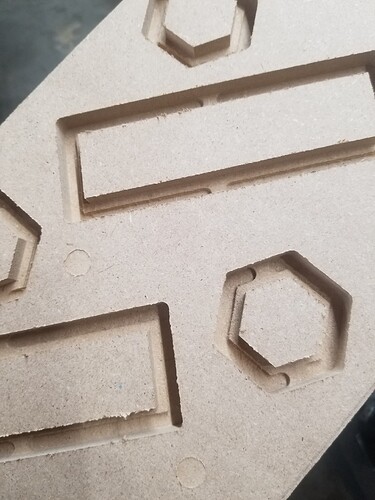

I’m running the file you sent, it got this far into cutting and for some reason, like power blips and restarts, stopping the machine, part unfinished.

Any ideas maybe?

For lost connections, try running an “air job” w/o stock or vacuum or the spindle running — let us know how it works at support@carbide3d.com

I think you’d have to export your sketch in F360 as an SVG, then open that SVG in Create, and go from there.

However, if you’re only using Fusion as a “Hobbyist”, you cannot export it.

I’ll try again in a few. After posting that, I’d ran it again, and left the vac off, until it got to the point it powered off, then turned the vac back on(chip control), and it finished the run. Kinda.

So, it did not actually cut all of the way through, as I knocked out the sections.

I would say that was a successful cut. All you had at the bottom was a thin skin and tabs. I try to attain that each time. I use my calipers on each piece of wood I place on my machine and adjust on the setup screen. There is no sense in damaging the waste board too much, but it happens.

This is what I did to help prevent static issues on my machine.

Grounding your Shapeoko - CNC Machines / Shapeoko - Carbide 3D Community Site

Ahh, makes sense, I reckon. I suppose, I wasn’t anticipating much post processing but, it’s certainly not horrible, and can easily be finished off.

And well shoot, I guess before I attempt to cut anything else, I’ll need to figure out some grounding, as I have nothing for that.

Since I have no grounding at all, do I actually need it for the machine itself, or would I be okay to just order a grounded hose off of Amazon, and from the Sweepy boot to the Dust Deputy?

I used scrap wire I had lying around, you know, I may use that someday type. Terminal ends not everyone has.

Good Luck

To minimize post-processing for this sort of thing, set the origin relative to the bottom of the stock — I showed doing that in:

So, just curious quick, since I have the HDZ(no VFD), I shouldnt have to ground that, right? Read the write up, and watching the video in relation, and I guess, I don’t have a clear understanding on that, or would I just need to ground the X rail, and dust collector hose?

I believe the machine should be grounded all the way around. From Cutter to dust collector to machine to earth. Electricity finds the easiest path. If it is through your control board you have issues.

Alright. Since my HDZ is grounded to my BitRunner, could I splice my X rail to that ground, or bad idea?

Don’t mind the clutter or mess, I am moving… ![]()

So I went from my “Z” plate to “Z” Stepper thru follow wires to “Y” right, under the machine to “Y” left. At this point, you have connected all metal electrically. I then went to the ground on my outlet as well as to a ground rod.

I cleaned a bit of paint at each connection to ensure my connections were touching metal and not relying on only the screw.

I may have overdone it. Better safe than sorry. Worked with computing equipment for many years where poor ground could cost thousands of dollars.

Good Luck Ask if you have more questions.

No judgment haha! I just wondered, mostly since my HDZ is for sure grounded, and what I’d gathered is, with the Y rails and chassis, all tied together, was grounded with the PCB(maybe I misinterpreted that?) but, if I ground the hose to the HDZ, then the X to the Y, and ground from I should be good? Gonna test my outlet tomorrow after work, and confirm it’s grounded. Spoke to my father in law tonight(as he’s an electrician) and he’d mentioned possibly adding a ground rod, if needed.

Also, I’ve seen several using power strips with their machines, and I have mine connected to a Panamax m5300-ex power conditioner, which I use their later model with my theater, and helps against surges/ground loop issues(may be apples and oranges there?)

Off topic, that a '29 back there?

“32” My Dads, to my brother, to my son, to his cousin. Going to get the attention it needs from someone in the family. Loved driving it.

Forgot to mention I traced the dust collection hose all the way to the metal on the Dust Collector motor and to one of my ground rods.

I am unable to comment on the Strips. No experience recently with them.

Nice! Someone’s gotta keep these classics goin.

I should have my antistatic hose tomorrow. Messed up and ordered the wrong connector for my hose to dust deputy but, I’ll have that Saturday. Gonna design and print a temporary reducer now quick, and will see if it’ll work enough to test.

Good Luck And Have fun as I get to 20 char