The spine of the mirror holder will need to be rounded at least enough to allow a reasonable positioning of the mirror.

There are several ways to accomplish such rounding:

- use a cove radius endmill — unfortunately, Carbide Create doesn’t support such endmill geometry, so no 3D visualization, and not sure if a 4.5mm radius endmill is available. See: Design into 3D: Boxes: Magazine storage for some further information on this

- Export the STL from OpenSCAD and cut using a 3D CAM program, or by using a utility such as: Cutting STL models with Carbide Create Pro (nearly-2021 edition)

- manually program the G-code to round things off

- draw a succession of geometry and suitable toolpaths to cut this — this is the technique which will be used here

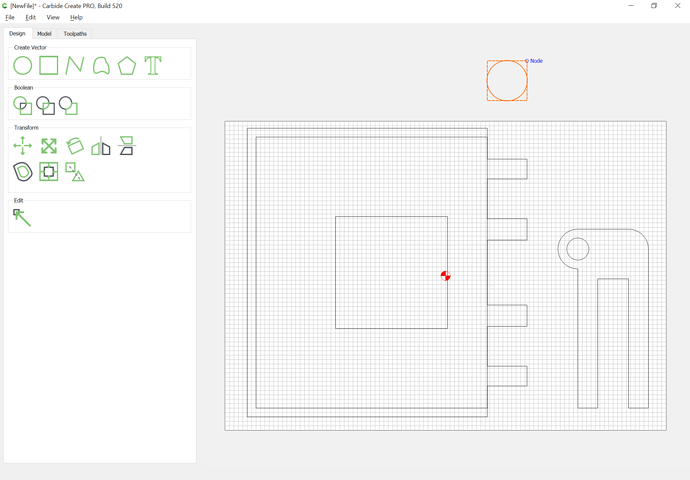

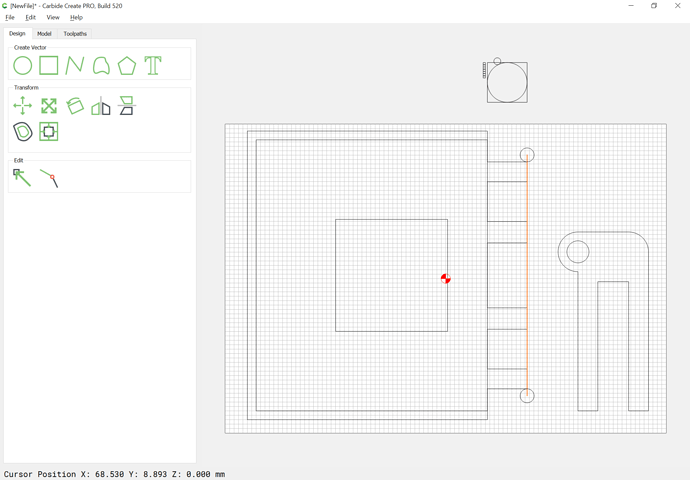

Visualizing this will be easier if we rotate things to line up and draw in the geometry in register:

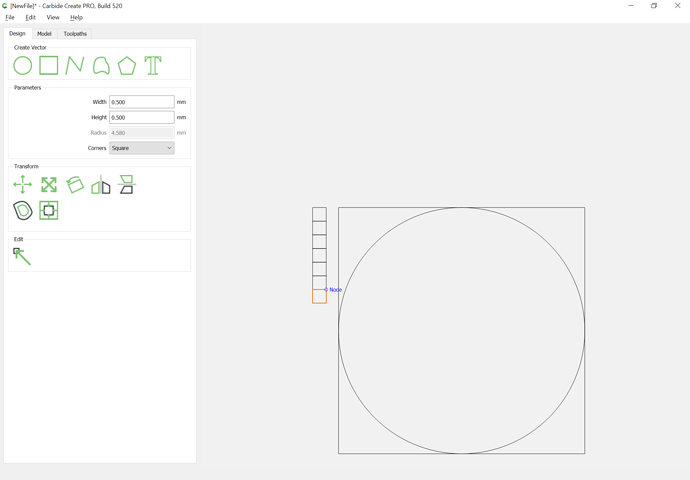

The depth per pass is 0.508 mm for a #111 ball-nosed endmill — rounding down we want a stack of 0.5mm squares to indicate the depth we will be cutting to:

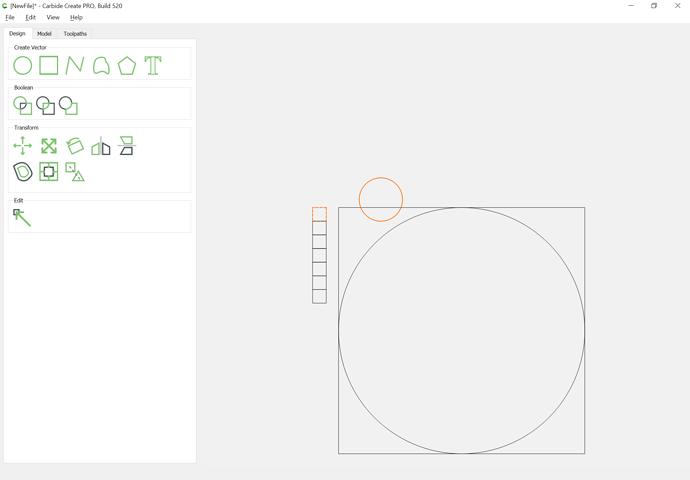

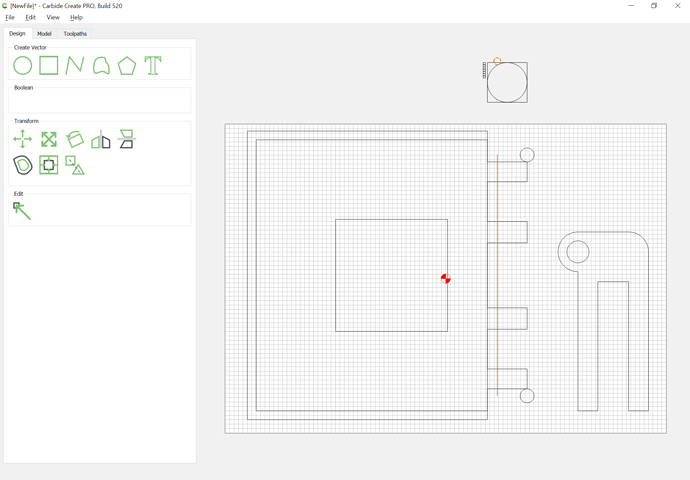

Drawing in a 1.5875mm diameter circle we align it with the bottom of the top rectangle:

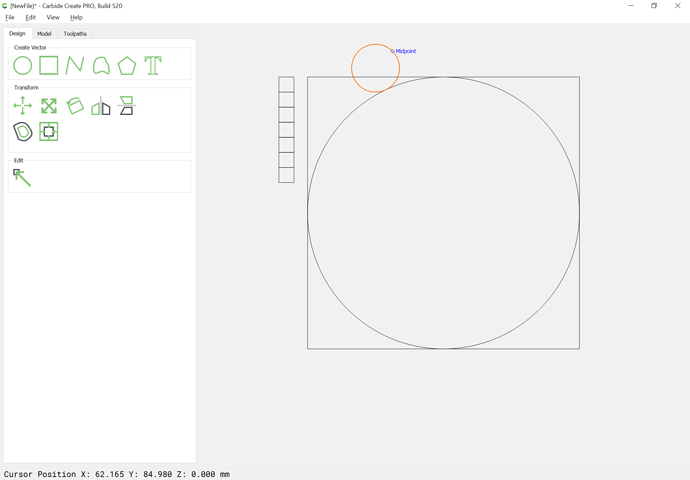

and then nudge it over until it just touches the circle which represents the desired rounding:

Draw a line which is radius longer than is needed at each end:

align it with the center of the circle:

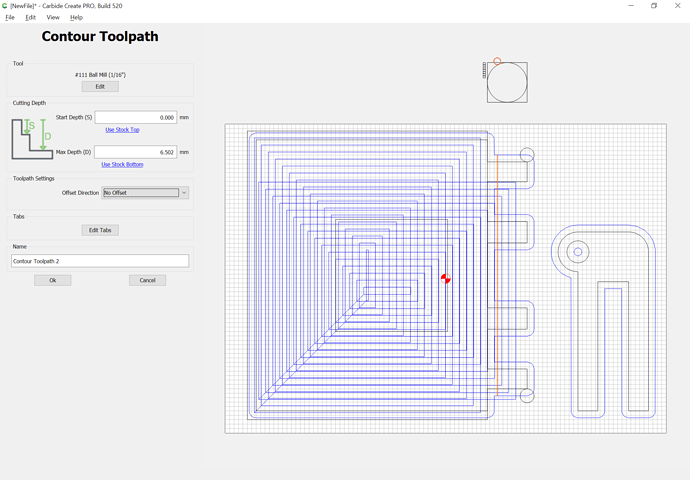

and assign it a Contour No offset toolpath to a depth of 0.5mm:

Repeat for each depth square.