brparki

January 8, 2026, 8:08pm

1

I’m using Solidworks to create in. I’m trying to do a single curved cut on a 2x4 for an arbor.

WillAdams

January 8, 2026, 8:26pm

2

If you have a 3D CAD package, why not use a 3D CAM tool?

Either Carbide Create Pro:

or MeshCAM?

Just export an STL and be done w/ it.

Note that writing G-code in Grbl is not that easy/pleasant — there are no variables, loops, or any sort of branching, it’s an exercise in tedium (I’ve done it), alternately c.f.,

Library for interpreting G# macro-programming CNC language into plain G-code lines

and FWIW, I’ve been working on:

OpenPythonSCAD library for moving a tool in lines and arcs so as to model how a part would be cut using G-Code or described as a DXF.

That said, I often fall back on techniques such as:

I’d like to make a wooden spoon and was wondering if that’s possible to do with the standard CC? Can it be done with a bowl bit? I don’t have one but can pick one up. Thanks!

or

Given a prototype base:

[image]

How to make it in Carbide Create?

First, we have a pixel image with some dimensions:

[F-86 base scan with measurements]

We import that into Carbide Create:

[image]

using “Set Background”:

[image]

and adjust for size:

[image]

[image]

It’s then a matter of drawing and toolpaths and so forth (we will try to do it w/o Create Pro, but will also show that).

For reference, there is an overhead view as well:

[DSC00036]

If you’re still stuck, upload an STL and we can look into it w/ you.

Tod1d

January 8, 2026, 8:46pm

3

Is it a 3D shape you need to export?

If not, SW can export dxf from a face, sketch, drawing or flat pattern.

CC can import .c2d, .dxf, .svg

Can you show the sketch or drawing?

brparki

January 9, 2026, 3:16pm

4

I have no intention of buying any more cad programs to further this project since I’m already familiar with SW, but if I have to I will.

Importing a dxf file to Carbide Create without a closed loop always ends with:

Import Warning

Which is a dead end and why I’m here.

ArborPart1.DXF (21.4 KB)ArborPart.DXF (21.2 KB)

