In a previous episode of my dust shoe adventures, I mentioned that someday I wanted to install a camera in there (because even though I really like my 3d-printed shoe, it’s not see-through and that is frustrating during cuts).

I had put that project on the back-burner but then @LiamN recently showed us the LED ring he installed on his spindle, and I was triggered: not only did I WANT the same LED ring, it also put my dust shoe camera idea back on the top of my list, because the little USB “endoscope” camera I had in mind is so low quality that it needs TONS of light to produce a half-decent image. I figured this was the perfect opportunity to kill two birds with one stone.

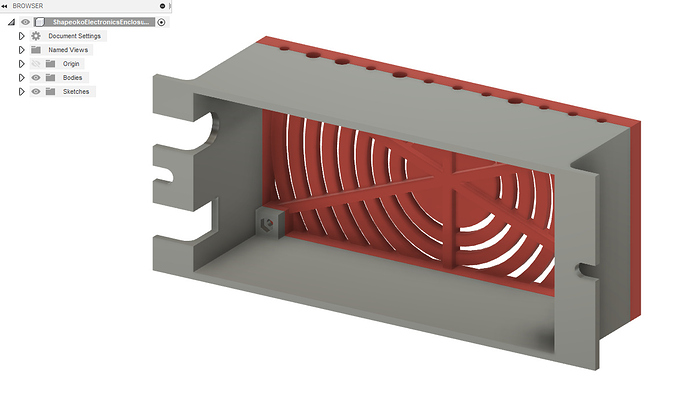

And while I was at it, I would take the opportunity to swap the metal casing around the Shapeoko controller for a 3d-printed version with easier access.

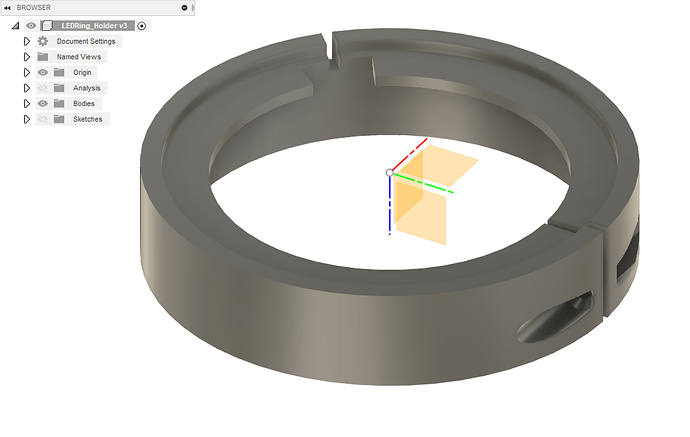

First order of business, sketching a holder/adapter to mount the LED ring on the spindle body:

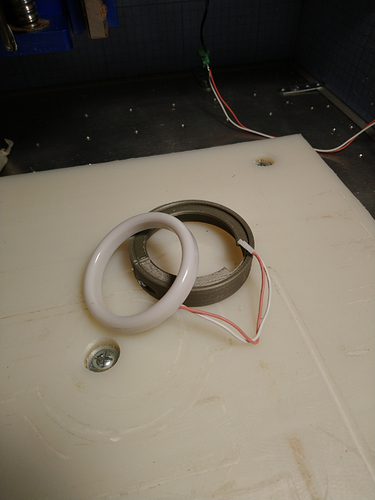

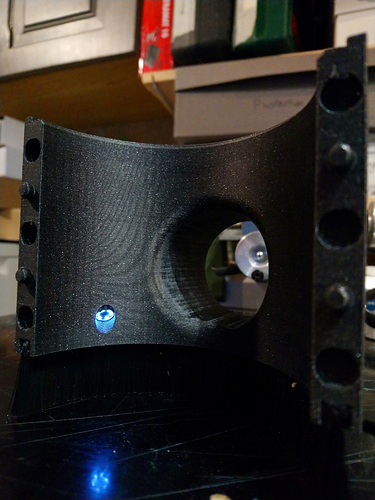

which I printed and test-fit with the LED ring,

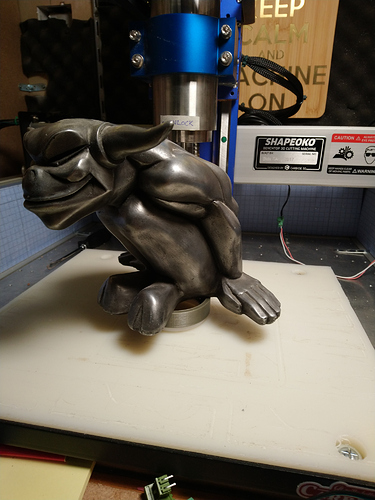

before glueing them together (yeah, I’m not subtle), using my favorite paperweight:

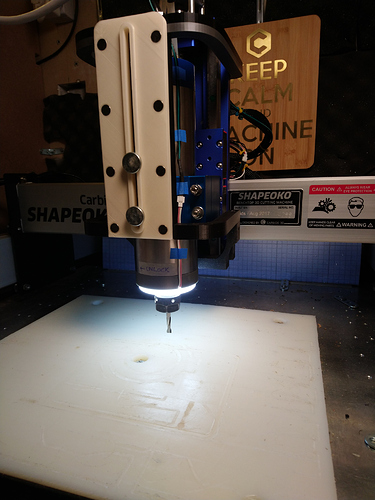

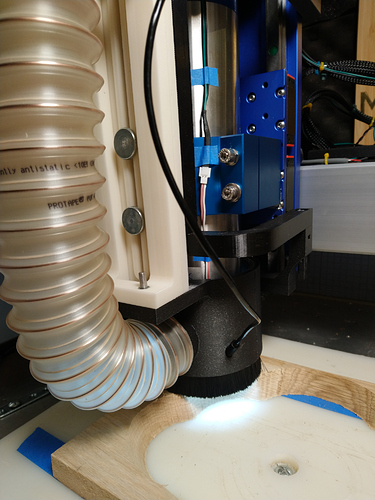

I tested the LED ring to draw around 150mA on 24V, which I figured the Shapeoko controller could handle without any problem so I ran the 24V from the board to the LED ring. And oh boy, the Shapeoko looks about 9000 times cooler with it, I love it!

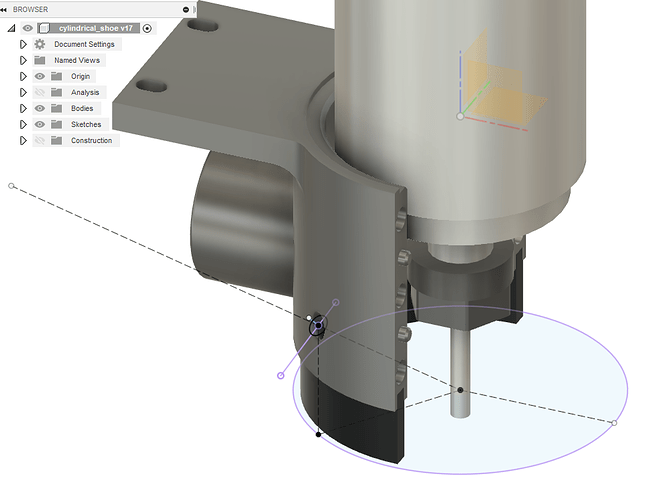

Now to the camera thing, I opened the Fusion design for my custom dust shoe, and draw a cylindrical hole at an angle, aiming at the center of the bottom of the dust shoe:

Re-printed that part of the dust shoe, and installed the small USB endoscope:

So far, so good:

I went on with sketching a simple replacement for my controller’s enclosure,

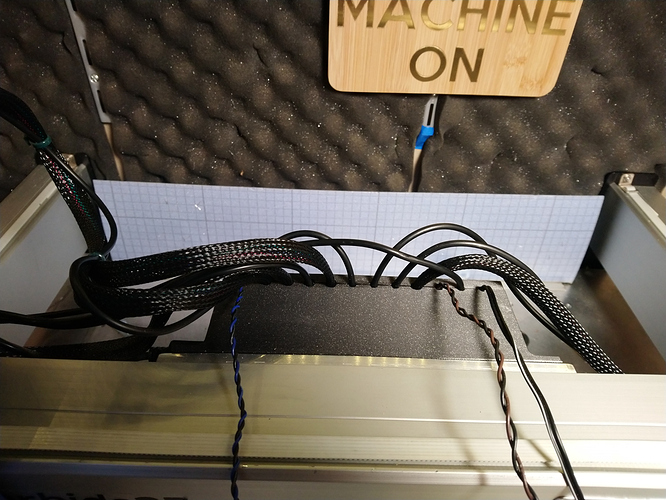

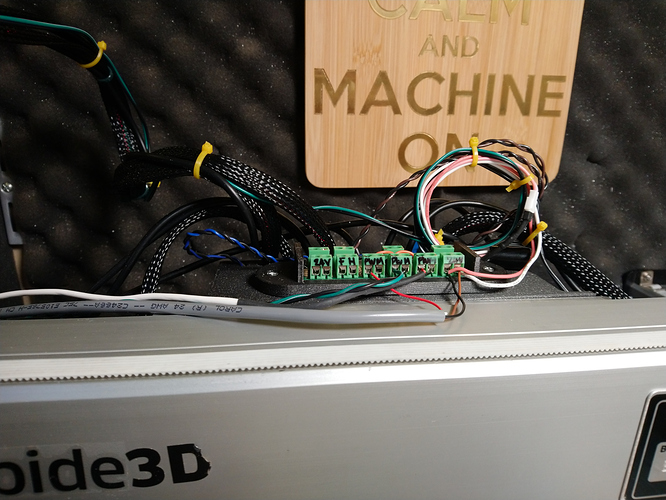

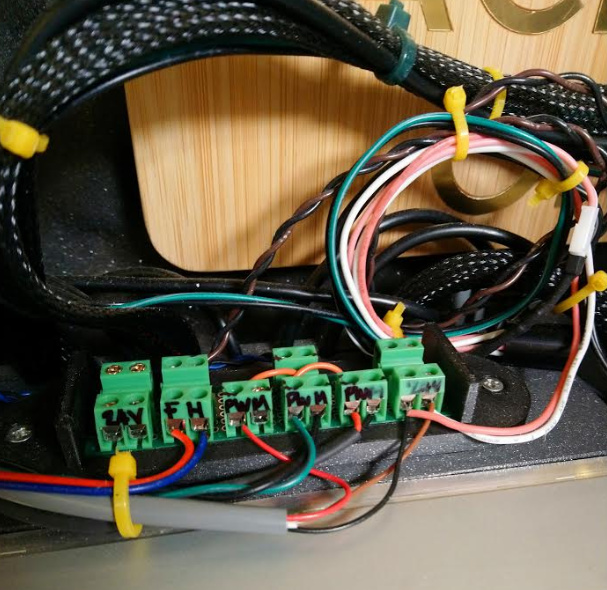

Printed that and rewired everything, using whatever pieces of spare wiring I had on hand, to have the PWM, 24V, and FeedHold signals available outside the box:

Which I plugged in this homemade splitter board (such that I can connect my spindle, laser, and BitRunner on the PWM at the same time)

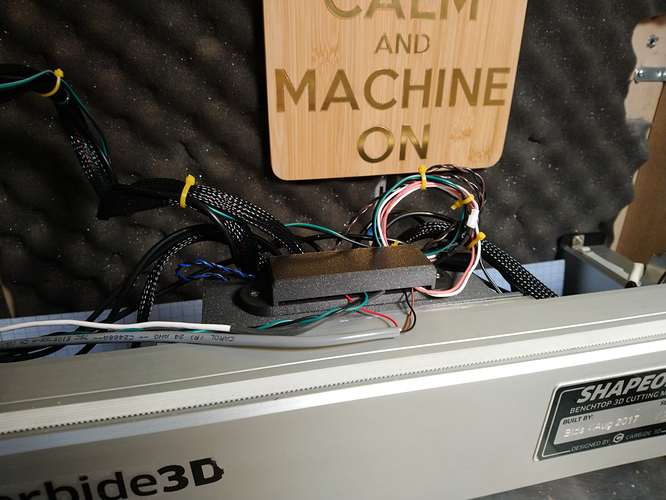

Slightly less messy with the top cover installed:

And it was time for a very first test cut with the camera in there:

WARNING: apparently the sound from that video was taken from my laptop’s mic, and it captured the remote sound of the machine as if it was the most chattery cut ever, for some reason. Turn off the sound. You have be warned

Oh, and ignore the tearout. It’s the most awful test cut ever, but that’s not the point.

This is quite fresh, and it’s getting late so I’ll do more testing tomorrow, but I like where this is going!