Been working on some gift coasters recently and thought I’d share the process for anyone hesitant to use epoxy. It’s really not difficult and you shouldn’t hesitate to give it a try if you’re interested in this material.

Although Carbide Create wasn’t used to make these coasters, I did use the method shared by John Clark, @45RPM in this community, to center and cutout each coaster after pouring the epoxy. Here’s John’s post about creating boxes And the specific video about centering the design consistently for each box, or coaster in this case:

Three part video tutorial on box making on the Shapeoko for beginners

And:

https://www.youtube.com/watch?v=sOqT5AVoezU&feature

Making the centering fixture begins at about 10 minutes in, but I suggest watching the complete video as John is a great presenter.

The first step was cutting some .45 stock I had sitting around into squares that fit my fixture on the table saw. Yeah, sorry, could’ve used the Shapoko. Then I flattened each piece to make it smooth and I wanted finished coasters about .375 thick. Just took a few thou off each side, the finished thickness comes later.

Next putting the best grain side up, the cutout for the epoxy is made. The depth was cut a little deeper than the finished coaster thickness, for these about .380 Carbide Tool Source in Grants Pass Oregon sells very nice extended reach end mills that were used for this project.

When pouring epoxy, be sure to have an ambient temperature at least 75F (about 24C) or above to get a proper cure. For this project, I mixed in small batches of 8 ounces or less. It’s really important to mix completely either pouring into a second container and continue mixing or scrap the sides of the container and the mixing tool completely, my preferred method. Only add the color or powder, if using any, after you’ve completely mixed the epoxy. There are many videos covering mixing, so that’s all I’ll say here.

I’ve been using this epoxy available at several outlets, though I bought this through Amazon:

I had a similar problem as mentioned in some other threads using powders as the powder tends to settle to the bottom as the epoxy sets. So I’ve been using metallic acrylic paint, available at most craft stores. It only takes a little drop to get good color in the small batches used for these coasters. It’s easier to add more if needed and the metallic additive is fine enough to be very satisfying once set.

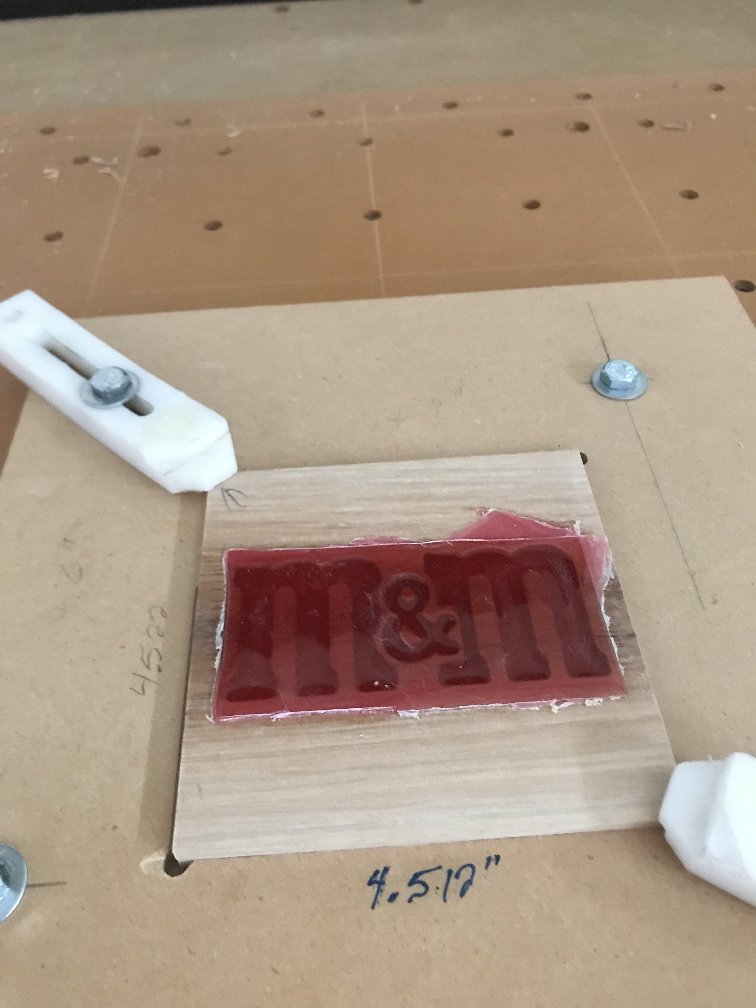

I like to use tape around the edge of the pour area to contain the epoxy and keep it raised above the previously finished surface as the epoxy will soak into the wood slightly and shrink as it sets.

For bubbles, I know some don’t like this method, but it’s working very well for me, yes, I use a torch. Specifically this:

https://www.bernzomatic.com/Products/Hand-Torches/Instant-On-Off/PK8000

I’ll hold the torch tip about 12" above the epoxy pour and holding straight down use short bursts only! Heating the epoxy to much will result in a finish that can’t be saved. I’ve tried with a heat gun, but so far haven’t mastered that tool. Be sure to clean your work area, no sawdust or other flammables, though the tape will burn if to much heat is applied. Remember, short burst is all it takes.

