I proceeded to put that CC Pro sweetness to good use.

The other day that thread reminded me that I had a tree cookie (birch) waiting to be milled, and I thought this could be a good material to start from, so I used tape & glue (semi-mistake, more on this below):

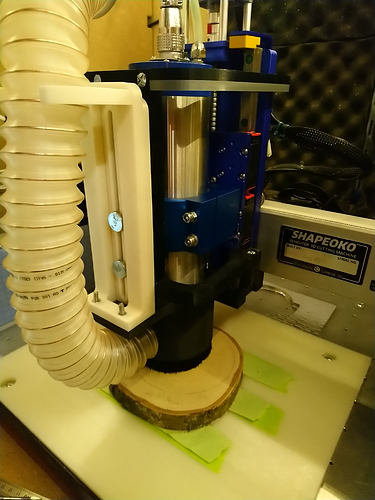

By the way, did I mention I still like my latest dust shoe design? I have not felt the need to “improve” it for a few months, so maybe just maybe my dust collection quest is over.

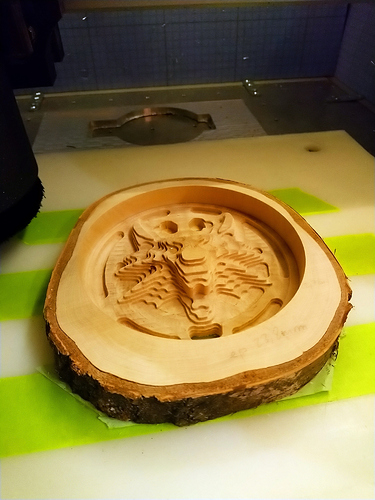

Anyway, believe it or not I don’t think I had ever milled birch before (while very common, for some reason it’s not easy to get birch lumber in small sizes here), and I was pleasantly surprised that it mills perfectly, roughing with a 6mm endmill was uneventful (24.000RPM, 100ipm, 2mm stepover, 1.5mm depth of cut/ stock to leave), it took about 35min:

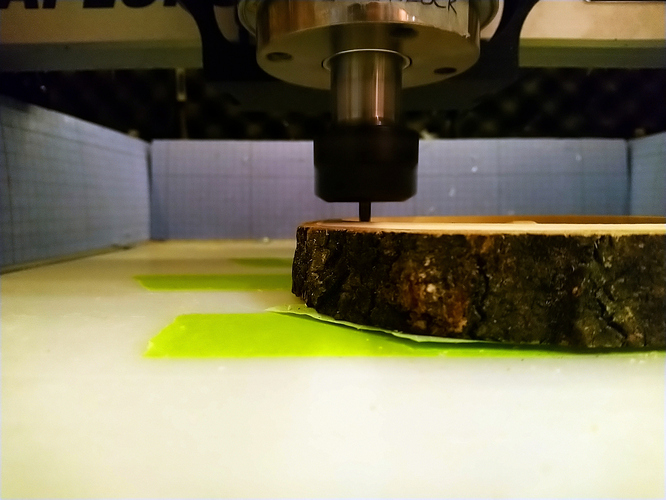

I installed the tapered endmill (0.5mm ballnose tip), luckily it was just long enough for the piece thickness with some margin:

For finishing, I told CC I would be using a 1/32" ballnose (0.8mm, close enough to the size of the tip of my tapered endmill), 10.000RPM, 60ipm, 0.2mm stepover (0.008") and got this:

I decided to run the second finishing pass (same settings but at 90°) to get rid of those fuzzies, and it worked perfectly.

Finally I used a 6mm square endmill to mill a flat on the bottom of the tree cookie.

Overall, close to 5 hours cutting time.

Now came the realization that using tape & glue for this job was a poor choice, I tend to trust it so much that I don’t even consider alternatives anymore. It holds the piece so well that it’s not very suitable for thin or fragile pieces like this one. However, with a little patience, sliding a scraper under the piece all around, I managed to take it off just fine. Phew! close call.

I did a little clean-up of the open parts with a small file, and left the face untouched.

It’s about 6" wide.

I’m pretty happy with the result !