WillAdams

January 9, 2026, 3:35pm

5

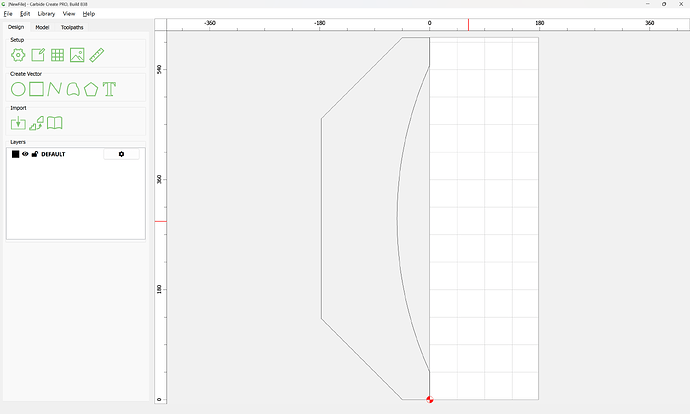

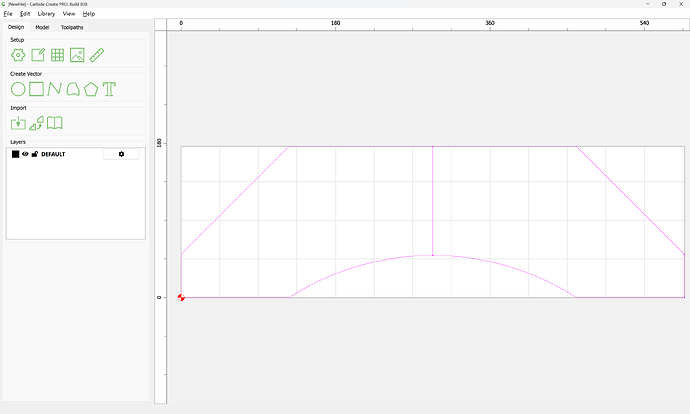

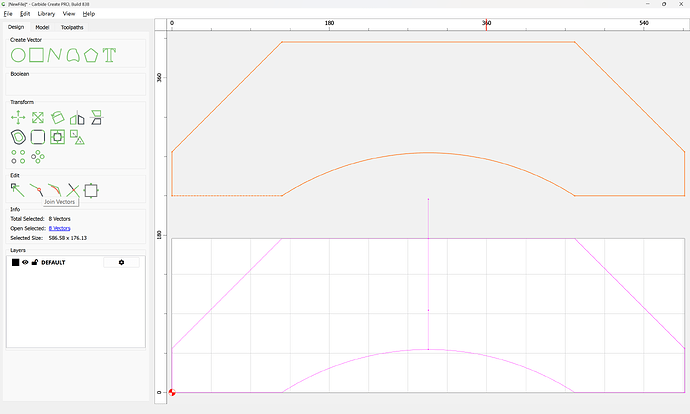

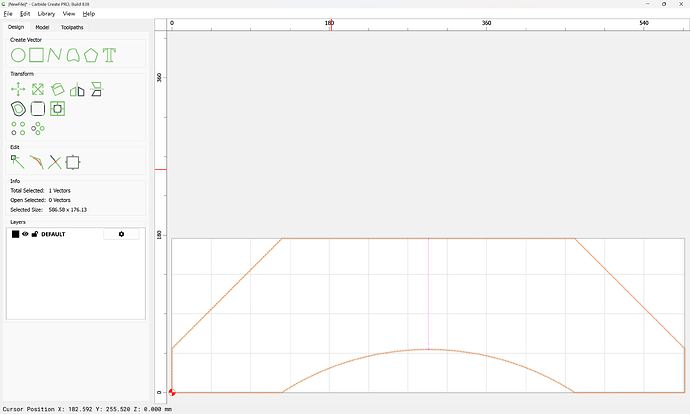

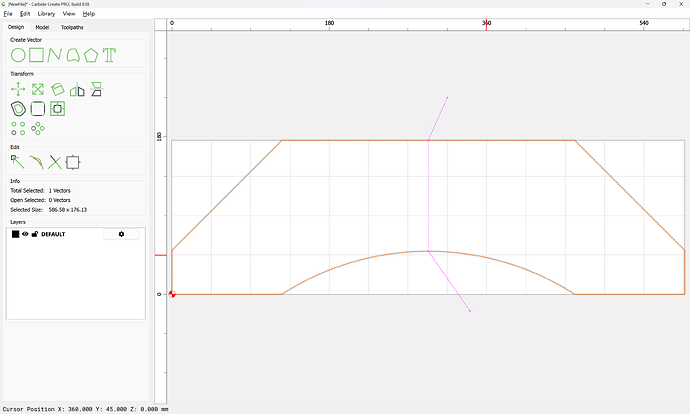

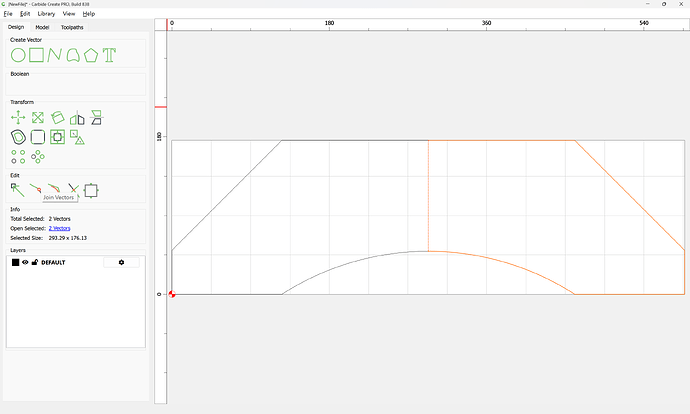

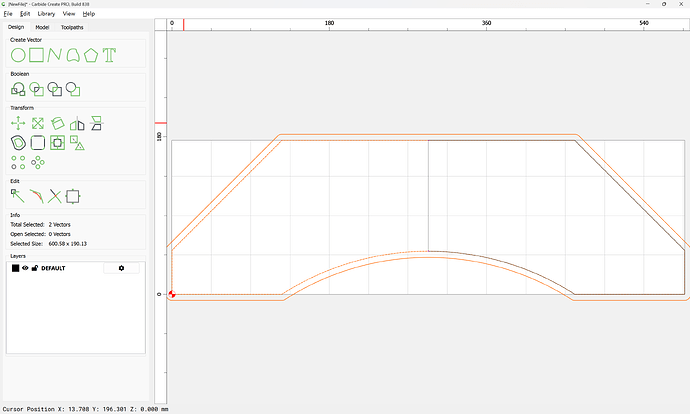

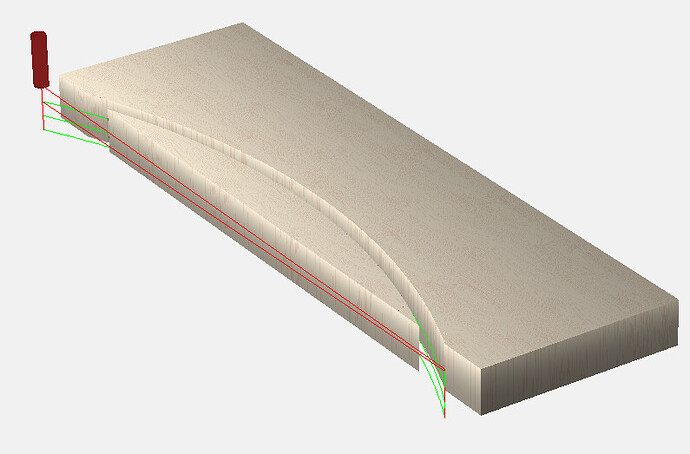

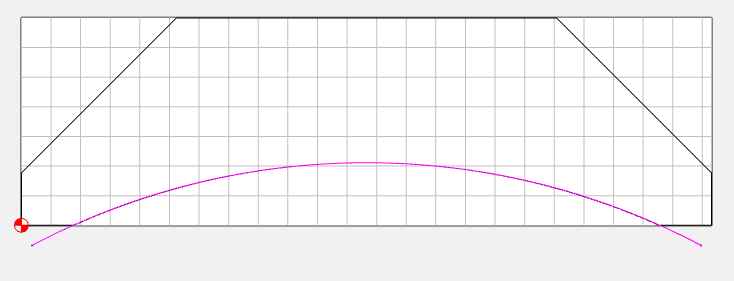

ArborPart.dxf imported as expected:

ArborPart1.dxf imports as described:

I am going to assume that what is needed is two levels (a screengrab showing the part in 3D, or an STL would help a lot).

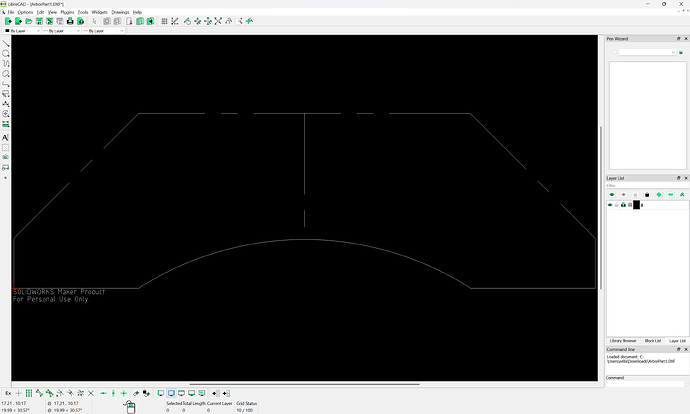

Opening in LibreCAD doesn’t communicate anything to me:

and exporting an SVG from it and then importing yields much the same:

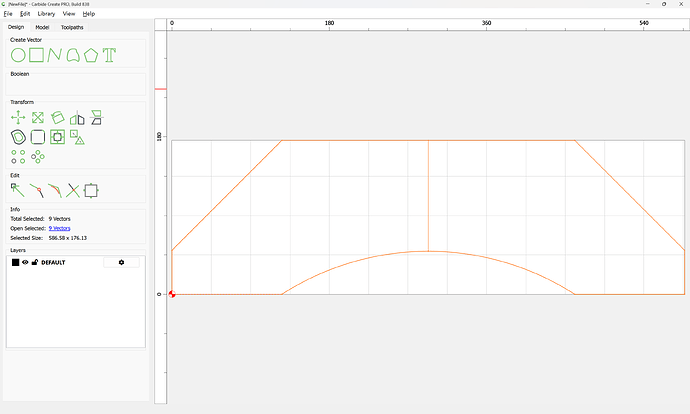

If we nudge things around with the arrow keys so that we can select only the perimeter geometry:

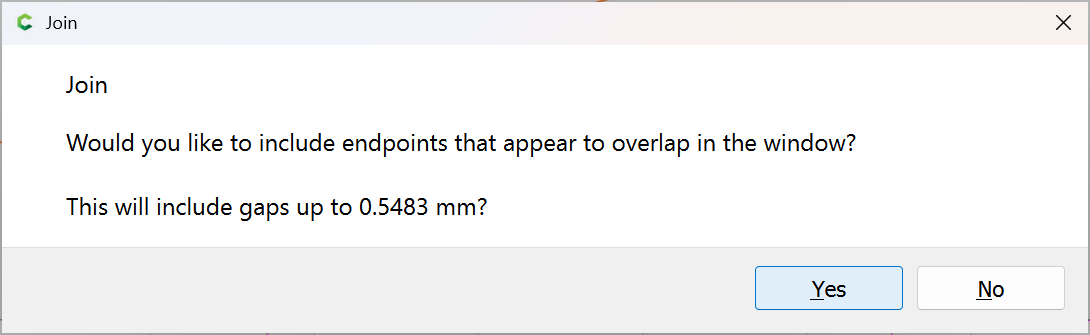

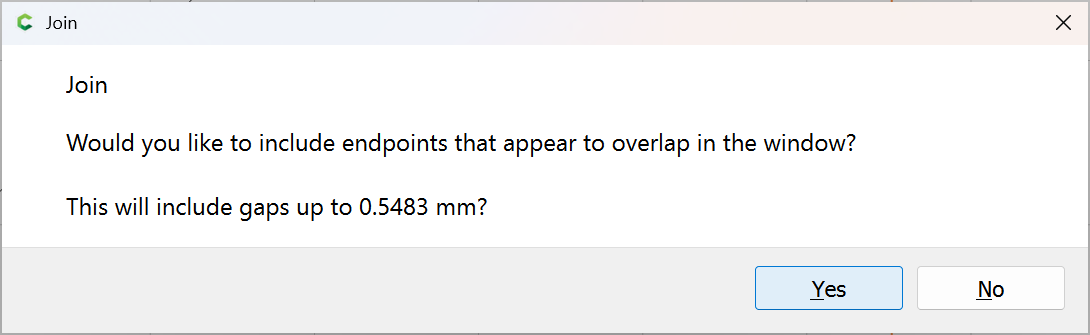

Then use Join Vectors:

Yes

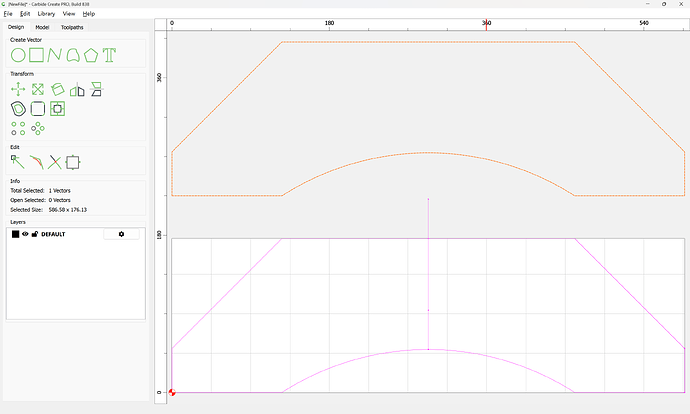

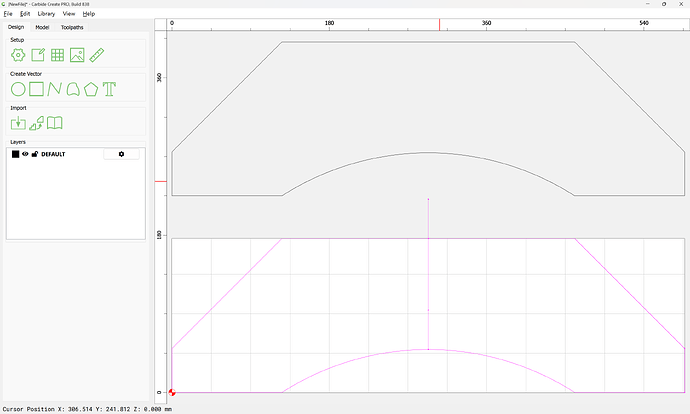

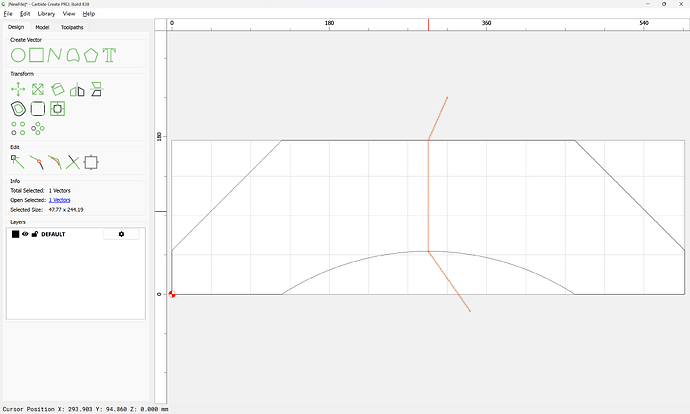

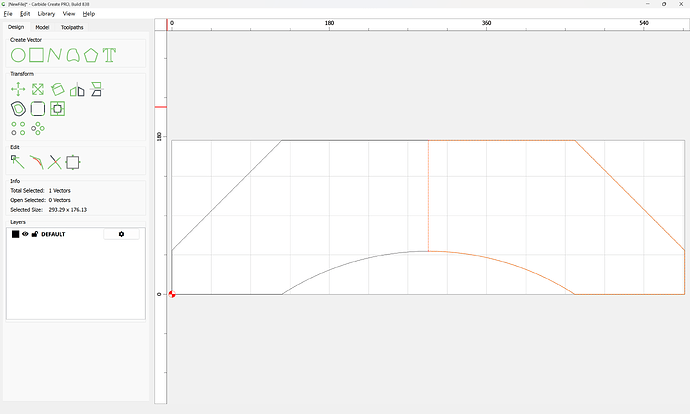

Cleaning up we arrive at:

If we actually need the division, then it is a simple matter to duplicate the closed geometry in place:

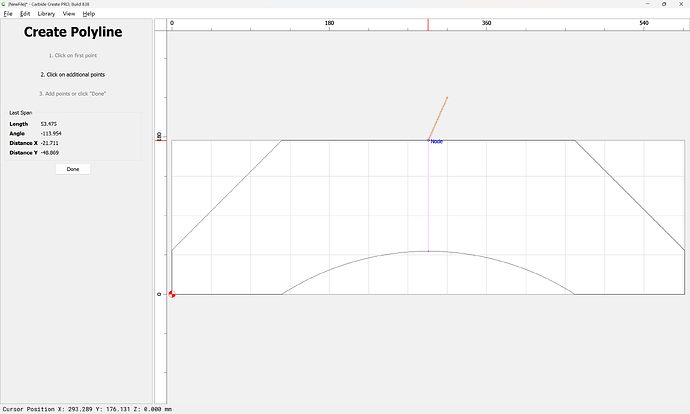

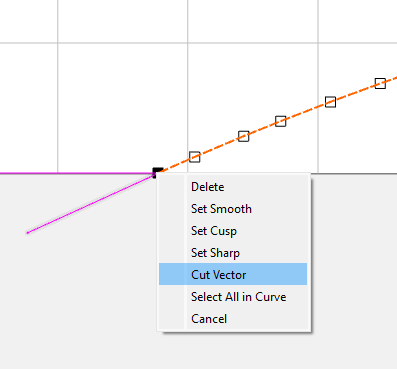

Use Snap to Node to draw in geometry which defines the division based on the open line:

Done

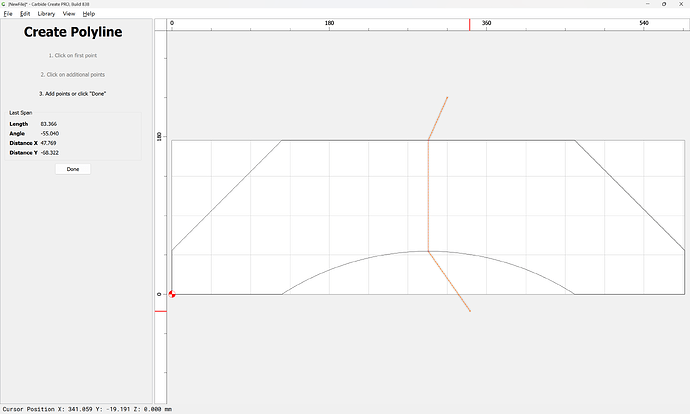

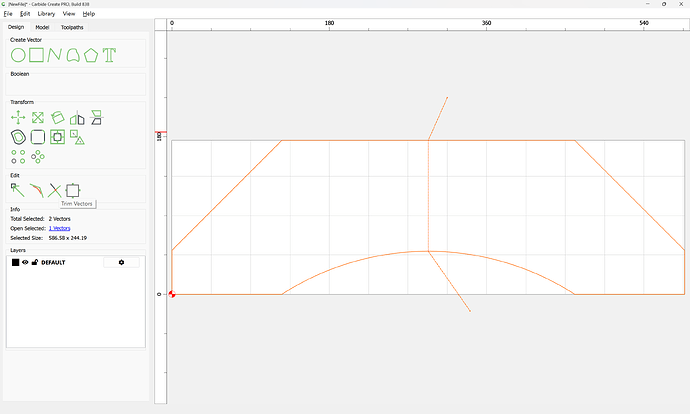

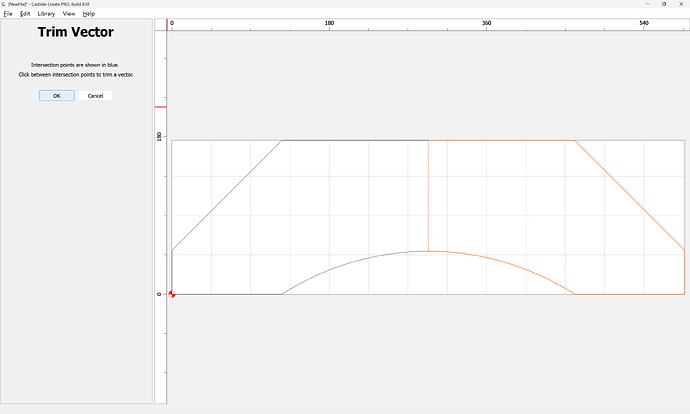

Select one of the duplicated perimeters:

shift-click on the drawn line to add it to the selection:

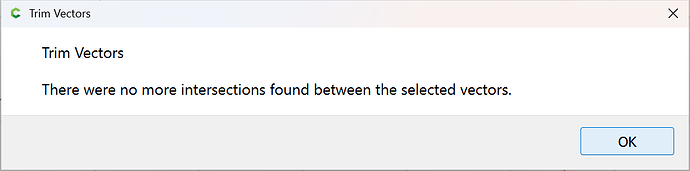

then use Trim Vectors:

to remove what is not wanted (we will keep the right side)

until we arrive at:

OK

OK

Use Join Vectors again:

Yes

Select the original perimeter:

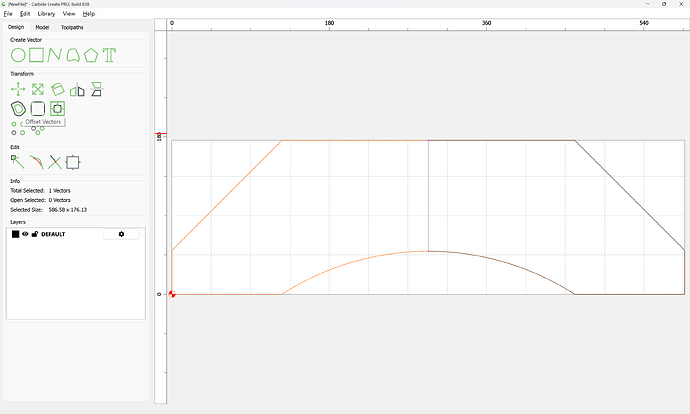

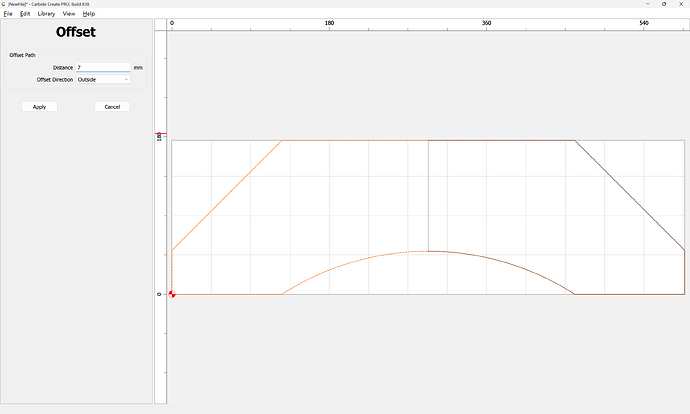

Offset to the outside by tool diameter plus 10%:

Apply

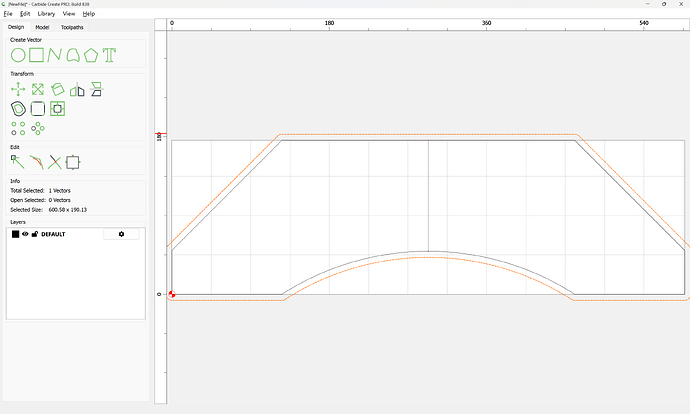

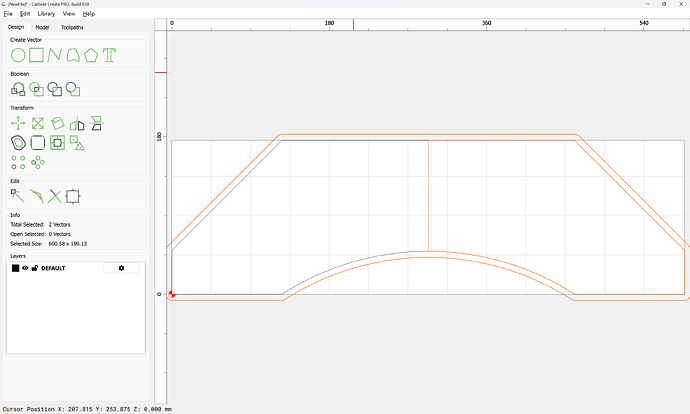

Add the trimmed section to the selection by shift-clicking on it:

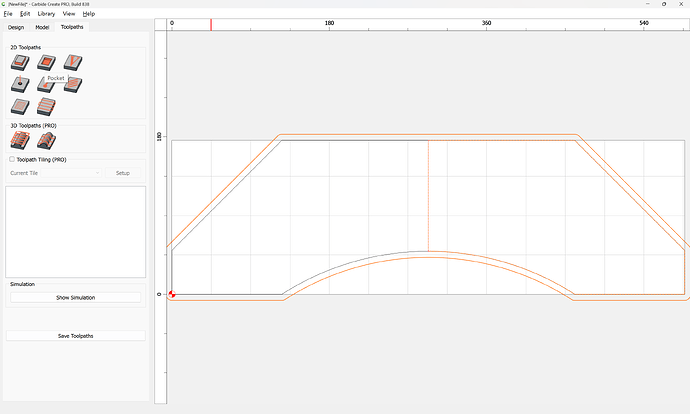

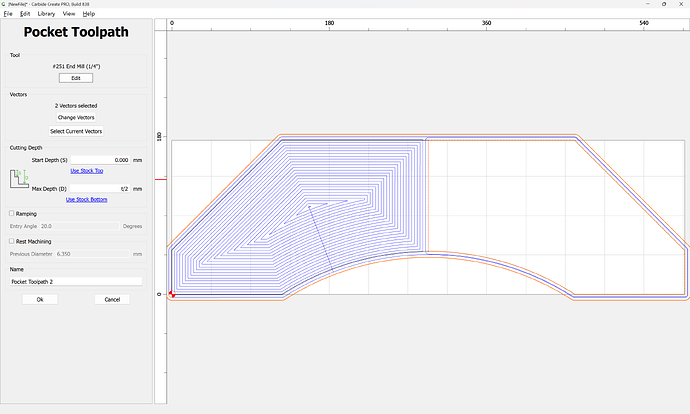

Then make a toolpath which cuts as deeply as is needed (we will assume halfway through the stock):