EDIT: Found a post from @fenrus that covers additional basics of epoxy use here

And another from @gdon_2003 here Both of which are well worth checking out.

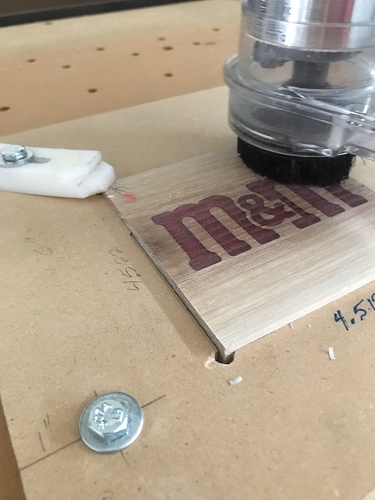

Now the real fun starts! Using a .25 end mill turning as slow as the Carbide Create router will turn and a feedrate of 45IPM surface the epoxy to the level of the wood. I take off an additional .005 to remove any epoxy that might have bleed or been over poured. Not too worried about the remnants of the tape under the epoxy as it is pretty much soaked through and cuts right off with little or no gummyness on the bit.

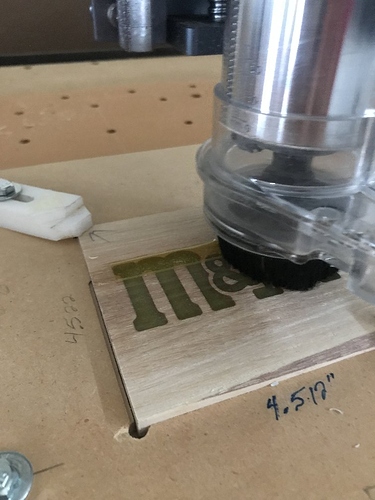

Next flip the pieces you cut in the last step and cut the backside off down to the epoxy. Again, keep your router speed down and feedrate high to prevent melting the epoxy, which is just plastic now that it’s fully cured. You’ll have to do the math to calculate the depth of cut here, but it’s so satisfying seeing the epoxy show through the back!

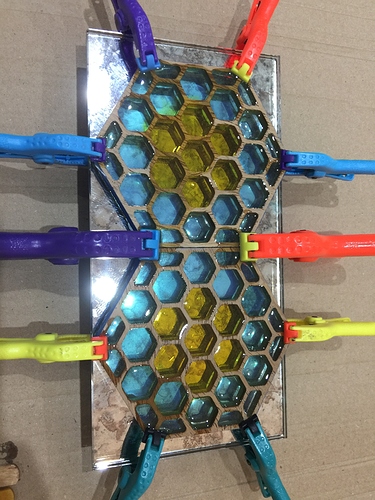

And here’s the result so far:

Notice the machining marks in the last photo? Not great looking, but the trick to make it awesome, is to make it worse first. I sanded each side with 320 on an orbital sander to get this, after flipping back to the original, top side, and cutting out. In this a case using a .125 end mill as slow as the CC router will turn and 35IPM feed. Remember, you’re cutting plastic around the edge and do not want to melt the epoxy, at least on the cats.

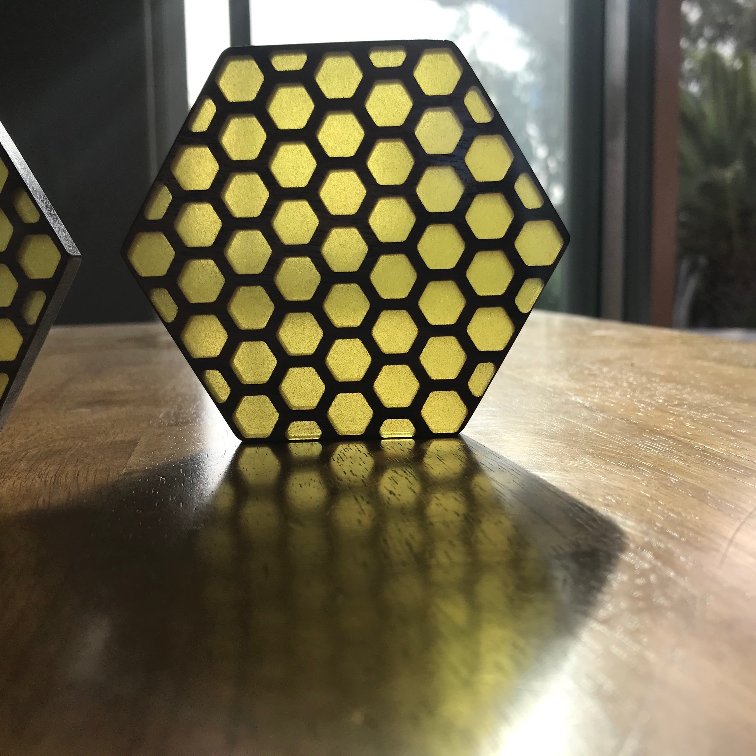

Notice how cloudy the epoxy looks now? Yikes! But two coats of clear gloss poly, with a light sanding using 400 grit between coats gets these glamor shots:

Let me know if you have any questions or if clarification is needed. And please share your epoxy projects