MeshCAM would easily cut this if provided with the shape in an STL.

Other 3D modeling options would be:

- Moment of Inspiration — this is probably the easiest free-form 3D modeling program

- Blender — free/opensource some folks are successful with this

- Alibre Atom3D — a mechanical modeling program, it might be possible to model this shape

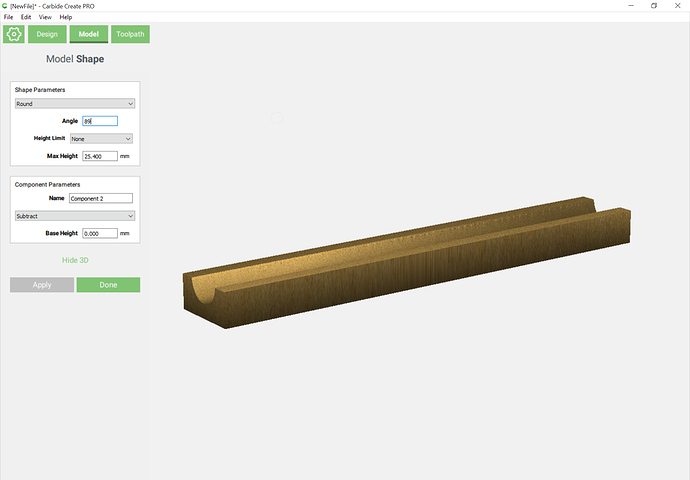

It should be workable to model this using the 3D features in Carbide Create Pro:

In CC406 Carbide Create adds the option of 3D features in a new “Pro” license. Currently available as an open beta for testing at: https://carbide3d.com/carbidecreate/ (see: https://carbide3d.com/blog/2019/carbide-create-400/ for the initial announcement and consider checking out a beta if available)

To activate the features see: https://www.youtube.com/watch?v=9dMVzLTbego and https://launch.carbide3d.com — creating an account will allow a free trial. “This trial is fully functional … so you can generate G-Code and try a full project.”

See: Carbide Create Pro - First Look for some more details.

A video tutorial at: Starting with 2.5 d carving and see Vcarve pro wide flutes for a decorative 3D design.

Pricing discussion for the “Pro” license (the base functionality will remain free): Carbide Create Pro- What do you want to see?

See attached. sample.c2d (12.4 KB)