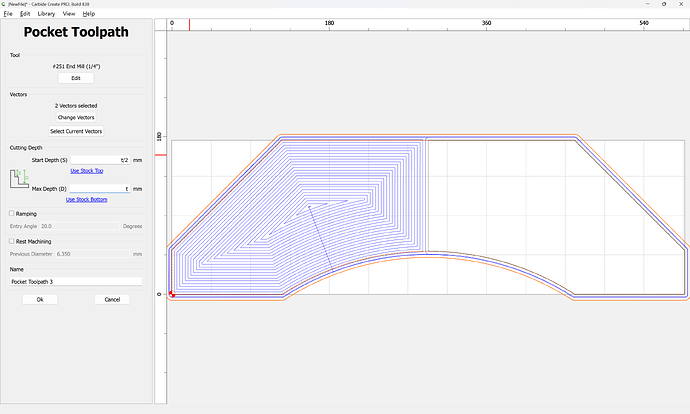

Then select the perimeter and the offset geometry:

and finish the cut (assuming tabs are not needed):

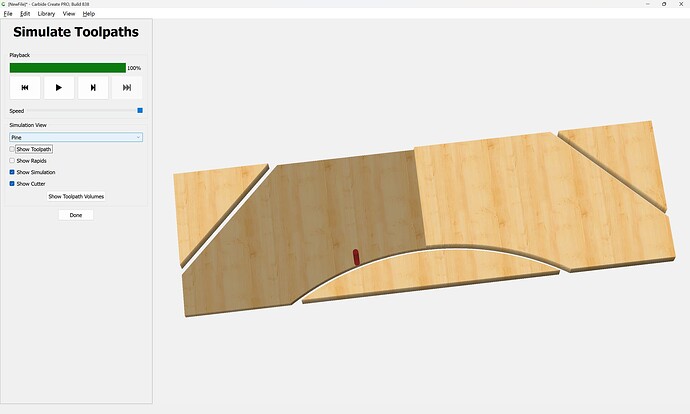

which simulates as:

attached as a v8 file.

ArborPart1_v8.c2d (260 KB)

1 Like

Tod1d

January 9, 2026, 3:35pm

6

Presuming this is the toolpath you’re looking for…

You don’t need closed vectors to do a contour toolpath.

You can also just edit the existing vector, cut it at the arc ends, and add small lead-in/lead-out vectors.

2 Likes

WillAdams

January 9, 2026, 3:36pm

7

FWIW, this would be quite simple to draw in Carbide Create if one had a dimensioned drawing:

have been asked to help with an oar holder project. Here is the part that I would like to use CC to design and then cutout. Using this to learn…much more complex than what i have previously done. Not totally sure how to start. Maybe start with Create Curve and then the note editor??? Just looking for basic direction. tx.

[oar holder layout]

as requested on support…

… some cabinet side pieces that I’d like to use for a shoe rack. Would like some help on how to draw and cut the angled dadoes in the sides of the cabinet. Would also like some guidance on tiling these pieces as they are 8’ long. Everything is 3/4" Baltic Birch and I believe the depth will be 15".

This is pretty straight-forward.

Set the stock:

[image]

[image]

Draw in geometry for the side cuts — this can either be done as continuous (if one is using Carbide Cr…

or:

as requested on support…

Given a design:

[file]

we first draw a circle with the specified radius:

[image]

and center it in a suitable working area:

[image]

Then import the pixel image for reference:

[image]

adjusting as needed:

[image]

Then draw in the rest of the geometry using the specified dimensions:

[image]

[image]

Centering as needed:

[image]

[image]

[image]

[image]

With all the dimensions marked out, select the circles, copy-paste them into place:

[image]

a…

WillAdams

January 9, 2026, 3:41pm

8

Note that MeshCAM is made by one of the partners at Carbide 3D and is bundled with the Nomad, moreover, there is a warning for this sort of difficulty:

https://carbide3d.com/blog/carbide-motion-bounds-checking/

1 Like

WillAdams

January 9, 2026, 6:16pm

9

Or, for drawing this sort of thing:

as requested on Facebook:

I’m trying to make a square 29.75 tall and 33.50 wide but at the top of the square I want a .75 camber across the top?

Draw the rectangle:

[image]

Set the grid to 0.75"

[image]

Move the midpoint of the top so that it is on a grid intersection:

[image]

[image]

Go into Node Edit mode:

[image]

right-click and choose “Insert Node”

[image]

[image]

Drag it up to the correct position:

[image]

[image]

If need be, select, toggle smooth, and adjust the…

Randy

January 9, 2026, 6:35pm

10

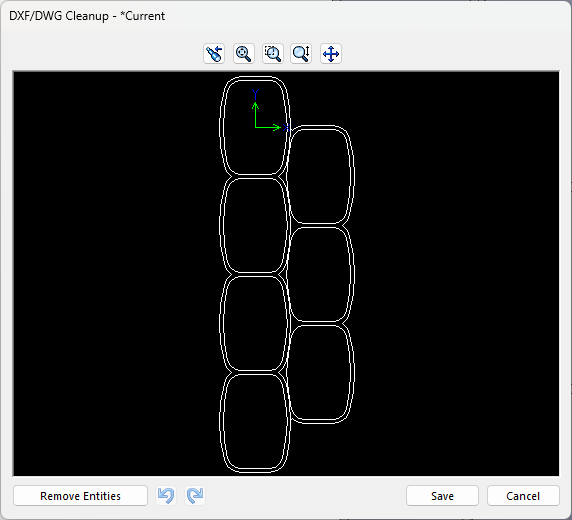

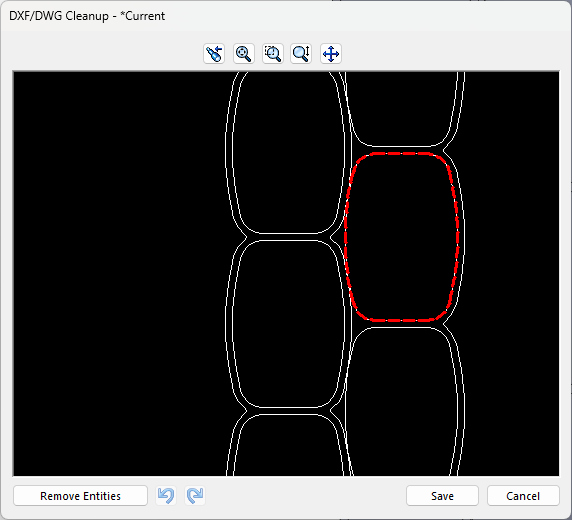

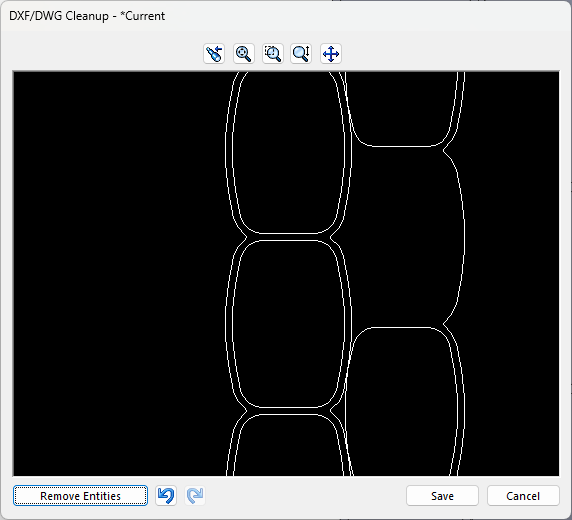

When you output a DXF from SW, there is a Remove Entities check box at the lower left

It can be a little laborious, but ctrl-select the lines you don’t want and then hit that button

Personally, I import SW DXF’s into my old VersaCAD 2D program for massaging…

1 Like

brparki

January 10, 2026, 5:21pm

11

Thank you, thank you!!

Oh, how I love a breakthrough after a serious mental block.

WillAdams

January 10, 2026, 5:37pm

12

One concern about using Open Vectors — typically they only allow a slotting cut — where possible avoid slotting and add geometry and cut as a pocket

While cutting up vacuum extension wands for this is expedient, it’s a bit problematic given that Shop Vac recently filed for bankruptcy, was bought at the last minute, and production hasn’t caught up.

I need a receptacle for the Sweepy 2.0 dust fitting — one option would be to purchase one from Woodcraft, but Carbide 3D sells blocks of HDPE:

which looks to be just barely big enough for things to fit.

Measuring the hose fitting I get a diameter of ~63.5mm — offsetting that twice we arrive at…

and/or

One technique which is often suggested to avoid slotting is to add geometry around a part which one wishes to cut out and cut as a pocket down to tab depth — here’s one technique for that.

In this case, the project is a bevel gauge which will be cut out of 0.0625" (~1.5mm) thick aluminum:

[bevelgauge]

Due to the narrowness of the angles, an 0.03125" endmill has to be used, so after importing and scaling the file (we will be cutting out one which is 3") we select the perimeter and offset it tw…

and consider leaving a roughing clearance and taking a finishing pass.

One which has a cutting flute length equal to or greater than the thickness of the stock — pretty much any tool should work.

Big thing is the toolpaths — if cutting out, rather than just cutting a slot:

[image]

Offset to the outside by endmill diameter plus 10% or so:

[image]

[image]

[image]

Then cut as a pocket:

[image]

down to tab height or the penultimate pass:

[image]

then move the contour down to below the pocket and start cutting at the bottom of the pocket:

[image]

and…